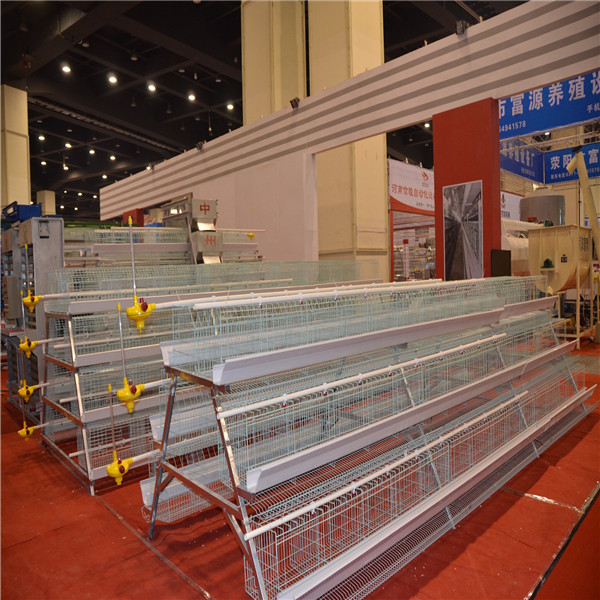

The battery layer cage breeding model has been widely recognized by the majority of layer farms

%AM, %27 %416 %2021 %08:%OctUnder the development of aquaculture automation, the battery layer cage breeding mode has been widely recognized by the majority of layer farms. This breeding method has a small area and high space utilization. The layered cleaning of chicken manure can not only improve the utilization rate of chicken manure, but also It also reduces the degree of environmental pollution. At the same time, labor intensity is reduced and productivity is improved. Although stacked cages have many advantages, the premise is to know how to use them and how to manage them.

Due to the inconvenience of multi-layer cages, it is inconvenient to catch the chickens. The laying time for laying hens can be appropriately extended. Vaccines that require immunity, such as Newcastle disease, infectious bronchitis, avian influenza, and egg drop syndrome, should be completely immunized before being basketed. over. When the egg production rate reaches 5%, the prenatal feed should be replaced with peak feed. The refueling will take one week for the transition. At this time, the feed should maintain high quality and stable nutritional content, and do not change the finished feed and raw materials at will.

In addition to the conventional power system, a generator that matches the chicken farm must be required and can be automatically switched. To ensure uniform light in the house, light bulbs can be installed on a staggered level or row of lights can be used. In order to ensure the service life of the equipment, lubricate the transmission parts such as the transmission sprocket and gears of the transmission box once a month when in use. Clean the surface of the egg roller and the fecal roller in time to prevent the accumulation of debris from swelling the fecal belt or breaking the roller shaft.

Clean up the impurities in the soft and broken egg collection tray in time. The ventilation system should be adjusted appropriately for side wall ventilation and roof ventilation according to the different seasons. Always keep the lighting bulb clean to prevent affecting the light intensity.

How to manage laying hens to increase egg production?

%AM, %25 %419 %2021 %09:%OctIncreasing the egg production of laying hens should be hoped by farmers. So is there any way to increase egg production? You can start from the following aspects.

The first is management. The chicken cannot speak, it needs to be taken care of. Now automated poultry chicken raising equipment can help farmers better manage their chicken coops and realize a fully automated breeding system.

The second is the feed. To reach the various nutritional requirements required by the chickens at all stages of growth, it is not possible to reduce costs with taste, and eating cheap feeds does not meet the growth of chickens, or even moldy feeds.

The third is that the layer cages must have a reasonable breeding density to ensure that each chicken can eat the feed. The breeding space is so large. If the breeding is over, there will be no way to create a good environment for the chickens.

The fourth is to strictly follow the preventive procedures to prevent and administer drugs, observe more, learn more, and eliminate the disease in the bud.

In short, if you want chickens to lay more eggs, from brooding to laying eggs, no link should be sloppy. These are all preparations for laying eggs. If you can do this, you can give full play to the potential of chickens, and there is nothing that does not increase production.

Ways to increase broiler production

%AM, %20 %425 %2021 %09:%OctAs the price of pork rises, the demand for its substitute chicken meat has risen sharply. The production of broilers has become a concern for farmers, so what measures should be taken to increase the production of laying hens?

Choose a good chicken breed

The type of chicken also affects the yield of the chicken. Farmers must not be greedy for cheap when buying chickens. They need to choose strong disease resistance and adaptability. This kind of breeding can make the breeding process much simpler. The growth rate of broiler chickens is also the key to determining economic benefits. Try to choose breeds that grow faster, so that the cost recovery speed can be accelerated, so that the next generation of broiler chickens can be raised with funds to continue their breeding.

Use broiler cages for intensive farming

Now intensive chicken farming has become a breeding trend around the world. If broiler chickens are raised, they can be well taken care of. The automated drinking water system and automated manure removal system help farmers to raise chickens better. In addition, the chickens live in chicken coops and have relatively little activity, so the feed conversion rate is improved.

Strengthen management.

Farmers need to manage chicken flocks, isolate and treat sick chickens, and eliminate sluggish chickens. And it is necessary to observe the activity and eating of the chickens regularly every day.

Use good quality feed

The nutrition of good feed will be more balanced, which can promote the growth of chickens. Farmers try not to buy cheap and inferior chicken feed if they want to increase broiler production. Farmers must choose feed with safe ingredients, because it can promote the healthy growth of chickens.

In fact, no matter what kind of chickens are raised by the farmers, if the chickens are raised in poultry battery cages, the probability of chicken diseases will be reduced, and it will be more conducive to the management of the farmers, and the farmers who use automated breeding equipment will no longer need to hire. Personnel, one person can easily raise 10,000 chickens.

The main points of using poultry breeding equipment to prevent chicken diseases

%AM, %19 %393 %2021 %08:%OctThe use of various poultry raising equipment to assist in raising chickens is now the breeding method of most large-scale chicken farms. When raising chicken equipment, labor intensity and labor costs are greatly reduced, and the environment of the chicken house can be better controlled. However, the control of chicken disease prevention and control is still the focus that farmers cannot ignore. Now I will introduce the key points of chicken disease prevention and control for farmers.

- Feeding fresh feed: When choosing feed, many farmers will buy a lot of feed for storage and use, so if the storage is unreasonable, it will easily lead to moldy and deterioration of the feed, which will affect the health of the chickens after they are eaten. Therefore, when choosing feed, farmers should not buy too much at one time. It is recommended to buy the amount for one week. When storing it, it should also be stored in a dry environment to avoid deterioration.

- Frequent cleaning of manure: Chicken coops produce a lot of manure every day. If the farmers do not clean it in time, the ammonia in the chicken house will exceed the standard. Ammonia is a harmful gas that can seriously affect the health of the chickens. Therefore, frequent removal of manure is also the key to disease prevention and control. Conditional farmers can install chicken-raising equipment manure cleaners to clean manure, which saves time and effort, and has a good manure removal effect. The manure can be cleaned every day to avoid the generation of ammonia. It can purify the environment of the chicken house.

- control the temperature and ventilation: When ventilating and controlling the temperature of the chicken house, the farmers should follow the principle of “as far as possible to ensure the temperature under the premise of ensuring normal ventilation”. In addition, there is also the humidity in the chicken house. Pay attention to the balance between temperature and humidity under high temperature and low temperature; when the temperature is high and the humidity is high, it is easy to form a sultry environment, which will have obvious adverse effects on the growth and health of the chicken.

Automated poultry farming equipment manufacturers share the methods to prevent chicken diseases. I hope that farmers can use them to raise chickens to help chickens grow.

How to clean the drinking fountain of chicken farming equipment

%AM, %18 %390 %2021 %08:%OctWater is the source of life. Without water, no creature can survive normally. Especially when we are doing breeding, chickens need a lot of water to ensure that there is enough water in the body. If the chicken lacks water, it will cause a series of problems. Not only that, the quality of water is also the root of the health of the flock. If the quality of the water used by the chickens every day is poor, it will lead to chicken is sick. In the normal operation of chicken raising equipment, in order to avoid these undesirable phenomena, scientific methods must be used to add water to the chickens and clean the chicken drinking equipment. Cleaning the drinking fountains of chicken farming equipment is also one of the things we must do. Today, the editor will introduce how to clean it.

1. Many people find it troublesome to clean the chicken water dispenser, so it usually takes a long time to install and use, and the water dispenser is blocked and used abnormally if it is not cleaned. This is incorrect behavior.

2. In the drinking fountain of the chicken breeding equipment, the discharged water is left in the pipeline, and there are several drinking openings in the sewage pipe section.

3. The water stays in the drain pipe to prevent the water from going bad and polluting the drinking water system.

4. For drinking water or flushing water, pipes and water tanks should be used to prevent vacuum from accumulating in the drinking water system, causing precipitation, deterioration and water pollution.

5. In production practice, if there are foreign objects in the drinking fountain of the chicken breeding equipment, you can open the end of the pipe so that there is a pressure pipe with fast water flow at the other end of the high-pressure water pipe, and flush the nipple with high-pressure fast water to make the drinking pipe sticky and deteriorate. Remove foreign matter and sediment in the high-pressure water pipe. If there is a biofilm on the short section of the water pipe, hydrogen peroxide can be used to remove the biofilm.

6. This method is often used to flush the pipes of chicken breeding equipment, which can prevent the formation of sticky and deteriorated foreign matter and the deposition of foreign matter in the water, thereby ensuring the cleanliness of drinking water.

After cleaning the chicken raising equipment, we must clean up all the remaining feed on the feeding line, especially the feed left in the trough, the corner of the conveyor chain and the hopper. When cleaning, use a vacuum cleaner, blower, iron brush, etc. In addition, under the feeding chain, insert sawdust with an abrasive tool to run the chain and remove the fixed feeding residue.

How to choose battery chicken cages for intensive chicken farming

%AM, %16 %145 %2021 %02:%OctIf you choose to intensively raise chickens, you should know what chicken battery cages should be used. Cage-raised chickens are still a difficult task in choosing a cage. For this problem, the following aspects are briefly summarized, and I hope it will be helpful to you when choosing to buy chicken cages.

- The brooding cage (1~40 days old) generally adopts 3~4 layer overlapping type. The total height of the cage is about 1.7 meters, and the total length depends on the scale of rearing. The height of the feet of the cage is 100-150 mm, the length of each single cage is 1800 mm, the height of the cage is 300-400 mm, and the depth of the cage is 400-500. Millimeters, the mesh of the cage is generally rectangular or square. The hole diameter of the bottom net is 12.5×12.5 mm, and the hole diameter of the side net and the top net is 25×25 mm. Each cage can accommodate about 40 chicks.

- Growing cages (41-140 days old), generally three-layered, with an overall width of 1.6-1.7 meters and a height of 1.7-1.8 meters. Each single cage is 1800 mm long, 400 mm high and 420 mm deep. The bottom mesh of the cage is 20-40 mm. The meshes on the top, sides and back of the cage are 25×25 mm. The cage door is 140-150 mm wide, and each single cage can accommodate 7-15 chickens.

- Cage for laying hens(141 days old ~ end of laying). Generally three or four floors. The length of the chicken cage is 1800 mm. The width is 450 mm and the length is 410 mm. This is the data of a chicken coop with four floors and five doors. It can breed 160 chickens.

The above is the detailed data of brooding chicken cages, broiler cages, and layer cages. Farmers can choose the cage equipment according to the type of chicken.

How to clean the broiler cage?

%AM, %15 %408 %2021 %08:%OctMore and more manufacturers use broiler cages. The chicken coop can be reused. So how to clean the broiler cage reasonably?

The cleaning of chicken sheds and layer cages, use drinking water to clean the chicken sheds and layer cages, and ensure that no dead ends are left during cleaning. The trough and water line should also be completely cleaned to prevent residual concentrated feed, waste and excrement.

Clean the tray of the broiler cage. The cage gasket of the broiler cage is placed at the bottom of a tray. Such trays should be removed at least once a week, and cleaned with wet and cold towels.

In the case of cleaning the chicken coop, connect to the accessories, scanner or rake out the old wooden paring and the old hen chicken shed. If necessary, clean the wooden floor. Sprinkle it into the chicken shed with a thick layer of cedar wood, between 8 inches and 12 inches deep. From grains sometimes the wooden floor of the chicken shed. Add a thin layer of cedar wood and sprinkle a lot of ammonia flavor per chicken shed from scratch.

After cleaning, we must do a good job of disinfection and sterilization of chicken cages. During disinfection and sterilization, the disinfectant should be applied alternately, and the amount of use must be mastered. Before fumigation and disinfection, close the windows and doors of the chicken shed, block all gaps, and then calculate the amount of medicine used according to the capacity of the chicken shed.

We need to clean up the broiler cages once a week. Under the condition of ensuring environmental sanitation, we can also enable the chickens to obtain a stronger natural environment for growth and development, thereby enhancing the chicken’s talents and generating more and more for customers. Profitability.

Precautions for the construction of chicken coops on large chicken farms

%AM, %14 %432 %2021 %09:%OctNow more and more large chicken farmers and chicken demonstration bases are introducing advanced automatic chicken farming equipment, advanced technology and management of automated chicken farming equipment, and a reasonable layout, which is increasingly changing the traditional breeding concepts of the majority of farmers. It is also adopted by more and more breeding companies. In the past few years, fully automated chicken breeding equipment has blossomed all over the market, affecting and leading the traditional breeding mode to a higher automatic breeding mode.

Construction of chicken house in large-scale chicken farms and matters needing attention;

- The choice of venue.

Large-scale chicken house should be built with enclosed chicken coops. The purpose of enclosed chicken house is to reduce the spread of diseases. Then the site should be selected in a relatively open place, without the blockage of trees and grass, because trees and grass are inside. There are many birds and beasts, which are easy to bring viruses, which is not conducive to the requirements of closed management of chicken farms.

- The construction of chicken coops.

The construction of chicken coops first needs to follow the principles of reasonable planning. Large-scale chicken farms are built for the purpose of saving labor, so the chicken farms must be built reasonably so that workers can get the tools and equipment they need at work as quickly as possible. The egg house must be placed at the egg outlet of the chicken house, the feed house must be close to the feed tower, and the dryer must be built at the end of the chicken house, so that the manure cleaning machine can directly send the chicken manure to the vicinity of the dryer, etc. Anyway, the most important thing is to facilitate work and reduce the amount of labor of workers, so as to achieve the purpose of saving labor.

- The internal structure of the chicken house.

The interior of a large chicken farm is different from an ordinary chicken farm. Ordinary chicken farms should leave a manure passage of about 2 meters to facilitate the work of the cycloidal needle heavy manure cleaner. But large chicken farms must use flat belt manure cleaners, also known as crawler manure cleaners and conveyor belt manure cleaners. The names are different, but the things are the same. The flat belt manure cleaner does not need a manure passage, only a horizontal manure passage is dug at the tail of the manure cleaner, so that the manure cleaner can directly take the chicken manure out.

The chicken house does not need to keep windows, ventilation and light are given artificially, but the air inlets need to be left, and the air inlets should be set according to the number of chickens and the power of the fans. The requirements for fans and water curtains are relatively high, and it is necessary to accurately calculate the number of fans and the area of the water curtain. Because large chicken farms have a very large investment, they can save money if they don't have the necessary expenses.

- Construction of the outside of the chicken coop

The walls of the chicken house are built with bricks, which can be weaker for hot ones, but mainly in areas where it is cold all year round. Because the weather is cold in winter, the walls must be installed with insulation layer to keep warm in winter.

A steel structure is used on the top of the chicken house to try to make the chicken house clean and hygienic to prevent the infiltration of viruses.

For the manure outlet of the manure cleaner at the tail of the chicken house, it is necessary to dig a manure conveying channel for oblique manure removal, which is convenient for conveying the chicken manure to the dryer or directly loading the truck.

- Management of the chicken coop

The chicken coops are all managed in a fully enclosed management mode. The people entering and leaving the chicken coop must be strictly controlled. The people entering and leaving the chicken coop must be disinfected. People who are not disinfected must enter the chicken coop. After the batch of chickens is over, full disinfection will be carried out. At work, there must be professional technicians, and technicians play a vital role in the chicken farm.

More...

Nutrition control measures of broiler cages in hot season

%AM, %12 %403 %2021 %08:%OctBroiler chickens do not have sweat glands, so farmers who use broiler chicken cages to raise chickens must pay attention to reasonable cooling and nutritional control of the chicken house in the hot season.

In order to reduce the adverse effects of high temperature on broilers, it can be adjusted from the perspective of nutrition to achieve good results. First, we must adjust the formula of broiler rations. In the hot season, the price of broiler chickens decreases, the feed intake decreases, and the nutrient intake is insufficient. This is to increase the nutrient concentration in the diet to ensure that the broiler chickens receive sufficient nutrients. However, it should be noted that some farms believe that simply increasing the protein concentration in the diet and feeding broiler chickens with high-protein feed can meet the nutritional needs of broiler growth and development, but this is not the case. This is because the broiler will further reduce the feed intake of the broiler after ingesting the high-protein feed. In severe cases, it will even refuse to eat, resulting in insufficient energy intake of the broiler, which will inevitably affect the growth and weight gain of the broiler. In the hot season, the energy level in the diet can be appropriately increased, while the protein level in the diet can be reduced. At this time, broilers will eat more feed in order to meet the demand for protein, and at the same time, they will take in sufficient energy. The weight will increase and the feeding effect will be better.

Adjust the number of feedings and feeding time per day. Broiler chickens have poor appetite when the temperature is too high. For this reason, you can adjust the feeding time to avoid feeding the chickens during the high temperature period of the day. Try to choose the cooler time of the day to feed the chickens, and you can be earlier in the morning. , Feed the chickens later in the evening to reduce body temperature and improve feed utilization. In addition, allowing broilers to rest during periods of high temperature can increase the daily gain of broilers.

Provide adequate drinking water and increase the amount of cool feed fed. Broilers can effectively cool down by drinking cool drinking water. For this reason, try to provide fresh and cool drinking water to broilers in the hot season. In addition, in the choice of feed, the amount of feed for roots, tubers, melons and fruits can be increased, which can reduce temperature and reduce heat stress.

Regulate the acid-base balance in the body. In the hot season, broiler chickens are prone to adverse reactions of respiratory poisoning, and the acid-base balance in the body is destroyed, thereby causing physiological function disorders. For this reason, it is necessary to adjust the acid-base balance in the broilers.

The above is the nutritional control of broiler chickens in hot weather shared by poultry chicken equipment manufacturers. I hope that the above content can help farmers.

The cage supplier will tell you how to manage the laying hens

%AM, %11 %400 %2021 %08:%OctWith the rapid development of the chicken industry, the market has put forward higher and higher requirements for the output and quality of eggs, so the breeding of laying hens has become the key to egg production. Next, in combination with the actual production, the chicken cage supplier will talk about the management of the breeding eggs.

Although the hens who have just started to lay are sexually mature and begin to lay eggs, the body has not yet fully developed. The body weight is still increasing at the age of 18 weeks. The growth and development basically stops at the age of 40 weeks, and the weight gain is very small. After 40 weeks of age Most weight gain is fat accumulation. Laying hens of different ages have different utilization of nutrients. When the hens just reach sexual maturity (17-18 weeks of age), mature ovaries release estrogen, which significantly increases the hen's calcium storage capacity, and starts to lay to the peak of laying. During the period, the chicken's ability to digest and absorb nutrients is enhanced, and the feed intake continues to increase, until the late stage of laying, the digestion and absorption capacity is weakened, and the fat deposition capacity is enhanced.

In the first 3 to 5 days before the transfer, prepare and disinfect the laying hen house, and do the immunization and repair work of the reserve hens before transfer. Regarding the timing of transfer, due to the results of recent years of breeding, the age of chickens has been brought forward. The transfer should be carried out at 16 weeks of age. When the chickens are between 17 and 18 weeks of age and their body weight reaches the standard, they will be replaced immediately. Egg feed can increase the calcium reserves in the body and allow the young hens to store sufficient nutrition and physical strength in the body before delivery.

Practice has proved that according to body weight and sexual development, changing the egg-laying feed earlier is beneficial to future egg laying. Using calcium feed too late will cause paralysis and produce soft-shelled eggs. The start of labor is a major turning point in the life of a young hen, and it is a great stress. During this period of time, the reproductive system of the young hen matures rapidly, and the weight of puberty still needs to increase continuously, roughly 400~500g. The egg weight gradually increases, the egg production rate rises rapidly, and consumes most of the hen's physical strength. Therefore, it is necessary to reduce further interference to the chickens from the outside as much as possible, reduce various stresses, and provide the chickens with a peaceful and stable living environment , And ensure that the nutritional needs of chickens are met.

The light management during the laying period should be consistent with the light during the rearing period. Raised in an open chicken house, if the transfer group is in the season of gradual increase in natural light, and the chickens fully adopt natural light during the rearing period, the light hours have reached 10h or more when the group is transferred, and there is no need to supplement it when transferring to a layer With artificial lighting, when the natural light starts to become shorter, the progress of adding artificial lighting to provide artificial lighting subsidies increases every week.