Poultry Farming Equipment Features and Analysis

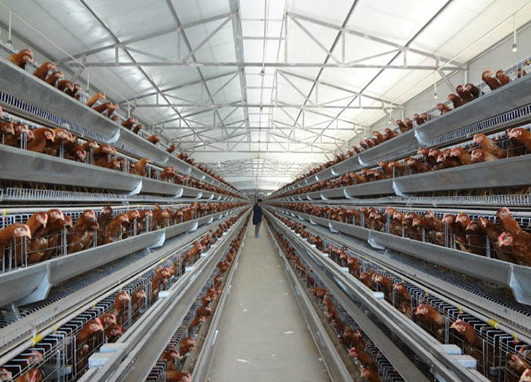

%AM, %18 %441 %2022 %09:%JulPoultry farming equipment is a special machine used by chicken farms in the production process of chicks, breeders, broilers and laying hens. Chicken farms can be divided into free-range and battery cages. Chicken raising equipment includes: layered chicken cage system, ventilation equipment, water supply equipment, feeding equipment, egg collection equipment, manure cleaning equipment, lighting equipment, etc.

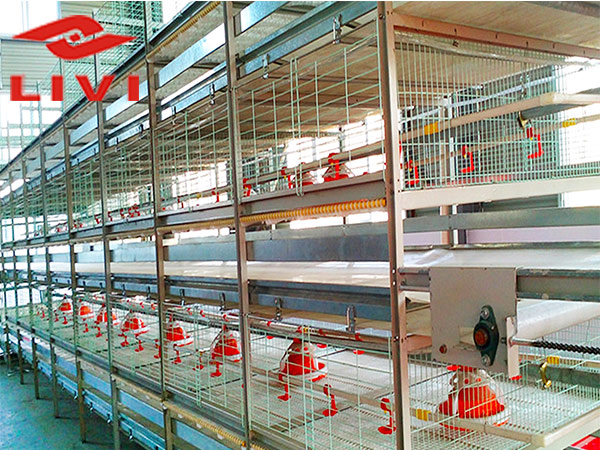

- Battery cage system. There are mainly two types of A-type chicken cages or H-type chicken cages. Farmers mostly take 60-70 days of age and transfer them directly to laying hens. Laying hens are basically raised in cages. At present, there are many manufacturers producing chicken cages, which can be purchased according to the actual situation.

- Ventilation equipment. The closed chicken house must be mechanically ventilated. According to the direction of airflow in the house, it can be divided into two types: horizontal ventilation and vertical ventilation. Lateral ventilation means that the direction of airflow in the house is perpendicular to the long axis of the house, and longitudinal ventilation refers to a ventilation method in which a large number of fans are concentrated in one place, so that the air flow in the house is parallel to the long axis of the house.

- Water supply equipment. From the point of view of saving water and preventing bacterial contamination, nipple drinkers are the most ideal water supply equipment, and high-quality water-tight drinkers must be selected.

- Feeding equipment. The feeding trough is mainly used, and the caged chickens all use long through troughs. This feeding method can also be used when brooding flat, or the hanging bucket can be used for feeding. The shape of the feeding trough has a great influence on the throwing of the feed for the chickens. The feeding trough is too shallow and there is no edge protection, which will cause a lot of feed waste.

- Poultry Manure cleaning equipment. General chicken farms use manual manure removal on a regular basis, while larger chicken farms can use mechanical manure removal.

Creating a modern chicken farm requires not only modern chicken raising equipment, but also a modern farming concept.

How to choose poultry battery cage system?

%AM, %16 %173 %2022 %03:%JulThere are many different sizes and types of battery cages on the market. How do breeders choose the most suitable cages for their chickens? This is determined by many factors.

You can choose the right battery cage based on the weight and size of your poultry and the climate in your country. For example, 1.5KG and 2.5KG require different size layer cages. In hot and cool weather, the lifespan of a laying hen of the same quality can vary greatly. There are large and small spaces, and if the area is large, you can choose A-type chicken cages or H-type chicken cages. So price is not the only consideration.

The raw materials of poultry equipment layer chicken cages are divided into cold galvanized and hot-dip galvanized. In general, hot-dip galvanizing is more corrosion resistant and lasts longer.

There are many types of chicken cages, and most of them are made of steel wire now. Generally, multi-layer chicken cages are used for raising chickens, and electric battery chicken cages are used for laying hens.

There are many types of battery chicken cages, such as three layers and four layers, etc. Batch breeding generally chooses multi-layer chicken cages.

When buying chicken cages, pay attention to the connection of the bottom net between each layer of cages. The connection should be thin and there should not be too much gap. If the gap is too large, it may cause the eggs to fall.

Prospects for the development of broiler and poultry farming projects

%AM, %15 %457 %2022 %09:%JulGlobal chicken consumption continues to grow, and it is foreseeable that broiler products will become the number one meat consumer in most countries in the near future. Along with the economic development and the continuous improvement of people's living standards, the total demand for chicken meat is also gradually increasing. Therefore, it is profitable to use battery broiler cages to develop poultry farming.

Rapid growth

Broiler chickens grow much faster than regular chickens. In general, newborn chicks can grow up to 2 kg after two months of feeding. For a broiler, it probably won't grow shag for two months. It has to be said that the growth rate of broilers is still very fast, which means that the income return of breeding broilers is fast.

Short Growth Cycle

Due to the fast growth rate of broilers, their growth cycle is naturally shorter. If nothing else, it usually takes only two months from hatching to slaughtering, and at this time, the weight of the broiler has fully reached the level of the market. After the slaughter, farmers do not need to spend a long time cleaning the chicken house, and can quickly put into the breeding of the next batch of broilers. If the breeding management goes well, five batches of broilers will be launched within a year. It's entirely possible.

High Breeding Density

Because broilers are quieter by nature, they don't like to move or fight each other. Therefore, the space utilization rate of the broiler house is relatively high. The breeding density of poultry cages for broilers is also relatively high. Therefore, the quantity of each batch of broiler chickens on the market is quite considerable. Usually, as long as the farmers do a good job of air circulation and disease prevention in the chicken house, and increase the breeding density appropriately, they can sell more broilers on the market.

How to Clean and Disinfect Poultry Farming Equipment?

%AM, %11 %453 %2022 %09:%JulWith the improvement of living standards, people's demand for chicken is also increasing. However, environmental problems in chicken cages will directly affect the growth status and production efficiency of chickens. Therefore, the chicken cage factory recommends cleaning and disinfection in the chicken cages.

1.Cleaning of poultry farming equipment prices in south africa and cages: The main design is galvanized mesh, which is not easy to scratch or pock under normal conditions, but some impurities, such as chicken feathers, feed and chicken manure, will be attached during use.

After a long time, it may scab and harden, so we need to take it out and clean it, do not wipe it with a stiff brush, soak it after washing, soak the dirt to soften it, and then rinse it with water. During the entire cleaning process, do not recommend the use of cleaning agents, because the ingredients contained in the cleaning agents will corrode the chicken cage equipment to a certain extent.

2.Disinfection of chicken cages: Chicken cages for sale maintain high density, so spray or fumigation is used for disinfection. If the disinfection is not clean, bacteria and viruses will easily remain, which is not conducive to future feeding and disease prevention. Pay attention to the rotation and amount of disinfectant when disinfecting. Before fumigation, close doors and windows, plug all gaps, and then calculate the dose of the drug based on the volume of the coop. After disinfection, open doors and windows for ventilation for 1-2 days to prepare for hatching.

The above is a relatively simple cleaning method. In fact, in order to keep the chicken cage system clean and tidy, it is necessary to carefully maintain it at ordinary times. In normal use, we try not to pull, pull and close the door hard to reduce the collision of materials. When raising chickens at ordinary times, do not sprinkle the feed around the cages, and do not soak them in liquid. Usually the correct installation method is to use it, which is an effective way to prolong the service life of chicken cage system.

How to supply the required nutrition for laying hens?

%AM, %06 %432 %2022 %09:%JulMore poultry farming friends choose to use battery layer cages to raise commercial laying hens. Feed is the only source of nutrition for poultry. So how can our poultry farmers supplement adequate nutrition for chickens during the laying period?

Commercial feed from a reliable feed store has all the nutrients that chickens need in the correct proportions. A balanced diet is necessary for optimal growth and production. If you are using a good diet that meets the flock's dietary needs, supplement with other foods that can disrupt the balance of the diet.

The daily feed consumption of chickens depends on the composition of the diet. Chickens usually adjust their feed intake to meet their energy needs. Feed intake decreases as the energy content of the diet increases, and vice versa.

Ambient temperature also plays an important role in determining how much feed a flock will consume. In hot weather, feed intake is reduced. In cold weather, chickens' feed intake increases because the chickens use more to provide the extra energy needed to maintain their body temperature.

The purpose of a laying hen diet is to optimize egg production (based on egg number, egg size or egg quality), provide the nutrients needed to support health and maintain an ideal body weight. As with laying hens, different breeders recommend different feeding strategies for their birds, including the amount of different diets fed during the laying phase. Calcium increases to form eggshells.

The above are the ways and methods shared by layer cage manufacturers to increase nutrition for laying hens in laying hen cages. I hope there is a place that can help poultry farmers.

How to effectively cool chickens ?

%AM, %04 %427 %2022 %09:%JulSummer arrives. A topic that poultry farmers have to mention is how to prevent heatstroke in summer. Every summer, chickens die from heat stroke due to high temperature. Large-scale farms have poultry farming equipment price: fans and water curtains. Cooling down is relatively simple. Today we talk about a few other ways.

- Increase ventilation

Increased ventilation can speed up the air movement inside the house. Take away the heat emitted by the chickens, thereby reducing the body temperature of the chickens. The decrease in body temperature can also greatly reduce the possibility of heat stroke. Just like we are at the same temperature and in the same environment, the feeling of wind and no wind is completely different. Therefore, in the absence of a water curtain, we should increase the ventilation volume as much as possible to reduce the body temperature of the chickens. It is recommended to use a cooling fan. It should be noted that the water supply and the fan need to be set up separately.

- Shading and cooling

For many free-range flocks, we can build shade nets in the hot summer. Or do more greenery around the chicken farm and plant some trees to block the direct sunlight, so as to achieve the effect of cooling. For the construction of the roof of the chicken coop, it is best to use white foam board at the time of construction. This can reduce the radiation of sunlight and reduce the absorption of heat.

- Change the feeding time

When feeding chickens in high temperature summer, try to avoid high temperature periods. During the high temperature period, the temperature is high. At this time, feeding increases the activity of the chickens, and the chickens are prone to heat stroke due to fighting and fighting. The feeding time can be changed to the time period when the temperature is relatively low in the morning and evening.

- Ensure water supply

In the summer heat, the temperature of the chicken house is high. Chickens live in chicken battery cages, which requires ensuring that the chickens can drink enough cool water at all times, and it is also necessary to ensure that each nipple drinker can produce water to prevent heat stroke due to lack of water. Mild water shortage will result in reduced egg production, and severe water shortage will result in a significant drop in egg production or even death from heat stroke.

How to know the price of battery cage system from poultry equipment company in Kenya?

%AM, %30 %429 %2022 %09:%JunIt is not difficult to know the price of battery cage system in Kenya. How to buy chicken cages with good quality at an affordable price is the main key. Today, poultry equipment factory elaborate on this.

Poultry farming friends buy battery cage system in Kenya. First of all, you must know the key parts of the chicken cage: cage net structure, side net structure, rolling angle, etc.

When selecting cages in poultry equipment. To observe the cage mesh. It is recommended to use hot-dip galvanized materials. Use for a long time without scratching chicken feet.

Then pay attention to observe whether the vertical angle of the cage mesh is perpendicular to the front mesh. And the gap between adjacent steel bars must be greater than 5 cm. This will not pinch the chicken head.

Here's the fuck off angle. The bottom net of the layer chicken cages is generally inclined at an angle of 7-11°. Because of the battery layer cages in Kenya. When the angle of the chicken cage is too large, the chicken will be very tired in the cage. If the angle is too small, the eggs will not roll out, increasing the egg breaking rate.

If you plan to develop poultry farming business in Kenya, as poultry equipment factory, you sincerely hope that you can choose to use the battery cage system in your chicken house. It can realize automatic drinking water, feeding, manure cleaning, egg collection, environmental control and other equipment. Not only saves labor costs, but also reduces the possibility of chickens getting sick.

Chicken house ventilation is conducive to chicken disease prevention and control

%AM, %27 %366 %2022 %07:%JunWhen using layer cages in Nigeria to raise chickens, remember to ventilate frequently. Frequently ventilating the house will circulate the air in the house and reduce the smell of the house. The most important thing is to help prevent and control chicken diseases.

The layer cage equipment must be mechanically ventilated. According to the direction of airflow in the house, there are two ways of horizontal ventilation and vertical ventilation on the chicken raising equipment.

Lateral ventilation: refers to the direction of airflow in the house perpendicular to the long axis of the house. Longitudinal ventilation: refers to a ventilation method in which a large number of fans are concentrated in one place, so that the air flow in the house is parallel to the long axis of the house.

Each group of ventilation windows of the layer cage equipment can be opened at three angles at the same time, and the ventilation is more uniform. The air inlet window close to the fan is opened smaller, and the open window away from the fan is larger to achieve uniform ventilation. The opening and closing of the air inlet window adopts plastic small wheels, which has rolling friction and low resistance. The plastic window contains anti-ultraviolet raw materials and has a longer service life. The air inlet window spring is made of stainless steel, which is strong and durable.

The ventilation device of the laying hen equipment can be automatically controlled, and the environmental controller can control the opening size of the air inlet door by pulling the motor to work according to the pressure difference set by the chicken house. In the breeding process, it is necessary to rationally use the chicken raising equipment to increase ventilation. In the weather with good sunshine and breeze, the ventilation function of the chicken raising equipment can be turned on.

Why is it recommended to buy chicken cages in Nigeria?

- Laminated breeding, the number of tiersis optional, up to 10 tiers, the breeding density per unit space is extremely high, the breeding output is large, and the benefits can be reasonably doubled.

- Automatic feeding and drinking, saving manpower, improving labor productivity, and improving the ratio of egg to material.

- Automatic egg collection to reduce labor costs.

- Conveyor-type automatic manure removal, drying and sanitation, saving labor, and manure removal can be performed several times a day, which greatly reduces the respiratory diseases of chickens.

- The feeding is centralized, reducing the mobile contact of the staff in the chicken house, which is conducive to the prevention and control of chicken diseases.

Based on all the above content, do you have a more in-depth understanding of the benefits of ventilation for laying hens? If the content we share provides you with help, you are welcome to continue to pay attention to our website, we will continue to update the newsletter information for everyone, and strive to provide services for our customers.

More...

Is it better to control house temperature with battery cage system?

%AM, %24 %424 %2022 %09:%JunHow does the chicken house control the temperature of the chicken battery cages?

Battery cage systems are commonly seen in poultry farming. In the chicken cages on the farm, with so many chickens, the temperature can easily rise.

Then we have to learn to adjust the temperature of poultry cages. We can only raise healthy chickens if we have good temperature regulation. So what should we do? Let's take a look together.

- Properly place (height and number) thermometers. The chicken house raised in the standardized chicken house is long and wide, and the temperature in the chicken house is inconsistent between east, west, north and south. You should pay attention to the proper placement of the thermometer. Get the average temperature of the house.

- Summer cooling measures (wet curtain). In summer, the temperature in the chicken house can be lowered by the wet curtain. At the same time, pay attention to the opening time of the wet curtain to avoid the temperature in the chicken house being too low or the temperature in the chicken house being inconsistent, which will cause the chicken to catch a cold.

- Autumn temperature control. In autumn, the temperature difference between day and night is large, and the temperature in the chicken house should be adjusted to avoid high temperature and low temperature.

- Insulation in winter. In winter, the temperature in the house is raised by heating or blowers.

The above points are about your body temperature. Poultry cage manufacturers recommend that the temperature of the chicken house should not be too hot or too cold, so that the vital signs of the chicks can survive better.

Common mistakes in using poultry farming equipment

%AM, %15 %420 %2022 %09:%JunNow poultry farming equipment in South Africa is widely used. But many poultry farmers do not use them correctly. Today, poultry equipment manufacturers will share the correct use of chicken equipment.

1.Do not disinfect chickens before raising them. New coop or old coop. Before entering the chick, the farmers should completely disinfect the chicken house to avoid the presence of bacterial pathogens. However, most chicken farmers are not adequately prepared for disinfection, leading to incomplete disinfection and susceptible to disease. So farmers in the chick before the complete disinfection, all aspects of equipment and tools to be disinfected.

2, do not pay attention to the choice of chicks. The source of chicken chick of partial raiser is not clear enough also. Bring about chickling health degree is unknown, raiser is choosing chickling when must buy from the breeding farm that has production management license, quality trustworthiness.

3, chicken drinking water and opening food is not reasonable. The work of feeding and drinking chicks is very important. Drinking too late can lead to dehydration and death. Too late can cause some chicks to eat other foreign bodies. Breeders should place chicks in battery chicken cages and allow them to rest in a transport box for 30 minutes. Then release free drinking water for 2-3 hours (chicks out of the shell 24-36 hours after drinking), and then spread the material on the opening plate, free to eat. Drinking water can be added with anti-epidemic drugs.

4.Improper temperature control of brood house. Chicks just born need a relatively high temperature to ensure healthy growth, farmers in the first week of just into the chick should be controlled at about 33 ~ 35℃. Because the survival rate of chicks is directly affected by temperature, too low temperature will lead to a drop in chicken body temperature, weak resistance, resulting in a variety of diseases, too high temperature will lead to heat effect, heat stroke.

5.Low awareness of health and epidemic prevention. The environmental health of the chicken farm is the key to ensure the healthy growth of chickens, so the health management of the chicken farmis very important. Poultry equipment manufacturers suggest that farmers should have special shoes and clothes when entering and leaving. Don't let people in and out of the chicken farm. If sick chicken appears, to have a sense of rapid isolation and disinfection. In disinfection, farmers must have the concept of regular disinfection.