Do you need to seal the chicken house when using poultry battery cages?

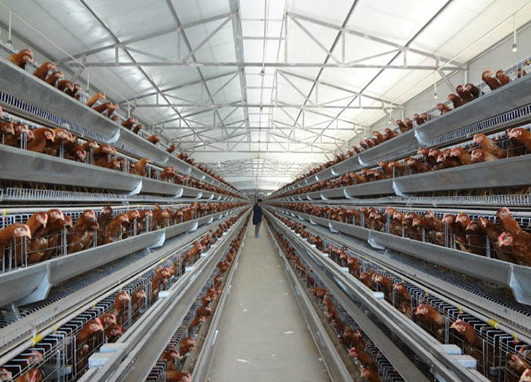

%AM, %15 %448 %2021 %09:%DecUp to now, poultry battery cages have been widely used in poultry farms. Many poultry farmers will wonder what kind of chicken house can better use battery chicken cages?

In fact, whether it is a closed or semi-closed search is possible.

The prerequisite for effective ventilation is that the battery chicken cages of the chicken house must maintain good airtightness, allowing fresh air to enter the chicken house from the side wall vents or the water curtain at the front of the chicken house. Therefore, it is required to check and test the tightness of each stacked chicken cage in the field. The pressure in the house can be tested using the AC2000 system, that is, all air inlets in the house are closed, only one fan is turned on, and the static pressure in the house is checked. Compared with the standard, if the static pressure in the house is within the standard range, it means that the chicken cages are better closed. The lower the static pressure in the cage, the worse the airtightness of the chicken house.

For chicken houses with poor airtightness, look for places with serious air leakage to add blockages, especially the front and rear doors, manure baffles and water curtains of the chicken houses. In addition, the longitudinal ventilation system is mainly used during the high temperature period, and the wet curtain cooling system is used.

Semi-enclosed chicken houses do not have high requirements for automatic poultry farming equipment in the chicken houses. Farmers can simply use poultry battery cages for breeding, which is very simple and convenient.

The above is what kind of house is suitable for poultry stacking cages. After reading this article, I believe everyone has the answer in their minds. In fact, poultry cages can be used in both enclosed and semi-enclosed chicken houses, and the area of the chicken house can be used optimally.

Main points of epidemic prevention of poultry farming equipment in chicken house

%AM, %09 %429 %2021 %09:%DecModern poultry farming equipment greatly reduces labor intensity and labor costs, and can better control the environment of the chicken house, but the control of chicken disease prevention is still the focus of farmers that cannot be ignored. Here is an introduction to the key points of chicken disease prevention and control for farmers.

The first is that the feed should be fresh, try to feed the feed within one month of purchase. Breeders should be reminded not to store a large amount of feed as much as possible. Not only is it not fresh, but it is prone to spoilage if it is not well preserved, which will cause the chickens to get sick.

Clean up the feces promptly. Farmers can use automatic manure removal equipment to clean the chicken manure every day, and will not allow the ammonia in the chicken house to exceed the standard. Ammonia is a harmful gas that can seriously affect the health of the chickens.

Strengthen immunity. In order to prevent the chickens from getting sick, it is very necessary to immunize the chickens. At present, the effective way to prevent infectious diseases is to immunize chickens. Therefore, farmers must do a good job of immunization during the process of raising chickens, and formulate reasonable immunizations according to the disease epidemic situation in the area and the actual situation of the chicken house. Procedures and immunization methods are also the key points of how to prevent diseases in chickens.

Control the temperature and ventilation: When ventilating and controlling the temperature of the chicken house, farmers should follow the principle of “as far as possible to ensure the temperature under the premise of ensuring normal ventilation”. In addition, there is also the humidity in the chicken house. Pay attention to the balance between temperature and humidity under high temperature and low temperature; when the temperature is high and the humidity is high, it is easy to form a sultry environment, which will have obvious adverse effects on the growth and health of the chicken.

The above is the specific measures for disease prevention and control shared by the battery cage system manufacturers. It is hoped that farmers can practice the above methods to reduce the possibility of chicken diseases.

How do poultry cages raise chickens in poultry farming?

%AM, %06 %508 %2021 %11:%Dec

With the rapid development of chicken farming equipment automation, the poultry cages breeding model has been recognized by the majority of poultry farmers. This kind of breeding method has the advantages of high space utilization, and efficient treatment of chicken manure to reduce environmental pollution. Reduce labor intensity and improve production efficiency.

Poultry cages have many functions in the breeding process, but the premise is to know how to use and manage them rationally.

The advantages of using poultry battery chicken cages

- The automatic drinking water system can ensure equal pressure in the water pipe and ensure the drinking water for the laying hens.

- Chickens can get more breeding area to increase the laying rate of laying hens.

- The design of lengthening the edge of the trough reduces the waste of feed and improves the effective conversion rate of feed.

- Convenient disinfection, easy to control coccidiosis and other worm diseases and worms.

- The ventilation effect is good to ensure that the laying hens in the cage system will not suffocate due to high temperature.

- Automatic egg collection system and layer cage design can improve the cleaning rate of eggs.

- The use of the manure removal belt imported from Italy can ensure the cleanliness of the cage system, layer cages, reduce the breeding of germs, and reduce the disease rate and rate of laying hens.

- Convenient maintenance and repair.

Nursing measures of layer battery cage breeding before laying hens

%AM, %01 %387 %2021 %08:%DecRaising laying hens in layer battery cages is very convenient for farmers, because there is no need to hire personnel to pick up eggs, and there is no need to worry about egg breakage.

- Regular epidemic prevention

Before the chickens lay eggs, all epidemic prevention should be done in an all-round way. The epidemic prevention time should be carried out separately for different diseases, and it must not be done at one time with ease. This is not only stressful to the flock, but also affects the normal absorption of the vaccine. Chicken farmers in rural areas should pay attention to it, arrange immunization time reasonably.

- Check the chicken cages

If the chickens are basketed before the start of labor, the cages should be carefully inspected, thoroughly disinfected, and damaged or deformed parts should be repaired in time to prevent egg breakage. According to actual production findings, the egg breakage rate due to chicken cages has always been high.

- Adjust the ration

Before and after the age of 110 days, if the growth and development of the chicken meet the standard, the feed can be adjusted and changed in time to meet the egg production needs of the chicken group. It can be directly changed to the egg-laying material, and the full-price layer material is fed to 5% of the egg-laying period, so as to provide the nutritional reserves of the eggs in the flock.

- Increase light

As the chickens start to produce, the light should be gradually increased. It is advisable for the chickens to lay eggs up to 17 hours at the peak.

The above is the management of laying hens before laying eggs, which are shared by automatic poultry equipment manufacturers for farmers. Farmers can take the above measures to manage the laying hens, so that the laying hens and better egg production.

Automatic poultry farming equipment helps farmers get rid of artificial water feeding

%AM, %29 %414 %2021 %08:%NovMany farmers are still suffering from artificial water feeding. Artificial water feeding is a very troublesome thing, but the good thing is that there is a solution if there is trouble. The automatic water diversion system in the automatic poultry farming equipment is specially designed for the drinking water of chickens. Here is a brief introduction for farmers.

The appearance of the automatic poultry drinking water equipment in the automatic chicken breeding equipment is a long water tank with an opening on it. The water tank is equipped with a fence. Chickens can stand on both sides and drink water from the opening to prevent chickens from directly standing on the water tank and polluting the water source.

There is an automatic water inlet valve on one side of the automatic drinking fountain. The slender hose can realize automatic water supply. When the water reaches the specified water level, the valve will automatically close. When the water level drops to a certain level, it can automatically enter the water. The length of the drinking fountain is about two meters and the diameter is about 110mm. It is suitable for chickens over fifteen days old. It has a good effect on liberating manpower and improving the production efficiency of the chicken farm.

The above is a brief introduction to the automatic poultry water supply system. Poultry cage manufacturers believe that the emergence and use of automatic drinking fountains in automatic chicken farming equipment can help chicken farmers realize automatic water supply, which is a rare help for farmers good equipment to reduce workload.

Chicken farming equipment manufacturers explain how to protect the digestive system of chickens

%AM, %29 %396 %2021 %08:%NovFor the breeding work, it is necessary to ensure that the diet is good. Nowadays, most of the breeding is carried out in cages, which reduces the amount of activity of the chickens and causes the symptoms of indigestion, which will cause the digestive tract of the chickens in the long term. Great influence, today the chicken farming equipment manufacturers explain the methods to protect the digestive system of chickens.

1. Prevent the raw material from becoming moldy

Farmers can add deenzyme preparations to the feed to reduce the harm of mycotoxins in the feed; farmers also need to regularly check the water quality of the chickens to prevent harmful bacteria such as E. coli from exceeding the standard, and reduce the incidence of intestinal diseases.

2. Reduce environmental stress

The fluctuating high and low temperature in the chicken house, changes in weather and seasons, or the intensity of light and changes in time will cause stress to the flock, leading to non-pathological diarrhea in the flock. Here, the breeding equipment manufacturers need to remind the farmers that the chickens are timid due to the nature of the chickens. They must not only prevent the mutation of the environment in the chicken house, but also prevent the external environment from stressing the chickens.

3. Mix the ingredients evenly when mixing

During the brooding stage of the flock, it is necessary to ensure that the feed is balanced, easy to digest and absorb pellets; and in the feed transition stage, attention should be paid to the gradual transition of nutrients, especially the transition of stone powder between the preparatory period to the peak period of laying and the arrival of young chickens. Soybean meal transition between due dates.

4. Prevention and control of coccidiosis and bacterial enteritis during the brooding period

Coccidiosis medicine can be administered to chicks after 15 days of age. If symptoms of small intestinal coccidiosis and caecal coccidiosis occur, in order to prevent mixed infection with necrotizing enteritis or secondary necrotizing enteritis, coccidiosis and intestinal medicine must be taken at the same time use. If symptoms of viral diarrhea occur, intestinal drugs must be administered at the same time as antiviral drugs.

The above is the health care measures of chicken digestive tract explained by the chicken raising equipment. We should all pay attention to it.

The positive role of automatic poultry equipment in chicken farming project

%AM, %25 %424 %2021 %09:%NovMany farmers have already felt the advantages of automatic poultry farming equipment in their farms. They not only realized intensive breeding to make it easier for farmers, but also promoted the upgrading and optimization of the entire breeding industry. Therefore, the positive effect of poultry farming equipment is very trustworthy.

The complete set of automatic poultry farming equipment includes chicken cage system, automatic egg collection system, automatic water supply equipment, automatic manure removal equipment, automatic feeding equipment, automatic ventilation equipment, etc. They are used in conjunction to help farmers better develop their chicken business.

Farmers can choose the above equipment according to their specific needs on the farm. Different automation equipment has different effects on farms, and farmers need to purchase them reasonably.

With the use of automatic poultry equipment, automatic feeding, drinking, egg collection, and cleaning of chicken manure can be realized. Farmers no longer need to hire personnel to do these tasks, which not only improves the efficiency of breeding, but also reduces the expenditure of farmers.

The above is the positive role that the poultry equipment manufacturers share for the farmers to use poultry breeding equipment in the chicken farm.

Four Attentions to the Temperature Control of Broiler Breeding Equipment in Cage

%AM, %23 %405 %2021 %08:%NovBroiler cages are simple to talk about, and there are many details in the operation, especially the temperature control of the chicken houses throughout the year, which makes it difficult for farmers to grasp. Today, the broiler cage manufacturer will introduce you in detail.

1. The thermometer is placed reasonably (height and number). In standardized chicken house breeding, the length and width of the chicken house are relatively large, and the temperature in the east, west, or north and south of the chicken house is inconsistent. Attention should be paid to the reasonable placement of thermometers. Get the average temperature in the chicken house.

2, summer cooling measures (wet curtain). In summer, a wet curtain can be used to reduce the temperature in the chicken house. At the same time, attention should be paid to the opening time of the wet curtain to prevent the temperature in the chicken house from being too low or the temperature in the chicken house inconsistent, causing chickens to catch a cold.

3. Temperature control in autumn. In autumn, the temperature difference between day and night is large, and the temperature in the chicken house should be adjusted to avoid the phenomenon of high and low temperature.

4, keep warm in winter. In winter, use heating or blowers to increase the temperature in the chicken house.

More...

Poultry equipment manufacturers help farmers reduce feed waste

%AM, %23 %306 %2021 %06:%NovDuring the investigation, it was found that many farmers have a headache on how to reduce the waste of feed when raising chickens, because feed waste will account for almost 60% to 70% of the cost of raising chickens. Is there any feasible way to reduce the cost of feed?

Poultry equipment manufactures believe that in order to reduce the production cost of raising chickens and increase the economic benefits of raising chickens, farmers must increase revenue and reduce expenditure, that is, find low-cost feed products of the same quality while reducing feed consumption and waste.

For low-priced feed products, farmers need to do relevant market research when purchasing, reduce the purchase price of feed, save production costs, and appropriately shorten the transportation distance of the feed, because the transportation cost is also in the price of the feed itself.

In order to reduce feed consumption and waste, farmers need to reduce the water content of the feed itself when purchasing to ensure that the nutrients in the feed will not decrease with the increase in water content. Good feeding methods should also be adopted and automatic poultry farming equipment should be used. Energy-saving trough in the middle, reduce the waste of feed.

The above are the ways and methods that poultry farmers can implement to reduce feed waste. In addition, farmers can choose to use the automatic poultry feeding system of automatic poultry breeding equipment, which can provide feed to the chickens in a timely manner and reduce waste.

What are the important functions of automatic poultry farming equipment?

%AM, %20 %172 %2021 %03:%NovMany farmers are now using automatic poultry farming equipment to develop the poultry farming industry. Although some people have poultry equipment that increases the input cost of the farm to a certain extent, they must know that their advantages in the farm are very obvious. The income of farmers, the improvement of the environment of the farm, etc.

Poultry equipment is now a very complete automation system. The poultry system can realize automatic feeding, water supply, manure cleaning, ventilation, etc., which not only provides a comfortable and quiet living environment for chickens, but also improves the productivity of the chicken house and increases the income of farmers.

With the use of these equipment, farmers do not have to spend all day in the chicken house to feed the chickens, supply water to the chickens, clean up chicken manure, pick up eggs and other things. The automatic chicken cage system will complete all these tasks. Farmers only need to observe the status of the chickens every day.

The role of chicken raising equipment in modern poultry production value farms is very obvious and beneficial. They have been used by many farmers and received wide acclaim.

The above is the role of poultry farming equipment in poultry farms, hoping to help farmers to learn more about the automatic chicken farming equipment.