Introduction of raising method of chicken farming equipment

%AM, %14 %460 %2022 %10:%JunWith the development of aquaculture, chicken equipment has been widely used. The equipment provides battery cage system, ventilation equipment, water supply equipment, feeding equipment, egg collection equipment, excrement cleaning equipment and other functions. Save manpower, convenient and fast. What is the feeding method of this equipment? Poultry equipment manufacturers are briefly introduced.

First, the horizontal raising of commercial broilers

Flat feeding is to put chickens into the chicken house chicken raising equipment, also known as free range. The advantages of flat chicken are simple mechanical equipment, large space for activity, good growth and development, less investment in the construction of breeding farms, less or without full price feed. Flat rearing is divided into cushion flat rearing, net flat rearing and half net flat rearing.

(1) Flat feeding of cushion materials

Suitable for dry climate area, chicken farming equipment for raising chicken, chicken, broiler or breeding chicken. Hen house with cement floor, in the hen house on the ground placed grass shell, sand, broken stems or sawdust and other matting. Chicks live in beds, but they usually don't know. After a feeding cycle, the bedding is removed along with the chicken manure. This method of raising less investment, fast construction, less equipment, but crow and feces direct contact, prone to infection of chicken disease, need more bedding and labor. In recent years, this method of financing has dwindled.

(2) Online flat rearing

Galvanized nets, strips of wood or bamboo are placed inside the chicken 60 cm above the ground to form a grid bed, where the chicken lives on the net. Chicken manure falls to the ground through a net or grating and can be periodically cleaned manually or mechanically. It is suitable for raising chickens and broilers, but the bars and metal are easily corroded, so it is difficult to observe the living conditions of chickens. Advantages: reduce chicken and excrement contact, chicken bed dry health.

(3) The equipment used for flat rearing varies with the growth stage of the chicken and the way in which the equipment is raised. Drinking equipment can choose long trough type drinking water or hanging tower type drinking water.

Chicken facilities rely on natural airflow through Windows for ventilation and natural light. Temperature and humidity basically change with the climate of the four seasons. Equipment investment is small, feed requirements are not strict. Through the introduction of the above chicken farming equipment feeding method, I hope to help you.

Considerations for selecting and installing battery cage systems

%AM, %13 %450 %2022 %09:%JunNo matter raise chicken in small quantity or scale raise chicken to want to do early preparation work. The chicken farming equipment is very important. Only complete and perfect equipment can make chickens have a very comfortable growing environment. Only in this way can the chicken grow healthily. Poultry farming equipment is based on the needs of the design of a complete variety of chicken. So how to choose and install for chicken farm?

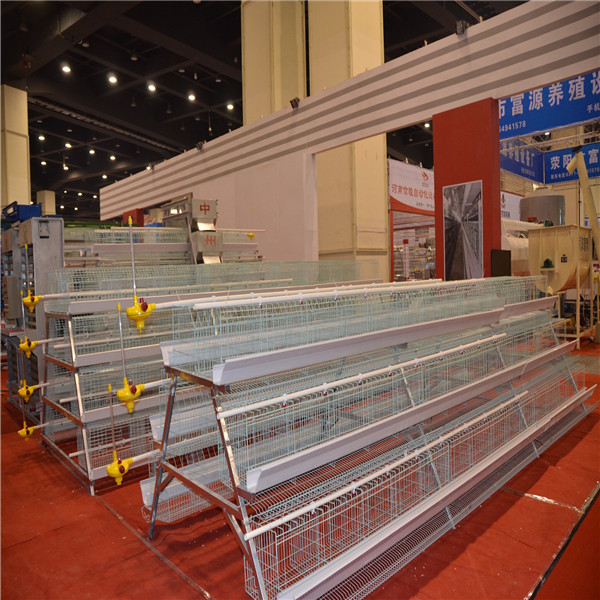

Battery chicken cages for sale in South Africa are a must for chicken farms. A good coop provides a comfortable living space for chickens. But the selection process of the chicken coop to fully consider its matching chicken equipment. Such as feeding equipment, drinking water equipment, dung cleaning equipment.

Chicken farming equipment is a chain drive seeding feeder to feed the machine, so we need to pay attention to the following points when we install:

- Half an hour before starting the breeding equipment, some vitamin C can be added by drinking water to reduce the probability of stress.

- The traction host of the dung cleaning mechanism should be installed outdoors. The height of its installation platform needs to be basically consistent with the horizontal position of the bottom of the dung tank.

- The depth of manure tank of breeding equipment is required to be above 30cm, the two walls and the bottom of the manure tank are required to be relatively straight, and there are no other obstacles in the manure canal.

- the host and corner can be installed fixed parts need to be embedded, and the installation needs to be firm.

Poultry equipment needs to be installed in strict accordance with safety operation procedures to ensure the normal operation of equipment.

How do chickens living in battery cage systems get the best water intake?

%AM, %10 %523 %2022 %11:%JunNow the battery cage system in Ghana is the most common way of poultry farming. Chickens can be well cared for in chicken coops, and automatic drinking water, feeding, manure cleaning, environmental control, etc. can be realized, so chickens living in poultry chicken cages for sale can get the best water intake.

The water consumption of chickens will be related to battery cage system, water consumption and season. The following is an introduction to the optimal water intake of chickens in different periods and conditions for poultry farmers.

- Increasing age: 1-6 weeks old chicks, 20-100 ml per chick per day; 7-12 weeks; young hens, 100-200 ml per hen per day; 200-230 ml per hen for poor hens; laying hens 230 to 300 ml.

- The ratio of water consumption to input power: under normal temperature (20°C), the amount of water added is 2 times; under high temperature environment (35°C), the amount of water added is 5 times.

- The amount of drinking water increases with the increase of egg production rate: the egg production rate is 50%, and the daily water required by laying hens is 170ml; after the egg production rate increases by 10%, the water consumption increases correspondingly by 12ml.

- Seasonal changes in water intake: 100 ml per chicken per day in winter, 200 ml per chicken per day in spring and autumn; 300 ml per chicken per day in summer.

The above is the chicken farming information shared by chicken farm equipment manufacturers for you. The use of battery cages systems has been proven to give chickens optimal water intake. Please feel free to use it for farmers who use chicken raising equipment.

How to start poultry farming in Kenya?

%AM, %08 %469 %2022 %10:%JunPoultry farming business is one of the most important and lucrative aspects of livestock farming business, especially in Kenya and Nigeria. But like every other business, there are risks and challenges. Are you planning to get into poultry farming but want to know the risks and challenges you will face?

The current state of poultry farming.

- Supply and demand side: There is a serious imbalance between supply and demand. Social demand is higher than supply.

- Production side: backward equipment, low efficiency, high labor intensity, and great pressure on environmental protection.

- Sales side: The sales channels for live poultry are shrinking rapidly, and there is nowhere to sell live poultry.

What do I need to prepare to start raising chickens in Kenya?

- There is enough land to build a chicken farm. If you plan to raise 10,000 chickens, in the case of using battery cage system in Kenya. Requires 500 square meters of land.

- quotation of poultry farming equipment in kenya. Intensive chicken farming using automated poultry equipment is now very well received. It can realize automatic drinking water, feeding, manure cleaning, egg collection, ventilation, etc. Poultry farmers save worry and effort.

- Have sufficient funds. Starting a poultry farm is not an easy project. Need to buy a lot of things.

It is suggested that the poultry industry will still have good development in the following points in the future:

- Strengthen industry confidence and expand industry market space.

- Grasp the pace of development, avoid the crisis of overcapacity, and prepare for a protracted war.

- Accelerate transformation and upgrading to create new advantages for future development;

Chicken farm equipment factory should pay more attention to the strengthening of brand building to better enhance the added value of products.

Correct methods to reduce the rate of broken eggs

%AM, %02 %434 %2022 %09:%JunAt present, the problem of broken eggs in domestic chicken farms brings larger losses to farmers. The daily rate of broken eggs is now around 18 percent of the daily output. This is a very high number. How to avoid such a situation? Next poultry equipment manufacturers will explain to you how to avoid egg breakage.

1.Increase the number of egg collection every day. Try to use automatic chicken equipment to collect eggs. Special attention is needed during peak egg production. Don't overdo it so as not to startle the chickens. Use the egg picker to collect the eggs after the movement should also be light.

2. flat chickens to ensure that the egg box is enough. Soft cushions should be laid at the bottom of the container, and cushioning pads should be used on the inside of the egg tank to cushion the impact.

3.Insist on checking the health status of chickens to prevent the occurrence of various diseases. Because there are a lot of diseases that not only cause the drop but the egg production plummets. It also makes the eggshell thinner. Directly leading to an increase in broken eggs.

4.breeding statistics of higher eggshell quality belongs to brown shell laying hens. The rate of shell breakage of brown eggs is generally lower than that of white eggs.

5, try to use automatic chicken raising equipment for feeding operation. Eliminate miscellaneous people to enter the chicken farm. Create a quiet and comfortable environment for chickens to grow and lay eggs.

6.From 48 to 58 weeks of age, a short hunger strike of 3 to 6 days is required. During this period, egg production will not be affected, and the rate of broken eggs can be greatly reduced.

The above is the poultry equipment manufacturers from 6 points to share the use of poultry equipment equipment in Soulth Africa to reduce egg breakage rate. Here is a sincere proposal for poultry farmers to use poultry cage chicken. If you are interested, please leave a message.

How to start an intensive poultry farm?

%AM, %01 %441 %2022 %09:%JunAre you planning to start your own poultry farm? If so, then you should be well prepared by considering all its aspects. For example, understand the battery cage system price from poultry equipment manufacturers.

The demand for poultry products is increasing every day. So with intensive farming, as long as you follow some chicken raising knowledge, your poultry farm still has a lot of room for rapid growth despite the competition. And using a poultry coop system will make a quick return on your investment.

Wondering how to start a chicken farm? Poultry equipment manufacturers have some great guidelines here. Follow these rules for a successful poultry business.

Choose your poultry species

Poultry farming is a broad industry. The most widespread are layers (egg production) and broilers (for chicken). The cascading chicken cage is the choice of most poultry farmers now.

At present, poultry equipment mainly includes chicken battery cages, automatic drinking water, manure cleaning, feeding, egg collection, and environmental control system. Poultry farmers can choose. With poultry equipment, intensive farming can be achieved. Manage 30,000 birds easily with 2 people

Select the poultry farm address

Choosing a good farm location for your business is very important. You should choose a location that has all the required amenities and is beneficial to your business. It may be a little further out of town, where land and labor are fairly cheap.

But don't set the farm too far from the town. Because most towns have high population densities, you have to target that market. Also try to avoid setting up farms in residential areas, as poultry farms can produce unpleasant odors. When choosing a farm location, also consider transportation systems and medication facilities.

Please choose a reliable poultry equipment manufacturer. Purchase a quality battery chicken cage system. High-quality chicken cage equipment uses hot-dip galvanized material, which is strong and durable. Can be used for 15-20 years. Poultry farmers do not have to worry about changing the battery cage system during the breeding period.

What is the solution to producing thin century eggs

%AM, %31 %441 %2022 %09:%MayConstitute the egg shell thin elements of many, for example, nutrients, varieties, management and so on. In addition, the selection of automatic chicken raising equipment, temperature and ventilation are the main factors affecting eggshell thinness.

The temperature. Too high or too low a temperature in the hen house can affect egg shell quality. The reason is that temperature affects feeding and feed intake affects nutrient content.

Buy a premium battery cage system. Quality - assured automated chicken raising facilities allow chickens to be taken good care of. Provide a good living environment.

Usually when the temperature is higher than 32℃. Chicken body heat is difficult, appetite is reduced, intake cut. Prolonged high temperatures can damage the nutrient balance of the chicken. Cause metabolic changes, so that the thyroid function of chickens reduced, resulting in lack of calcium in the chicken body. Easy to produce thin shell or soft shell eggs.

When the temperature drops below -12℃, the feed intake of chickens decreases and the eggshells become thinner. Therefore, it is cool in summer and warm in winter, so that the temperature in the chicken house should be kept between 15℃ and 25℃ as far as possible, and the concentration of energy, protein and minerals in the diet of laying hens should be adjusted according to the season to improve the laying rate and eggshell quality.

Ventilation. The effect of ventilation on the eggshell is affected by the concentration of harmful gases. When the chicken house is poorly ventilated, the concentration of ammonia gas is too high, it is easy to cause respiratory ammonia poisoning, so that the chicken body loses more carbon dioxide, resulting in the lack of carbonate ions that constitute calcium carbonate, affecting the absorption of calcium, thus resulting in the production of thin shell eggs. Therefore, automatic chicken equipment is often used in the chicken house for ventilation, timely cleaning of feces, to avoid too high ammonia concentration.

These are the four tips poultry equipment manufacturers shared to solve the problem. Let's hope poultry farmers don't panic when it comes to thin-skinned eggs and find a solution.

Poultry equipment suppliers teaches you to raise chickens scientifically

%AM, %30 %442 %2022 %09:%MayFarmers should pay attention to employees' familiarity with, operation and management of automated chicken raising equipment. Avoid irregularities and errors in operation. Regular training should be done.

Do a good job of chicken farm immunity

Immunization is an effective means to prevent infectious diseases in aquaculture. It is the work that raisers must take seriously and must do. Farmers only according to the actual situation of the chicken farm to develop a good reasonable immunization procedures and methods, the correct implementation, to avoid immune failure.

To manage well

Now most of the farms are automated chicken raising equipment scale, intensive breeding mode. Then pay attention to management in the process of breeding. Only with good management and coordination of all aspects can there be fewer and no problems in implementation.

Standardized drug use should be done well

Standardized and scientific drug use. Eliminate drug residue and implement food safety. Farmers' flocks are also more welcome to the market. It can also ensure that farmers can have a good income in the process of breeding.

The above is poultry equipment manufacturers from good staff management, do a good job of chicken farm immunity, do a good job of management, standardized drug use four aspects. Scientific chicken breeding for better development of poultry farming programs.

More...

How does the automatic poultry feeding system work?

%AM, %27 %435 %2022 %09:%MayAutomatic poultry feeding system is a kind of equipment in chicken raising equipment, which is very common in large and medium-sized farms. Not only save time, but also reduce the labor force of breeding personnel. Do not need a lot of personnel, only need to operate the equipment, you can realize the equipment automatic feeding system.

1, The frame is made of good rectangular steel welded, with large bearing capacity and no deformation of the structure.

2, The walking power system is driven by advanced cycloid gear reducer, drive without loss. Low failure rate, and smooth operation, improve the efficiency of egg production.

3,The walking system adopts chain and sprocket drive, and the guide rail is laid with square steel, so that the walking is stable and the contact area is increased.

4,The blanking system of automatic feeding machine of chicken raising equipment adopts the design of core technology and is equipped with a homogenizer to ensure uniform blanking

5, the power distribution system is chint electric appliances, using limit switch, automatic stop at the end of the walk. We can also design various electrical control systems according to the needs of users.

6, The hoisting system of automatic feeding machine of chicken raising equipment is composed of flat conveyor and vertical conveyor. The system is controlled by photoelectric switch to improve the working efficiency.

The above division of poultry equipment manufacturers to share with you today, want to know more about chicken equipment related information, please continue to pay attention to this site.

Details of ventilation management for laying hens raised in battery cage system

%AM, %27 %427 %2022 %09:%MayVentilation is an important part of the management of laying hens in battery cage system. Proper ventilation can avoid the occurrence of many layer diseases, because ventilation is too big a concept. So here xiaobian will talk about the control of several key points of ventilation in the chicken cage.

There is no essential difference between the ventilation of laying hens' cage and that of other breeding modes. But because the cage chicken is three-dimensional farming, the same height of the chicken coop, the top chicken is closer to the roof of the shed. So in ventilation, we should pay more attention to the whereabouts of cold wind, especially the use of ventilation pipe chicken coop.

Given the circumstances. We can cover the top of the poultry cage for layer with plastic sheeting or mulch. Although not a fundamental solution to the problem, but can also play a part of the cold wind directly fell on the chicken.

Therefore, the ventilation pipe as far as possible in the early use of chicken. When the ventilation volume is large, small Windows should be used. Small window air intake can also play a role in disturbing the air intake of the ventilation pipe and promoting the mixing of the air into the ventilation pipe.

The opening of small ventilation window should be combined with the local temperature of ventilation and henhouse. It's not just that all the little Windows open the same size. For example, in the early stage of breeding, under standard negative pressure, the temperature at the back end is often low because of air leakage and faster air inlet at the near end of the exhaust fan.

At this time we have to put the small window behind appropriately close small or open one another, to achieve the purpose of temperature balance. For example, after the boiler stops using in the late stage, there is no heat source at the front of the chicken house, resulting in low temperature at the front. You can also close the front with a small window. In short, the switch of small window is not only one kind of mode, should be adjusted at any time according to the situation at any time.

The above is the poultry equipment manufacturers to share the use of battery cage system to raise laying hens ventilation problems and reasonable use.