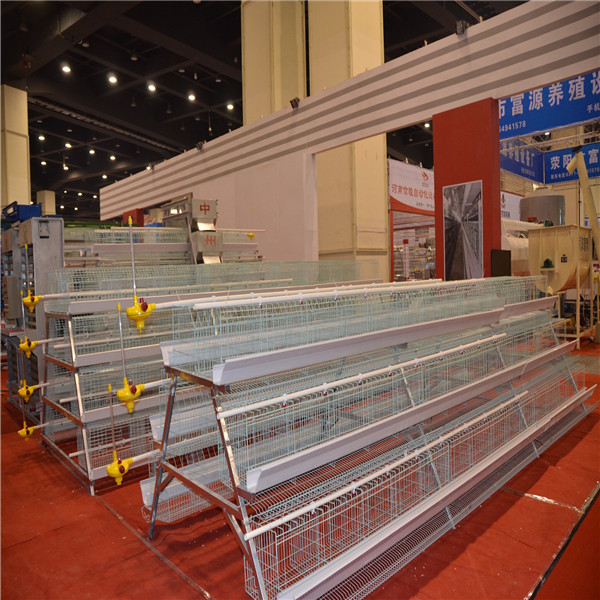

The chicken battery cages with reasonable structure and excellent quality has a service life of 15-20 years. It can provide a relatively comfortable living environment for chickens and ensure the normal potential of chickens. However, for chicken cages with poor structure and poor quality, either the chicken will deform and the solder joint will crack as soon as it is put into the cage, or the chicken will be stuck continuously, which will make the chicken in a state of stress for a long time, make it difficult to give full play to the normal production performance, and cause huge losses.

It can be seen that the quality of layer cages is directly related to the economic benefits of the chicken industry. Whether it is cage manufacturers, chicken farm technicians, or general individual chicken farmers, they should attach great importance to this. Therefore, it is very important to choose a good quality layer cages.

The production materials of chicken cages require cold drawn steel wires. Inferior steel quality is generally manifested by low steel wire hardness and poor elasticity, which reduces the overall strength of the chicken cage and is easy to deform. For the finished product that has been welded, the quality of the steel wire can be identified from the following aspects:

High-quality steel wire has high hardness and strong elasticity. Use your fingers to pinch the two adjacent steel wires on the chicken cage sheet where the distance between the welding points is large. You should clearly feel the elasticity of the steel wire. When the force is moderate, the slight bending caused by the pinching can basically reset itself. , The steel base wood will not be deformed if you use light force. If the steel has a low hardness and poor elasticity, it will produce irreversible deformation if the adjacent steel wires are pinched with light force by hand. If the steel wire is severely bent without resetting with moderate force, the steel wire feels almost inelastic, so pick up the cage to make it When it fell on the concrete floor, his voice was short and muffled.

The cage plate made of high-quality steel wire has a loud and high sound on the ground, and the reverberation is long. The steel wire with extremely poor hardness will produce small wavy bends when straightened, which is very obvious from the eye, and the high-quality chicken cage steel wire will never appear such bends. A chicken cage welded with a low-hardness steel wire, even if the solder joints are firm, the chickens will be overwhelmed and bowed severely after being basketed, which can cause water and trough deformation or breakage, which is not only inconvenient for management, but even Make it difficult for chickens to eat and drink