Keep in mind the use of broiler equipment in order to reduce the probability of equipment maintenance

%AM, %06 %403 %2022 %08:%JanThe advent of broiler equipment has helped farmers solve many problems, and it has also increased the survival rate of chickens, so it is deeply loved by farmers, but no matter how good the equipment, if you want to extend its service life and reduce its maintenance rate, Then we must first grasp the main points of the use of broiler equipment. Next, our broiler equipment manufacturer summarizes it for everyone. I hope you can read it carefully and look forward to your reading. Thank you for your support.

Precautions for the use of broiler equipment: We know that broiler equipment contains many conveyors and egg collectors. In order to reduce the wear of these equipment, we should fill the transmission parts such as gears in the conveyor with lubricating oil every month, as well as broiler equipment. Lubricating oil needs to be filled regularly, and regular cleaning should be done; clean the surface of the conveyor and collector in time to prevent debris and eggshells from accumulating on the surface of the conveyor belt, causing additional power consumption or directly damaging the conveyor device.

Floppy disks and broken egg collection trays may leave residual eggshells, straw scraps and other debris, which need to be cleaned from time to time to ensure the performance of the collector; we all know that the direction of wind in each season is different Therefore, we need to properly adjust the location of the ventilation system by separating the seasons and wind directions. In fact, these are detailed issues, but they can directly affect the service life of the broiler equipment, so we should not ignore these issues.

There are many hot days in summer, pay attention to the use of ventilation and cooling equipment to properly ventilate and cool the chicken house, and regularly use automatic chicken raising equipment to disinfect the chicken house, always pay attention to the status of the chicken flock, and take timely measures if any abnormalities are found ,respond. Conditional farmers can install a fully automatic environmental controller, which can monitor and record the humidity, temperature, etc. in the chicken house at all times after networking; fill the broiler equipment with butter for maintenance, and the motor bucket can drop a few drops of vegetable oil to prevent rust. Check that the buckle of the material line and the screws of the lifting system are tightened again, and check whether the line switches and contacts of the material line control are loose to prevent poor contact.

How to manage chicken flock disease when raising chickens in layer cages

%AM, %30 %425 %2021 %09:%DecWhen using layer cages to raise chickens. Improper handling of chickens can easily get sick. So when the chickens become ill, farmers must pay attention to breeding in addition to timely medical treatment. So what should be the most reasonable?

1. Feed: Once a lot of diseases occur, the temperature of the chicken population will rise, and then the metabolism in the body will also be disordered. Therefore, farmers can modify the nutrients in the feed and their content and feeding methods to increase the energy level, according to the diseased chickens The energy level should be increased to 1.2 times the normal level of the decrease in feed intake. There is to add vitamin content. Vitamin A and B vitamins can be added to 3 times the normal amount, vitamin E can be added to 5 times the normal amount, and appropriate amounts of vitamin C and vitamin D3 can also be added. The third point is that farmers should also pay attention to appropriately reducing the fat content in the feed.

2. Drinking water: During the period when the chickens are sick, farmers should pay attention to ensure that the drinking water of the chickens is normal, and the chickens should not be dehydrated, and the water in the drinking fountain should be sufficient and clean.

3. Management: Generally, increase the ventilation of the chicken coop during the chicken disease period, and keep the air fresh, but in winter, pay attention to the heat preservation of the chicken coop and try to prevent the direct attack of the cold wind on the chicken. In summer, try to lower the temperature of the chicken coop to prevent heat stress. When chickens suffer from respiratory diseases, do not carry out aerosol immunization and disinfection with chickens.

The above are the key points for handling the chicken flock's disease period described by the chicken cage manufacturer for the farmers. I hope that the above description can bring some help to the farmers, so that the chickens can heal more quickly and restore normal growth and production functions. Thank you your attention!

Ways to prevent damage to eggs and the causes of damage

%AM, %30 %405 %2021 %08:%DecThe poultry equipment manufacturers have discovered that there are many reasons for the damage of eggs caused by careless management in the daily process of raising chickens. The eggs are affected by the health of the chickens, and the hardness of the eggshells will also be different due to the health and quality of the chickens. , Here are some methods for farmers to prevent egg breakage and the causes of breakage.

- After the start of laying, as the week age increases, the surface area of the egg will also increase, and the strength of the egg shell will decrease. Therefore, the older the laying hens, the higher the breakage rate. The egg-laying posture of the chicken. Different qualities and postures when laying eggs will vary among individuals. For caged chickens, standing or squatting higher, than lying or squatting lower, the egg breakage rate is higher. Time of laying eggs. The hen lacks the light needed to absorb calcium at night, and the eggshells formed are thinner, so the breakage rate of eggs laid in the afternoon is lower than that of eggs laid in the morning. Health status. A variety of diseases have an impact on the quality of eggshells, such as infectious bronchitis, which can cause abnormal egg structure, irregular shape, and increase the rate of egg breakage.

- Among the nutrition nutrition, calcium, phosphorus and vitamin D have a greater impact on the quality of eggshells. Under normal circumstances, the calcium requirement in the diet of laying hens should be 2.7-3.75%, which is 3-4 times larger than the 0.9% calcium requirement of non-laying hens. The phosphorus content should be 0.5%. Vitamin D can promote the absorption of calcium and phosphorus. For example, in the absence of vitamin D, even if the laying hens are fed rich calcium and phosphorus, soft-shelled eggs will be produced.

- Environmental changes The temperature of the chicken house has a greater impact on the eggshell. The higher the house temperature, the more damage the eggs will be. In summer, the eggshells of eggs laid by chickens are usually about 5% thinner than eggs in other seasons. This is mainly because high temperature will reduce the chicken's feed intake and the corresponding decrease in calcium intake. In addition, in a high-temperature environment, if the relative humidity is high, the heat dissipation of the chicken is not good, and the egg will be damaged even more.

- the sense of responsibility of the management staff. This is a major factor. When picking up eggs, placing eggs, moving egg boxes, and weighing, whether they are handled with care and handling has a great impact on the breakage rate of eggs. Daily management. Excessive rearing density, delayed egg picking, few laying boxes, and too little bedding will increase the breakage rate of eggs. Improper vaccination. Such as vaccination during the laying period, due to immune response, within a few days after vaccination. In addition to the drop in egg production, the breakage rate of eggs will also increase.

- The type of battery layer cages. Due to the difference in the arrangement of the cage and the passage of the eggs through the egg trough, the damage rate will also be different. Generally, the damage rate of a single-layer cage is higher than that of a multi-layer cage. The reason is that two rows of cages share one egg trough and egg trough. It is located under the material trough, and it is not easy to find and repair in time once a failure occurs. The iron wire of the bottom net of the cage is too thick, the elasticity is poor, the inclination is not enough, or the egg trough of the lower cage is often subjected to collision, deformation, bending, pressure welding, broken ends, the egg collection belt is skewed, and there is no egg protection under the front net of the cage. The eggs in the upper cage or the upper cage are pecked by the chickens in the lower cage, especially the ladder type, which often increases the breakage rate of the eggs.

Why should we standardize the use of automatic breeding equipment

%AM, %28 %401 %2021 %08:%DecWhy should we standardize the use of automatic breeding equipment? Now automatic breeding equipment emerges endlessly. Use automatic chicken raising equipment to raise laying hens to improve work efficiency. Standardize the use of automatic breeding equipment to maximize the benefits. Obtain better economic benefits.

1. Imperfect disinfection system: At present, the disinfection of automatic chicken breeding equipment is an effective method to ensure the hygiene of the chicken house. Correct and reasonable disinfection can kill pathogenic microorganisms in the chicken house in time. Many farmers do not pay attention to disinfection or do not follow conventional operating procedures, resulting in poor disinfection effect and poor sanitary conditions in chicken houses.

2. Irregular vaccine operation: I believe that all farmers know that immunization is an effective way to prevent chicken infectious diseases, but many farmers are not standardized in vaccine operation or do not know the correct immunization method, which leads to the failure of chicken immunization. , This not only increased the cost, but also did not achieve good results.

3. Come and go freely: Generally, there are many farms around the farm, so many farmers lack a lot of scientific and rigorous awareness of epidemic prevention. When they return to the chicken house, they will not be disinfected by ultraviolet rays, they will enter the chicken house at will without changing disinfected clothes and shoes, and become a disease transmission vector.

4. The preventive measures of automatic chicken raising equipment are not perfect: the weather changes greatly in the four seasons, and farmers should take preventive measures against weather changes. However, many farmers did not take preventive measures when encountering sudden changes in weather or other stressors, which led to the outbreak of chickens. If the weather becomes cold, warm measures should be taken to prevent thieves from entering; if the weather is very hot, measures should be taken to cool down, and ventilation should be used to prevent heatstroke.

5. Unstable feed quality: There are many types of feeds sold in the market, so pay attention to feed prices. Changing the feed has generally reduced the diet of laying hens, diarrhea and egg production greatly reduced; broilers generally do not grow long, and the entire group will be seriously ill, so it will take more than a week to recover.

These are several issues that farmers need to regulate in the process of raising chickens with automatic chicken raising equipment. I hope the above can bring some help to farmers.

How to deworm chickens in poultry cages daily

%AM, %27 %392 %2021 %08:%DecChicken is a kind of poultry that is very susceptible to intestinal worms, whether it is free-ranged or used in poultry battery cages for raising chickens. Worms are a fairly common problem in poultry farming. Their presence will affect the growth performance of poultry, the conversion rate of feed, and the hen's egg production ability.

Poultry become infected with worms by feeding or drinking contaminated feed or water. Therefore, poultry farmers must pay attention to the hygiene of the chicken's drinking water and feed.

So how to tell if there are worms in the chicken? It can be judged from the weight of the chicken, whether there is diarrhea, and whether the feather quality is good.

When poultry farmers find that there are worms in the chicken body, they can use garlic, apple cider vinegar, pepper, etc. with the help of medicine to help the worm medicine can excrete the parasites and other internal parasites from the birds.

How to protect chickens from the harm of worms?

The main cause of poultry intestinal worm infection is their environment. Therefore, we must pay close attention to the observation of the surrounding environment.

- Keep the bottom of the cage or poultry cage where the bird lives clean and dry.

- Avoid overpopulation in confined spaces.

- Do not let your birds come into contact with wild animals.

- Provide clean and fresh food and water for the chickens.

- Make sure that new chickens are isolated for 2 weeks before entering the house or enclosure with other flocks.

Poultry equipment manufacturers share with you how to prevent chickens from being harmed by worms and some preventive measures.

The way to solve the lack of vitamin A in poultry layer cage system

%AM, %23 %387 %2021 %08:%DecThe poultry layer cage system started poultry farming and it was recognized by farmers that poultry also have a need for vitamins. It can help chickens grow healthier and is a necessary substance for the integrity of eyesight and mucous membranes.

Farmers may not notice these problems. Today, I will explain to you the main points of prevention and treatment of vitamin A deficiency. I want to be helpful to poultry farmers.

Vitamin A can especially protect the health of the mucosal epithelial cells of the respiratory tract, upper digestive tract and urinary tract. Vitamin A can be synthesized from carotene in the body.

The manifestation of vitamin deficiency: small white pustules in the nasal cavity, oral cavity, esophagus and pharynx, which can extend to the sac. Subsequently, small ulcers formed on the mucosa, surrounded by inflammatory products.

What farmers need to do: Pay attention to the coordination of feed. The diet should be supplemented with a diet rich in vitamin A and carotene. For adult hens suffering from disease, each chicken is fed a quarter spoon of cod liver oil 3 times a day. Abdominal lesions are cleaned with 3% boric acid solution once a day, and the effect is good.

Poultry farming is a meticulous work that requires careful observation of poultry by farmers. The above are the key points shared by poultry equipment manufacturers for farmers to prevent and control layer hens lacking vitamin A during the process of raising hens in poultry layer cages.

Prevention and treatment of several common diseases in poultry chicken cages

%AM, %23 %369 %2021 %07:%DecDiseases are inevitable in the process of raising eggs and broilers in poultry chicken cages. Therefore, farmers should pay attention to all preventive work and breeding work. The following is an introduction to the prevention and control measures of some serious diseases that are harmful to chickens in the process of chicken breeding.

- Egg production syndrome: Egg drop syndrome can lead to a decrease in egg production, which is easy to understand. Farmers should pay attention that this is an infectious disease, which is mainly manifested as a sudden drop in egg production or even suspension of production, discoloration of the egg shell, uneven surface or soft egg skin. In severely affected areas, chickens are best vaccinated against the disease as directed.

- Broiler ascites syndrome: There is no specific medicine for this disease. Breeders mainly take preventive measures: pay attention to the ventilation of the chicken coop, even in winter.

- Broiler Acute Death Syndrome: Use intermittent lighting in the chicken house to reduce stress.

Farmers should pay attention to the vitamin E, vitamin C, and vitamin A of each chicken in the feed 7 days before the arrival of the laying hens.

The above are the prevention and control measures and key points that the chicken cage manufacturers should pay attention to when raising eggs and broilers in the cage for the farmers to share!

The chicken house that use the poultry cage system should be disinfected

%AM, %22 %376 %2021 %08:%DecFarmers with poultry farming experience are very aware of the importance of disinfection. The chicken house using the poultry cage system must be cleaned and disinfected strictly 1 to 2 weeks before the chickens are introduced.

- Sterilize equipment. Sprayer: There are carry-on hand sprayer, carry-on motorized sprayer, stretcher-type motorized sprayer, which can be selected according to the specific situation. The disinfectant used for spraying should be prepared and dissolved before being filtered and loaded into the sprayer to prevent the residue from clogging the nozzle and affecting the disinfection work. After the sprayer is used up, it should be cleaned and maintained frequently to extend the service life. Flame blowtorch: It is a kind of industrial blowtorch that uses gasoline or kerosene as raw materials. The flame temperature is very high. It is often used to sterilize metal cages, food troughs, and drinking troughs. Don't stay for too long at a certain point during disinfection, so as not to burn the items. There must be an order in the disinfection to avoid omissions.

- Disinfection of poultry houses and battery layer cages. First, remove the feces and dirt in the poultry house. Thoroughly rinse the poultry house, poultry cages, troughs, water troughs, doors and windows with water (preferably high-pressure water), and dry the cages, troughs, and water troughs with a flame blowtorch. Flame disinfection once, and then spray disinfection with a disinfectant such as 0.5% peracetic acid or 0.5% Baidusha. Use 2%~5% caustic soda to disinfect the ground. The chicken house, work clothes, and utensils are fumigated with formalin, and 25 ml of formalin is used per cubic meter of space. 12.5 g of potassium permanganate is used. First put the potassium permanganate into the container, and then add formalin. Stir with a wooden stick. When the pungent gas is emitted, leave the chicken house immediately and close the doors and windows for at least 2 hours. Open the doors and windows 2 to 3 days before entering the chicken to allow air to flow through until there is no pungent smell in the chicken house. You can enter the chicken.

Once an epidemic occurs in chicken farms, measures should be taken quickly. First, isolate sick chickens, control the source of infection, and prevent healthy chickens from being infected, so that the disease can be extinguished within the minimum range. If there are not many sick chickens, all sick chickens should be eliminated. For chickens that are not diseased, emergency vaccination or medication should be used for emergency vaccination based on the diagnosis result.

Automated poultry equipment manufacturers here remind farmers to disinfect the chicken house frequently. Strictly control the sanitary environment of chicken house.

More...

What are the specific types of chicken cage system used for breeding?

%AM, %17 %419 %2021 %09:%Dec

The chicken cage system of the basic facilities for breeding laying hens is as follows:

- Chicken housefor poultryequipment. It is divided into young chick house, middle chick house, reserve house and adult house.

- Disinfection facilities for poultry equipment. There is a disinfection tank at the entrance of the chicken farm, and a disinfection tank for pedestrians and shoes and changing rooms at the entrance of the production area. A disinfection tank should be installed at the entrance of each chicken house.

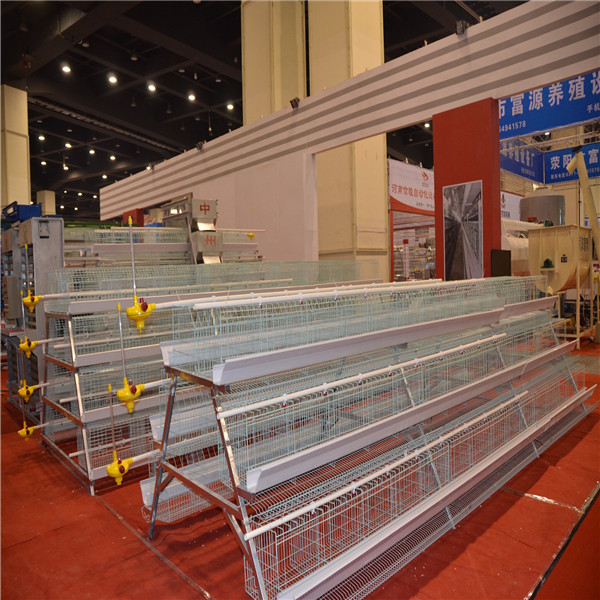

- Chicken battery cages for poultry cage system. Divided into broilercages, baby chicken cages, and layer cages.

- Feeding equipment for laying hen equipment. Feeding machinery and troughs. Feeding machinery includes chain feeders and plug-disc feeders; common troughs include long troughs and bucket-type circular troughs.

- Drinking equipment for laying hens. There are trough drinkers, tower vacuum drinkers, nipple drinkers and other types.

- The laying hen equipment should also have manure cleaning equipment, heating equipment, lighting equipment, ventilation equipment, etc., which can be selected according to the actual situation of each site.

- There are fixed chicken manure storage and stacking facilities and places for the manure treatment of laying hen equipment, and measures for preventing rain, manure liquid leakage and overflow in the storage field.

- Anti-epidemic medical equipment for laying hen equipment.

The equipment for raising chickens generally includes three aspects: heat preservation equipment, breeding equipment and lighting facilities.

The heat preservation equipment includes: stove, heat preservation umbrella, infrared lamp.

Feeding equipment includes: pans, buckets and drinking fountains. The feeder pan is used when the chicks are 1-8 days old, and one is provided for every 80-100 chickens; after 9 days of age, they will be gradually replaced with a feeder. The diameter of the suspended feeder is 38 cm, every 100 Feather chickens need 3 suspended buckets.

There are two types of automatic poultry drinking system: portable and hanging. 1-8 days old chicks use portable drinking fountains with a capacity of 0.5 kg.

70-80 chickens need one; after 9 days of age, replace a larger medium-sized waterer with a capacity of 2 kg, one for every 70-80 chickens; if a hanging automatic waterer is used, one for every 125 chickens ; If water is supplied from an automatic drinking trough, each chicken should occupy 2 cm of drinking water.

Lighting facilities: Install a lamp holder with a lampshade every 20 square meters, and prepare a 40W and 15W bulb for each lamp holder. Use 40W bulbs for 1-6 days of age, and 15W bulbs after 7 days of age.

Enclosure: In the early stage of brooding (1-7 days old), in order to prevent the chickens from getting cold away from the heat source, a thick cardboard or mat can be used around the insulation umbrella. The height of the retaining ring is 15 cm, and the distance from the edge of the insulation umbrella is 70-150 cm. The enclosure gradually expanded from the 3rd day and can be removed on the 7th day.

Deciphering the key points of broiler cage breeding technology

%AM, %16 %398 %2021 %08:%DecWhen farmers use broiler cages to raise chickens. To master some technical key points of chicken coops and cages is the problem of breeding good broilers. Therefore, broiler cage manufacturers have come to explain the key technical points of broiler cages for farmers.

1. Check the light: the light is required to be soft and bright, which can reach all parts, and there should be no dark corners.

2. Check the water line: make sure that the pipe does not leak or seep water, and that each nipple is in good condition to ensure water supply

3. Check the electrical wiring: all electrical wiring must be carefully inspected to prevent leakage wiring. There are more metals in the caged chicken house. Once the leakage occurs, the consequences will be disastrous.

4. Temperature test: check whether the boiler, radiator, temperature control computer and water pipeline are in good condition, and place the temperature control probe on the level line of the second layer of chicken back. Then close the skylight and all vents, and the ignition will heat up. Observe how long it takes for the room temperature to reach 30 degrees, and place precise temperatures on the left, right, front, back, middle, upper, middle, and lower floors according to the structure and layout of the shed.

Meter, hygrometer, check the actual temperature and humidity of each part, how far is the difference from the temperature control computer, be aware of and keep a record.

5. Disinfection: Close the chicken house one week in advance for fumigation and disinfection for 24-48 hours. After ventilating for 2-3 days, spray and disinfect. The disinfectant should be a product that is not corrosive to metal.

6. Check the cages: make sure that each cage door can be opened and closed freely, and that the bottom and four walls of each cage are well sealed with a bottom net to prevent the chicks from getting out of the cage.