Comprehensive and practical chicken raising technical knowledge points!

Poultry farming projects are still very popular today. How to effectively carry out poultry farming projects. The battery cage manufacturers will introduce comprehensive skills to you today.

The selection points of chicken farm site

The chicken farm site should be selected in a relatively remote living area and a place that can be reached by vehicles, a high, dry, well-drained place, and the site should have water and power sources.

The selection of chicken breeds

The selection of chicken breeds should be determined according to the adaptability and market demand of chickens in the garden. Generally, the local thoroughbred chickens with strong adaptability, strong disease resistance, strong foraging ability, rough feeding resistance, tender meat, and delicious taste are selected or hybrid chickens with more than 75% of the local native chicken blood. And to consider the market demand, choose a marketable breed, it is best to choose an excellent breed of native chickens cultivated by regular units.

From the perspective of production performance, chickens can be divided into layers, broilers, and eggs and meat. The economic benefits of broilers are high. It can be slaughtered in 45 days from rearing time. This is incomparable to other animals. Seven or eight crops can be raised within a year.

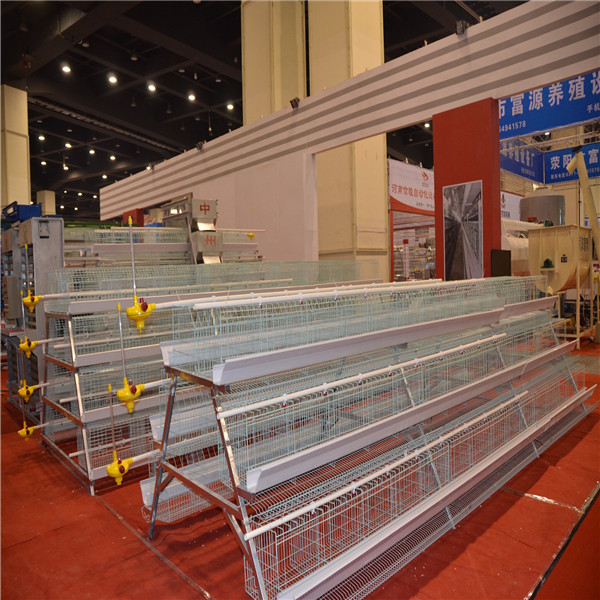

Poultry equipment needed for raising chickens

Simple chicken farms need basic poultry equipment such as chicken battery cages for sale, drinking water equipment, feeding equipment, and manure cleaning equipment. If it is a large-scale breeding, in order to improve work efficiency, more comprehensive mechanized equipment can be considered.

The problems that need to be paid attention to in the management of chicken feeding

- The management density of chicken farms should be moderate. The stocking density should be moderate. Each henin poultry laying cages should have enough troughs and drinking fountains, and the location should be appropriate. The chickens should be regularly provided clean and the water temperature should be suitable for drinking. Feeding and management of laying hens uses a chain feeder for feeding, which should be fed regularly every day, and attention should be paid to improving the nutritional level of the diet in time during the rising stage of egg production.

- To reduce the contamination of eggs, it is also necessary to minimize the contamination and damage of eggs. Environmental conditions should be as stable or gradual as possible. The closed chicken house should turn on and off the lights on time, so that the daily light time can be supplemented as required. In addition, it is necessary to adjust the ventilation volume according to the seasons to make the temperature in the house more suitable.

- Be aware of weather regulations that suddenly turn into severe weather in open houses: the impact on the flock. Feeding and management of laying hens Regardless of the type of chicken house, appropriate insulation or cooling measures should be taken to prevent cold and heatstroke, and to prevent the relative humidity and concentration of harmful gases in the house from exceeding the limit indicators, so that the chickens can maintain high and stable egg production.

How to raise chickens using chicken cages in Uganda?

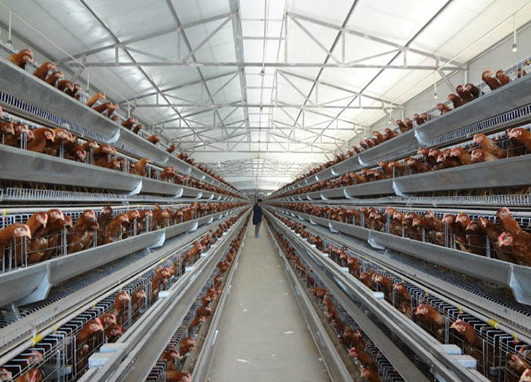

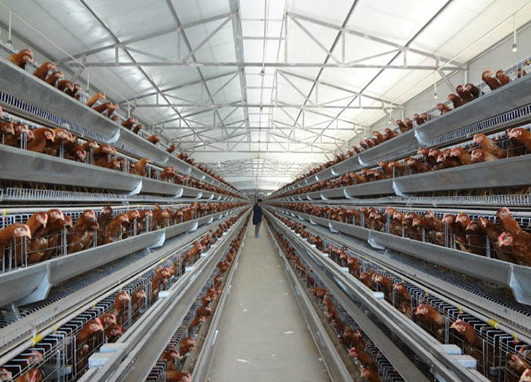

Chickens are raised using wire-welded chicken cages in Uganda. Different types of battery cages are designed according to the breed, sex and age of the chickens. There are chicken cages, brooding cages, layer battery cages, breeder cages and rooster cages, etc., which are currently the most important ways of raising chickens in the world.

Describe the advantages of battery cage system

- Improve the stocking density. The stocking density of the three-dimensional chicken cage is more than 3 times that of the horizontal stocking density. The laying hens can be raised more than 17 per square meter.

- Save the feed. Putting the chickens in thepoultrycage reduces the amount of exercise, reduces energy consumption, and reduces the waste of materials.

- Easy to install, simple to operate, strong and ventilated, suitable for open, semi-open and open houses.

- Chickens do not come into contact with feces, which is conducive to the prevention of chickens.

- The eggs are cleaner and can eliminate eggs outside the nest. 6. Compared with the ground, it saves 75% of the feeding area and improves the egg production rate.

Feeding and management methods using poultry cages for sale in Uganda

A well-managed house can save feed and avoid feed waste. And maximize the conversion of input feed into chicken growth. A well-managed chicken house will reduce the incidence of chicken diseases, which can save both the cost of vaccine purchases and the cost of routine preventive and therapeutic drugs.

Increase ventilation every day, pay attention to maintaining the humidity of the chicken house, and maintain proper humidity measures. Generally, the limit for high humidity is higher than 75%, and the limit for low humidity is lower than 40%. When the humidity is too high, ventilation should be strengthened to remove moisture. Main methods: ground spraying, aerial spraying,

How to choose chicken feed with battery cage for layer

Feed is the foundation of raising chickens and the key factor for the success or failure of raising chickens. In general, the cost of feed accounts for 70% to 80% of the cost of raising chickens. So how to choose, use and develop feed reasonably, improve the rate of return of feed, and reduce the rate of feed consumption plays a decisive role in increasing the cost of raising chickens.

Economics of raising chickens. Common feed for chicken cages can be roughly divided into energy feed, protein feed, mineral feed, vitamin feed and feed additives.

The role of poultry farming equipment in Nigeria

Poultry farming equipment in Nigeria is widely acclaimed. The utility model has the advantages of simple structure and convenient operation, which greatly saves labor. At the same time, the excrement is cleaned in a centralized manner, which solves the problem of serious environmental pollution of the whole chicken house, and has great practical value.

- Easy to manage. Now the scale of the farm is large, and the caged method is convenient for the management of laying hens and easy to operate.

- Diagnose and treat the condition of laying hens in time. The caged chickens facilitate the farmers to diagnose and treat the laying hens in a timely manner when they are sick, and at the same time reduce the difficulty of diagnosis and treatment, and the laying hens are in good physical condition.

- It is convenient to feed. The chicken cage for sale in Nigeria is convenient for the farmers to feed the laying hens, reducing the workload and improving the work efficiency.

- Save labor costs. The use of poultry farming equipment has allowed the development of intensive poultry farming projects. The fantasy of 2 people managing 20,000 birds becomes a reality. Poultry Farming Friends is no longer hiring managers. You can manage the chicken farm yourself.

- 5. The utilization rate of the chicken house is high. The number of battery cages installed in the chicken farmis more than 3 times more than that of deep litter-raised chickens.

6.The commercial battery cages is widely used in large-scale farming by farmers in tropical countries such as Africa, Southeast Asia, and South Asia.

Poultry Farming Equipment Features and Analysis

Poultry farming equipment is a special machine used by chicken farms in the production process of chicks, breeders, broilers and laying hens. Chicken farms can be divided into free-range and battery cages. Chicken raising equipment includes: layered chicken cage system, ventilation equipment, water supply equipment, feeding equipment, egg collection equipment, manure cleaning equipment, lighting equipment, etc.

- Battery cage system. There are mainly two types of A-type chicken cages or H-type chicken cages. Farmers mostly take 60-70 days of age and transfer them directly to laying hens. Laying hens are basically raised in cages. At present, there are many manufacturers producing chicken cages, which can be purchased according to the actual situation.

- Ventilation equipment. The closed chicken house must be mechanically ventilated. According to the direction of airflow in the house, it can be divided into two types: horizontal ventilation and vertical ventilation. Lateral ventilation means that the direction of airflow in the house is perpendicular to the long axis of the house, and longitudinal ventilation refers to a ventilation method in which a large number of fans are concentrated in one place, so that the air flow in the house is parallel to the long axis of the house.

- Water supply equipment. From the point of view of saving water and preventing bacterial contamination, nipple drinkers are the most ideal water supply equipment, and high-quality water-tight drinkers must be selected.

- Feeding equipment. The feeding trough is mainly used, and the caged chickens all use long through troughs. This feeding method can also be used when brooding flat, or the hanging bucket can be used for feeding. The shape of the feeding trough has a great influence on the throwing of the feed for the chickens. The feeding trough is too shallow and there is no edge protection, which will cause a lot of feed waste.

- Poultry Manure cleaning equipment. General chicken farms use manual manure removal on a regular basis, while larger chicken farms can use mechanical manure removal.

Creating a modern chicken farm requires not only modern chicken raising equipment, but also a modern farming concept.

How to choose poultry battery cage system?

There are many different sizes and types of battery cages on the market. How do breeders choose the most suitable cages for their chickens? This is determined by many factors.

You can choose the right battery cage based on the weight and size of your poultry and the climate in your country. For example, 1.5KG and 2.5KG require different size layer cages. In hot and cool weather, the lifespan of a laying hen of the same quality can vary greatly. There are large and small spaces, and if the area is large, you can choose A-type chicken cages or H-type chicken cages. So price is not the only consideration.

The raw materials of poultry equipment layer chicken cages are divided into cold galvanized and hot-dip galvanized. In general, hot-dip galvanizing is more corrosion resistant and lasts longer.

There are many types of chicken cages, and most of them are made of steel wire now. Generally, multi-layer chicken cages are used for raising chickens, and electric battery chicken cages are used for laying hens.

There are many types of battery chicken cages, such as three layers and four layers, etc. Batch breeding generally chooses multi-layer chicken cages.

When buying chicken cages, pay attention to the connection of the bottom net between each layer of cages. The connection should be thin and there should not be too much gap. If the gap is too large, it may cause the eggs to fall.

Prospects for the development of broiler and poultry farming projects

Global chicken consumption continues to grow, and it is foreseeable that broiler products will become the number one meat consumer in most countries in the near future. Along with the economic development and the continuous improvement of people's living standards, the total demand for chicken meat is also gradually increasing. Therefore, it is profitable to use battery broiler cages to develop poultry farming.

Rapid growth

Broiler chickens grow much faster than regular chickens. In general, newborn chicks can grow up to 2 kg after two months of feeding. For a broiler, it probably won't grow shag for two months. It has to be said that the growth rate of broilers is still very fast, which means that the income return of breeding broilers is fast.

Short Growth Cycle

Due to the fast growth rate of broilers, their growth cycle is naturally shorter. If nothing else, it usually takes only two months from hatching to slaughtering, and at this time, the weight of the broiler has fully reached the level of the market. After the slaughter, farmers do not need to spend a long time cleaning the chicken house, and can quickly put into the breeding of the next batch of broilers. If the breeding management goes well, five batches of broilers will be launched within a year. It's entirely possible.

High Breeding Density

Because broilers are quieter by nature, they don't like to move or fight each other. Therefore, the space utilization rate of the broiler house is relatively high. The breeding density of poultry cages for broilers is also relatively high. Therefore, the quantity of each batch of broiler chickens on the market is quite considerable. Usually, as long as the farmers do a good job of air circulation and disease prevention in the chicken house, and increase the breeding density appropriately, they can sell more broilers on the market.

How to Clean and Disinfect Poultry Farming Equipment?

With the improvement of living standards, people's demand for chicken is also increasing. However, environmental problems in chicken cages will directly affect the growth status and production efficiency of chickens. Therefore, the chicken cage factory recommends cleaning and disinfection in the chicken cages.

1.Cleaning of poultry farming equipment prices in south africa and cages: The main design is galvanized mesh, which is not easy to scratch or pock under normal conditions, but some impurities, such as chicken feathers, feed and chicken manure, will be attached during use.

After a long time, it may scab and harden, so we need to take it out and clean it, do not wipe it with a stiff brush, soak it after washing, soak the dirt to soften it, and then rinse it with water. During the entire cleaning process, do not recommend the use of cleaning agents, because the ingredients contained in the cleaning agents will corrode the chicken cage equipment to a certain extent.

2.Disinfection of chicken cages: Chicken cages for sale maintain high density, so spray or fumigation is used for disinfection. If the disinfection is not clean, bacteria and viruses will easily remain, which is not conducive to future feeding and disease prevention. Pay attention to the rotation and amount of disinfectant when disinfecting. Before fumigation, close doors and windows, plug all gaps, and then calculate the dose of the drug based on the volume of the coop. After disinfection, open doors and windows for ventilation for 1-2 days to prepare for hatching.

The above is a relatively simple cleaning method. In fact, in order to keep the chicken cage system clean and tidy, it is necessary to carefully maintain it at ordinary times. In normal use, we try not to pull, pull and close the door hard to reduce the collision of materials. When raising chickens at ordinary times, do not sprinkle the feed around the cages, and do not soak them in liquid. Usually the correct installation method is to use it, which is an effective way to prolong the service life of chicken cage system.

How to supply the required nutrition for laying hens?

More poultry farming friends choose to use battery layer cages to raise commercial laying hens. Feed is the only source of nutrition for poultry. So how can our poultry farmers supplement adequate nutrition for chickens during the laying period?

Commercial feed from a reliable feed store has all the nutrients that chickens need in the correct proportions. A balanced diet is necessary for optimal growth and production. If you are using a good diet that meets the flock's dietary needs, supplement with other foods that can disrupt the balance of the diet.

The daily feed consumption of chickens depends on the composition of the diet. Chickens usually adjust their feed intake to meet their energy needs. Feed intake decreases as the energy content of the diet increases, and vice versa.

Ambient temperature also plays an important role in determining how much feed a flock will consume. In hot weather, feed intake is reduced. In cold weather, chickens' feed intake increases because the chickens use more to provide the extra energy needed to maintain their body temperature.

The purpose of a laying hen diet is to optimize egg production (based on egg number, egg size or egg quality), provide the nutrients needed to support health and maintain an ideal body weight. As with laying hens, different breeders recommend different feeding strategies for their birds, including the amount of different diets fed during the laying phase. Calcium increases to form eggshells.

The above are the ways and methods shared by layer cage manufacturers to increase nutrition for laying hens in laying hen cages. I hope there is a place that can help poultry farmers.

How to effectively cool chickens ?

Summer arrives. A topic that poultry farmers have to mention is how to prevent heatstroke in summer. Every summer, chickens die from heat stroke due to high temperature. Large-scale farms have poultry farming equipment price: fans and water curtains. Cooling down is relatively simple. Today we talk about a few other ways.

- Increase ventilation

Increased ventilation can speed up the air movement inside the house. Take away the heat emitted by the chickens, thereby reducing the body temperature of the chickens. The decrease in body temperature can also greatly reduce the possibility of heat stroke. Just like we are at the same temperature and in the same environment, the feeling of wind and no wind is completely different. Therefore, in the absence of a water curtain, we should increase the ventilation volume as much as possible to reduce the body temperature of the chickens. It is recommended to use a cooling fan. It should be noted that the water supply and the fan need to be set up separately.

- Shading and cooling

For many free-range flocks, we can build shade nets in the hot summer. Or do more greenery around the chicken farm and plant some trees to block the direct sunlight, so as to achieve the effect of cooling. For the construction of the roof of the chicken coop, it is best to use white foam board at the time of construction. This can reduce the radiation of sunlight and reduce the absorption of heat.

- Change the feeding time

When feeding chickens in high temperature summer, try to avoid high temperature periods. During the high temperature period, the temperature is high. At this time, feeding increases the activity of the chickens, and the chickens are prone to heat stroke due to fighting and fighting. The feeding time can be changed to the time period when the temperature is relatively low in the morning and evening.

- Ensure water supply

In the summer heat, the temperature of the chicken house is high. Chickens live in chicken battery cages, which requires ensuring that the chickens can drink enough cool water at all times, and it is also necessary to ensure that each nipple drinker can produce water to prevent heat stroke due to lack of water. Mild water shortage will result in reduced egg production, and severe water shortage will result in a significant drop in egg production or even death from heat stroke.