Problems that should be paid attention to in farms that use automated poultry farming equipment

%AM, %18 %385 %2021 %08:%NovAutomatic poultry farming equipment to raise chickens has become an indispensable equipment for farmers to carry out chicken projects. There are the following issues that need to be paid attention to by farmers.

First, when using automatic chicken breeding equipment for breeding, attention should be paid to prevent the presence of high concentration of ammonia in the chicken house. This gas is relatively harmful to the chickens. When the chickens can smell it It is too late for the smell of ammonia. They can smell this gas, indicating that the concentration of the gas is relatively large. At this time, it will enter the body of the chicken and induce a series of respiratory diseases. Therefore, breeding The person in charge of the farm should take corresponding measures to prevent ammonia from harming the flocks.

Second, when using automated chicken breeding equipment for breeding, it is also necessary to pay attention to the daily maintenance and disinfection in the chicken house. It is recommended to use the automatic manure cleaner at least once a day to reduce fecal pollution and at the same time reduce ammonia. In addition, attention should be paid to the disinfection of various automatic equipment, so as to take protective measures.

Third, it is necessary to control the humidity and temperature in the chicken house appropriately. The automatic poultry farming equipment factory recommends that the humidity of the chicken coop in each farm should be kept between 60% and 70%, which is more conducive to the growth of the chicken group. , The temperature of the chickens during laying should be kept at about 20 degrees Celsius, so that the chickens can lay eggs smoothly.

The above are the three aspects that farmers should pay attention to when using chicken raising equipment to raise chickens.

Problems that should be paid attention to in farms that use automated poultry farming equipment

%AM, %18 %385 %2021 %08:%NovAutomatic poultry farming equipment to raise chickens has become an indispensable equipment for farmers to carry out chicken projects. There are the following issues that need to be paid attention to by farmers.

First, when using automatic chicken breeding equipment for breeding, attention should be paid to prevent the presence of high concentration of ammonia in the chicken house. This gas is relatively harmful to the chickens. When the chickens can smell it It is too late for the smell of ammonia. They can smell this gas, indicating that the concentration of the gas is relatively large. At this time, it will enter the body of the chicken and induce a series of respiratory diseases. Therefore, breeding The person in charge of the farm should take corresponding measures to prevent ammonia from harming the flocks.

Second, when using automated chicken breeding equipment for breeding, it is also necessary to pay attention to the daily maintenance and disinfection in the chicken house. It is recommended to use the automatic manure cleaner at least once a day to reduce fecal pollution and at the same time reduce ammonia. In addition, attention should be paid to the disinfection of various automatic equipment, so as to take protective measures.

Third, it is necessary to control the humidity and temperature in the chicken house appropriately. The automatic poultry farming equipment factory recommends that the humidity of the chicken coop in each farm should be kept between 60% and 70%, which is more conducive to the growth of the chicken group. , The temperature of the chickens during laying should be kept at about 20 degrees Celsius, so that the chickens can lay eggs smoothly.

The above are the three aspects that farmers should pay attention to when using chicken raising equipment to raise chickens.

How should poultry farms manage chicken house in the environment of the Covid-19

%AM, %17 %384 %2021 %08:%NovUnder the normalization of the prevention and control of the Covid-19, ensuring the healthy breeding and safe production of poultry, strictly preventing the occurrence of poultry epidemics, and comprehensive biosecurity have become the top priority and should be highly valued. So, how should poultry farmers manage their chicken house?

Personnel management of poultry farms. The personnel entering and exiting the chicken coop should be disinfected, changing work clothes and other routine disinfection and epidemic prevention measures. Minimize the outing of internal personnel and reduce the source of the virus that chickens get sick.

Disinfect the chicken house. Use a suitable disinfectant to spray the chickens for disinfection. The spray point should be 70-90cm away from the chicken body, and the size of the droplets should be controlled, and the chicken feathers should be moist. Properly increase the temperature in the chicken house by 2 to 3°C before spraying. Disinfection with chickens can not only kill pathogenic microorganisms, but also reduce dust, increase humidity and reduce temperature, and purify the air in the house. Especially when infectious diseases occur in chickens, effective spray disinfection should be carried out on the chicken coops, the frequency of disinfection should be increased appropriately, and relevant vaccines or drugs should be vaccinated in time.

Vaccine immunity. Newcastle disease, avian influenza, infectious bronchitis, etc. are still infectious diseases that are serious to poultry, and routine immunization of these acute infectious diseases should be done. Develop scientific immunization procedures and strict immunization systems, select qualified vaccine products, follow the correct immunization methods, strictly operate, precise immunization, and timely conduct antibody monitoring to ensure a good immunization effect. In particular, it is necessary to scientifically formulate immunization procedures based on the local epidemic situation and the actual situation of the site to ensure that the threatened disease is immunized.

Feeding management. To scientifically control the environment in the chicken house, the first is to maintain a suitable stocking density, provide balanced feed nutrition, reasonable ventilation, adequate light, maintain a suitable temperature and humidity and good air quality, and avoid harmful gases. Farmers can use the automatic poultry manure removal system to remove manure in time and do harmless treatment to prevent manure-sourced pollution.

If conditions permit, do a good job of intelligent, automatic, and mechanized production and management to ensure that poultry have a suitable and healthy living and production environment, and to improve breeding efficiency.

The above is the management of modern poultry farming equipment manufacturers to deal with the Covid-19 in terms of chicken house management, epidemic prevention and other aspects. I believe we will definitely overcome the epidemic and return to a healthy and happy world without the epidemic.

The primacy of chicken raising equipment on temperature

%AM, %16 %406 %2021 %08:%NovThe chicken house environment control device is installed on the chicken breeding equipment to realize the reasonable regulation of the temperature and humidity in the chicken house. In order to ensure the thriving growth of chicks, the temperature of the chicken house should be controlled within a reasonable range by the chicken-raising equipment.

The temperature control of the chicken raising equipment requires different temperature requirements at different growth stages of the chicken: the chicken just out of the eggshell needs 32 degrees Celsius to 34 degrees Celsius. With the increase in week age, the temperature will gradually decrease, that is, it will decrease by about 2 degrees Celsius for every additional week of age, and it is advisable to maintain it at 21 degrees Celsius to 23 degrees Celsius by the sixth week.

1. The chicken breeding equipment must work in strict accordance with the safety operating procedures, and cannot be overloaded. The safety and reliability of the equipment must be ensured. If there are unsafe factors, it should be eliminated in time;

2. Regular oil refueling or oil change, no dry friction phenomenon can occur, to ensure that the oil pressure is always at normal filling and the oil path is unblocked;

3. Tools should be placed neatly, and the lines and pipes should be organized;

4. Ensure that all parts of the equipment will not leak oil or air, and clean the surrounding debris.

Layer cage manufacturers take you to understand the stress factors that cause chickens

%AM, %12 %415 %2021 %08:%NovWhen raising laying hens in layer cage, we should understand some of the stress factors that cause chickens?

(1) Environmental factors. For example, high temperature, high humidity, cold, lack of oxygen, noise, light, strong wind, etc. High temperature stress is common, severe, and serious in production. If the temperature exceeds 35-38°C, it can cause chickens to breathe faster , The feed intake is reduced, the egg production is reduced, and even death is caused.

(2) Management factors. Mainly include poor ventilation of the chicken house, excessive density, excessive light, sudden or insufficient feed and drinking water, and poor feed quality. It is caused by improper management.

(3) Disease factors. When pathogenic microorganisms invade, the body will mobilize all positive factors to resist the disease, and at the same time, there will be a series of clinical reactions, such as decreased appetite and depression.

(4) Inevitability factors. It mainly includes immunization, disconnection, transfer, capture, disinfection, etc. It is an inevitable production link in feeding management, but scientific and reasonable methods and methods should be adopted to minimize the intensity of stress response.

Before using layer egg cages to raise chickens, what do farmers need to prepare?

%AM, %08 %454 %2021 %09:%NovAs the market demand for eggs and chicken continues to increase, many users want to join the army of chicken raising in order to improve their own benefits. For novice farmers, they want to use layer egg cages and automatic equipment to achieve Intensive farming requires learning and preparing all aspects of chicken farming. So what do we need to prepare for chicken farming?

Adjust the temperature before entering the chickens: chickens are raised from the chicks. The chicks are newly born chickens, and all functions of the body have not grown well. Therefore, it needs a relatively high temperature to adapt to the environment and grow healthy. Before the chicks enter the chicken house, the breeder should adjust the temperature of the chicken house in advance, and adjust the temperature of the chicken house to above 28°C, and then gradually reduce the temperature as the chicks grow.

Disinfect before entering the chickens: most of the chicken houses of novice farmers are new, and many farmers think that disinfection is not necessary. In fact, it is not the case. Whether it is a new or old chicken house, it must be carefully disinfected before entering the chicken. In this way, the hygiene and health of the chicken coop can be ensured. It is recommended that the farmers thoroughly disinfect the chicken coop within one week before entering the chicken.

Check whether the utensils are complete: chickens need a lot of utensils, such as feeders, sinks, drinking fountains, lighting equipment, thermometers, hygrometers, syringes and other utensils. You must purchase these utensils before raising the chickens so that you can Don't panic during the process of raising chickens. You can find out what equipment you need in time. It is unnecessary to buy and waste time.

Choose good vaccines and immunization equipment: In the process of raising chicks, in order to prevent various infectious diseases of chicks, farmers need to immunize chicks in a timely manner, so before raising chickens, farmers must learn how to do well with chicks. At this stage, you need to carry out that kind of immunization, and then choose a good vaccine and immunization equipment.

Vehicle preparation: Farmers must determine how many chicks they need to raise before entering the chickens. After determining the transportation quantity, choose different vehicles.

The above are the things and things that need to be prepared before raising chickens shared by the manufacturers of automatic poultry raising equipment. I hope that farmers can make good use of automated equipment to improve the efficiency of raising chickens, raise healthier chickens, and promote the development of the breeding industry.

What problems should be paid attention to when using automatic poultry breeding equipment to raise chickens

%AM, %05 %407 %2021 %08:%NovNowadays, automatic poultry chicken raising equipment is emerging in endlessly, and many farmers will rely on some automatic chicken raising equipment to raise laying hens in order to improve work efficiency. Although the technology and methods of raising chickens have been improved, some farmers still cannot get good economic benefits. In order to help the majority of farmers improve their scientific management level and achieve better economic benefits, automatic chicken cages equipment manufacturers tell farmers the standardized procedures for raising chickens that need to be paid attention to when using fully automatic poultry farming equipment.

- At present, the disinfection of fully automatic chicken breeding equipment is an effective way to ensure the hygiene of the chicken house. Correct and reasonable disinfection can kill pathogenic microorganisms in the chicken house in time. Many farmers do not pay attention to disinfection or the disinfection system is not perfect, and does not follow conventional operating procedures, resulting in poor disinfection effect and poor sanitary conditions in the chicken house.

- Immunization is a very effective way to prevent infectious diseases in chickens, but many farmers are very irregular in vaccination operations, or do not know the correct vaccination method. Therefore, the chicken immunization failed, which not only increased the breeding cost of farmers, but also failed to achieve good economic benefits.

- Generally, many farmers lack scientific and rigorous awareness of epidemic prevention when they are in chicken farms. When someone returns to the chicken house, they do not pay attention to ultraviolet disinfection and enter the chicken house at will without changing their disinfected clothes and shoes. This is likely to lead to the transmission of diseases.

- In the four seasons of the year, the seasonal weather changes are great. Farmers should take preventive measures against weather changes. However, many farmers did not take preventive measures when encountering sudden weather changes or other stress factors, which led to the outbreak of chickens. If the weather becomes cold, warm measures should be taken to prevent the entry of cold air; if the weather is very hot, measures should be taken to cool down, and the environment should be ventilated.

- Nowadays, there are many kinds of feeds on the market. Pay attention to the price of feeds when buying, and don't change the feeds at will. Changing the feed will generally reduce the diet of the laying hens, and the egg production will be greatly reduced; broilers generally do not grow long, and the entire group will be seriously ill.

I hope that the above summary can bring some help to farmers.

Laying hen equipment should also be ventilated frequently in winter

%AM, %03 %435 %2021 %09:%NovWhen using laying equipment to raise chickens, remember to ventilate frequently. Although the weather has become cold now. The smell in the chicken coop is much less than in summer. But the ventilation that should be done is also indispensable. The time for laying hens to ventilate is getting shorter and shorter. This is not conducive to the growth of chickens. It is easy to make chickens sick.

The laying hen equipment must be mechanically ventilated according to the direction of airflow in the house. The chicken breeding equipment is equipped with two modes, which can be horizontal ventilation and longitudinal ventilation. Horizontal ventilation means that the direction of airflow in the house is perpendicular to the long axis of the house. Longitudinal ventilation refers to the concentration of a large number of fans in one place. So that the airflow in the house is parallel to the long axis of the house.

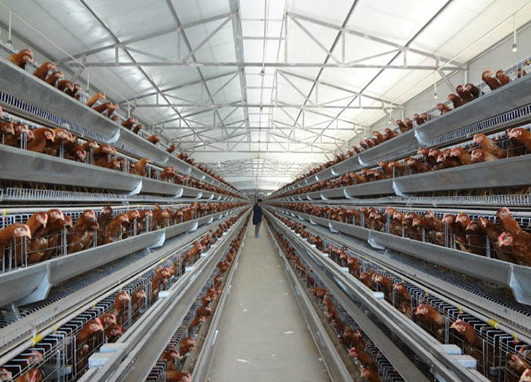

Features of laying cage equipment:

1. Layered breeding, the number of layers is optional, up to 10 layers, the breeding density per unit space is extremely high, the breeding output is large, and the efficiency can be reasonably doubled.

2. Automatic feeding and drinking, saving manpower, improving labor productivity, and increasing the egg-to-feed ratio.

3. Automatic egg collection, reducing labor costs.

4. Conveyor automatic cleaning of manure, dry and sanitary, saving labor, manure can be cleaned multiple times a day, greatly reducing respiratory diseases of chickens.

5. Concentration of feeding reduces the amount of mobile contact of staff in the chicken coop, which is beneficial to the prevention and control of chicken diseases.

Based on all the above, do you have a more in-depth understanding of the benefits of layer equipment ventilation?

More...

How to improve the quality of chicken?

%AM, %02 %403 %2021 %08:%NovNowadays, more and more farmers are concerned about the quality of chicken meat. With the excellent quality of high-quality chicken, farmers will be able to make more money. The following methods will help raise broilers in a new way. You can have a try.

- Battery broiler cages to raise chickens. It is more convenient to manage chicken farmers in chicken cages.

Automatic chicken raising equipment can automatically clean manure, drink water, feed, ventilate, etc., to provide more scientific management of chickens.

- In addition, banana peel can be used as a chicken feed additive. Chop the banana peel, dry and crush. Adding 10% banana peel to chicken feed can increase the feed conversion rate, promote the growth of broilers, reduce costs, and improve economic benefits.

- According to the experiment of scientists, before slaughtering the chicken, feed the spice chicken feed to the broiler to make the meat more tender and delicious and extend the freshness period. The principle is that the fat in the meat is oxidized to cause deterioration, but some spices such as cloves, pepper, sweet pepper, ginger, etc. have functions similar to medicinal materials. Therefore, these spices can improve meat quality and extend the shelf life.

This is the shared method to improve the quality of broilers. I hope that some of them can help farmers.

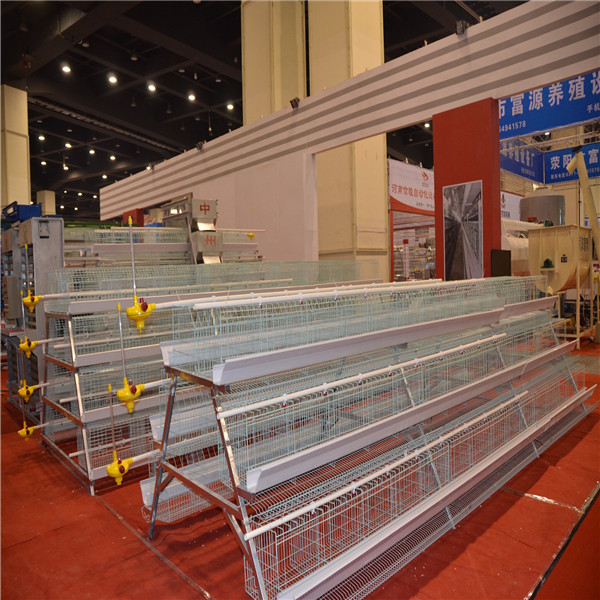

Reasons why chicken cages are prone to bending

%AM, %27 %448 %2021 %09:%OctThe chicken battery cages with reasonable structure and excellent quality has a service life of 15-20 years. It can provide a relatively comfortable living environment for chickens and ensure the normal potential of chickens. However, for chicken cages with poor structure and poor quality, either the chicken will deform and the solder joint will crack as soon as it is put into the cage, or the chicken will be stuck continuously, which will make the chicken in a state of stress for a long time, make it difficult to give full play to the normal production performance, and cause huge losses.

It can be seen that the quality of layer cages is directly related to the economic benefits of the chicken industry. Whether it is cage manufacturers, chicken farm technicians, or general individual chicken farmers, they should attach great importance to this. Therefore, it is very important to choose a good quality layer cages.

The production materials of chicken cages require cold drawn steel wires. Inferior steel quality is generally manifested by low steel wire hardness and poor elasticity, which reduces the overall strength of the chicken cage and is easy to deform. For the finished product that has been welded, the quality of the steel wire can be identified from the following aspects:

High-quality steel wire has high hardness and strong elasticity. Use your fingers to pinch the two adjacent steel wires on the chicken cage sheet where the distance between the welding points is large. You should clearly feel the elasticity of the steel wire. When the force is moderate, the slight bending caused by the pinching can basically reset itself. , The steel base wood will not be deformed if you use light force. If the steel has a low hardness and poor elasticity, it will produce irreversible deformation if the adjacent steel wires are pinched with light force by hand. If the steel wire is severely bent without resetting with moderate force, the steel wire feels almost inelastic, so pick up the cage to make it When it fell on the concrete floor, his voice was short and muffled.

The cage plate made of high-quality steel wire has a loud and high sound on the ground, and the reverberation is long. The steel wire with extremely poor hardness will produce small wavy bends when straightened, which is very obvious from the eye, and the high-quality chicken cage steel wire will never appear such bends. A chicken cage welded with a low-hardness steel wire, even if the solder joints are firm, the chickens will be overwhelmed and bowed severely after being basketed, which can cause water and trough deformation or breakage, which is not only inconvenient for management, but even Make it difficult for chickens to eat and drink