The future of layer chicken cages in Ghana

%AM, %14 %169 %2023 %03:%SepGhana chicken farming industry is moving in a more modern and sustainable direction, with layer chicken cages in Ghana being seen as a key factor in increasing production efficiency and improving chicken raising conditions.

On the one hand, layer chicken cages in Ghana have been a huge success in poultry farming in Ghana. They provide more production space, reducing the need for chicken housing and allowing farmers to manage their chickens more efficiently. This not only increases chicken and egg production, but also helps increase farmers’ income.

On the other hand, layer chicken cages in Ghana improve sanitation and waste management. They make manure and waste easier to dispose of, reducing negative impact on the environment. This helps reduce pollution, protect ecosystems, and make chicken farming more sustainable.

However, there are some challenges that need to be overcome to realize the full potential of layer chicken cages in Ghana. First, investment costs may pose a barrier to some small farmers, thus requiring support from government and agricultural institutions. Secondly, training is key to ensure farmers understand how to use the equipment effectively.

Ghanaian farmers benefit from sustainable poultry farming with battery chicken cages

%AM, %12 %456 %2023 %09:%SepGhanaian farmers benefit from sustainable poultry farming with battery chicken cages

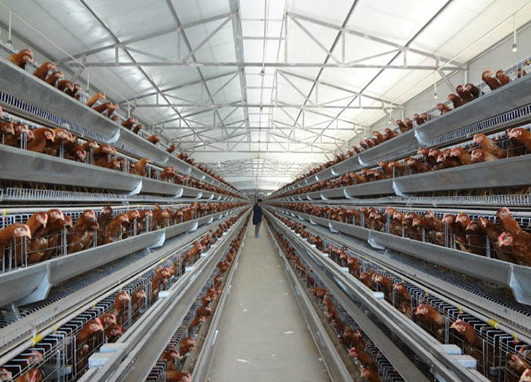

Ghana's poultry farming industry is undergoing a revolutionary change, driven by modern poultry farming equipment, the most eye-catching of which is the stacked chicken cage. The rise of this technology is already delivering impressive results, which bodes well for farmers and breeders in Ghana for sustainable development.

In traditional poultry farming, the problem of land occupation has always been a headache. However, Ghana has limited land resources and faces pressures from urbanization and competition for agricultural land. This has forced farmers to find more efficient farming methods to meet growing demand.

The advent of battery chicken cages in Ghana has changed the rules of the game. The core of this equipment are multi-layer vertical battery chicken cages that can be flexibly stacked together to maximize land utilization. Compared with traditional cage raising methods, battery chicken cages allow farms to significantly increase egg production and occupy less land.

But that's not the only benefit. battery chicken cages are often equipped with automated feed and water systems to ensure that the chickens receive adequate food and water. This kind of automation helps reduce feed waste, improve resource usage efficiency, and reduce breeding costs. At the same time, the sanitary conditions of these chicken cages are easier to manage, reducing sanitary problems that may occur under traditional breeding methods.

Moreover, the design of battery chicken cages in Ghana helps separate eggs and feces, reducing the risk of egg contamination. This means that the eggs produced are cleaner, safer and more in line with high-quality standards, further improving market competitiveness.

In Ghana, more and more farmers are beginning to realize the potential of stacked chicken cages and actively investing in this modern farming method. As demand for high-quality eggs continues to increase, this sustainable farming method provides farmers with the opportunity to achieve profitability. Additionally, it contributes to the sustainability of the agricultural sector, reducing resource waste and environmental pollution.

Overall, battery chicken cages in Ghana represent the future of poultry farming in Ghana. This technology has been successfully used on many farms, improving yields and benefits and reducing environmental burdens. As more farmers adopt this technology, Ghana's poultry farming industry will move in a more sustainable and prosperous direction, while providing more high-quality eggs to the market.

The right battery chicken cages selection will be the cornerstone of success

%AM, %16 %175 %2023 %03:%AugIn the field of farming, the choice of poultry equipment is critical to the health and production of flocks. Whether it is large-scale commercial farming or family chicken raising, how to provide a suitable living environment is a problem that farmers must seriously consider. Especially when you plan to raise a large number of chickens, especially 10,000 chickens, the choice of battery chicken cages will directly affect the success or failure of the entire chicken raising plan. After all, raising chickens is not only an industry, but also a career that requires careful planning and management.

In this farming plan full of challenges and opportunities, the role of battery chicken cages is like a cornerstone. A suitable commercial chicken cage can not only provide a comfortable living environment, but also optimize the feeding process, reduce the risk of disease transmission, and improve the production efficiency of chickens. From the perspective of chickens, the design of chicken cages should fully consider the behavior of chickens and provide enough space for them to move, eat and rest. From the perspective of farmers, reasonable chicken cage design can reduce the burden of management and make the breeding process more efficient and sustainable.

However, raising 10,000 chickens is not as simple as buying battery chicken cages. In addition to the price of the battery chicken cage, you also need to consider a series of costs associated with it, such as transportation, installation, maintenance and upkeep costs. These additional costs occupy an important position in the whole breeding process. For example, the transportation and installation of chicken coops requires a professional team and equipment to ensure that the chicken coops can arrive safely and be put into use. In addition, the daily maintenance and regular maintenance of chicken coops is a key part of ensuring the health and production of chicken flocks.

In addition, the benefits of purchasing A type layer cages are not limited to increased production. A comfortable housing environment can reduce stress and competition among birds, reducing the risk of disease transmission, thereby reducing the use of veterinary drugs. This is not only in line with the concept of environmental protection and health, but also helps to improve the quality of eggs, meat and poultry, and meet consumers' needs for food safety and quality.

To sum up, choosing to buy A-type layer cages to raise 10,000 chickens is a process of comprehensive consideration. From an economic point of view, this involves the cost of purchasing the coop itself, as well as the transportation, installation, maintenance and upkeep costs associated with it. From a production point of view, the selection of suitable battery chicken cages will directly affect the efficiency and sustainability of raising chickens. In the chicken business, carefully choosing the right chicken cage is laying a solid foundation for future success.

Increase Your Profits with Battery Broiler Cages

%AM, %08 %182 %2023 %03:%AugThe broiler cage system, as a modern and efficient broiler breeding method, is leading the innovation wave of the chicken industry. More and more farmers choose the stacked chicken cage system to increase production and economic benefits and achieve sustainable development of poultry farming. In this article, we'll take an in-depth look at broiler cage systems from several key angles, showing you how battery broiler cages can bring more profit and success to your chicken business.

- The broiler cage significantly improves the yield and economic benefits of broiler chickens by optimizing the stocking density and scientific management. First, stacked chicken cages allow farmers to put more broilers in a limited space. Maximizing the use of chicken farms has resulted in a substantial increase in production. Second, the use of centralized management and automation facilities. The feeding cost and labor input are effectively reduced, thereby creating higher economic benefits for farmers.

The advantages of battery broiler cages enable farmers to meet market demand in a more efficient manner and achieve considerable profit growth. In the increasingly competitive chicken industry, choosing a broiler cage system is a wise choice for you to increase production and obtain greater economic returns.

- The broiler cage system plays an important role in optimizing management and realizing convenient operation. The centralized feeding mode enables farmers to manage chicken flocks more conveniently, thus effectively reducing management costs and manpower input. Chicken farmers can more easily monitor the diet, growth and health of broilers, and take corresponding measures in time to ensure the good growth of the flock.

At the same time, the widely used automation facilities in the broiler cage system, such as automatic feeding and automatic defecation systems, further reduce the labor burden of farmers. These automated facilities not only improve the efficiency of raising chickens, but also ensure the health and welfare of the flock. Through optimized management and convenient operation, the broiler cage system provides farmers with more efficient and reliable solutions for raising chickens, making the chicken industry more scientific, standardized and sustainable.

- The battery broilercagesplays an active role in sustainability and environmental protection. First of all, the system optimizes the stocking density and concentrates broiler chickens in a limited space, effectively reducing the occupation of land resources and helping to protect the natural ecological environment. Secondly, the broiler cage system can concentrate on the treatment of chicken manure and convert it into organic fertilizer, which reduces the pollution of excrement to the environment and realizes recycling.

In addition, the battery broiler cages can effectively reduce the competition and injury among chickens, provide a safe and comfortable growth environment, and help improve the survival rate and health level of chickens. The environmental protection concept of the broiler cage system is in line with the modern society's pursuit of green farming, and will help promote the development of the chicken industry in a more environmentally friendly and sustainable direction. In the context of limited global resources, choosing a broiler cage system is an important measure to actively respond to the call for environmental protection and achieve sustainable development of the chicken industry.

Battery broiler cages, as an efficient, economical and environmentally friendly farming method, brings many advantages to your chicken industry. We hope that the information provided in this article will help you gain a more comprehensive understanding of broiler cage systems and lead to more profits and success. If you have any questions about broiler cages or purchase intention, please feel free to contact us, we will be happy to provide you with more detailed information and support.

What Is To Be Considered In Buy Chicken Layer Cage?

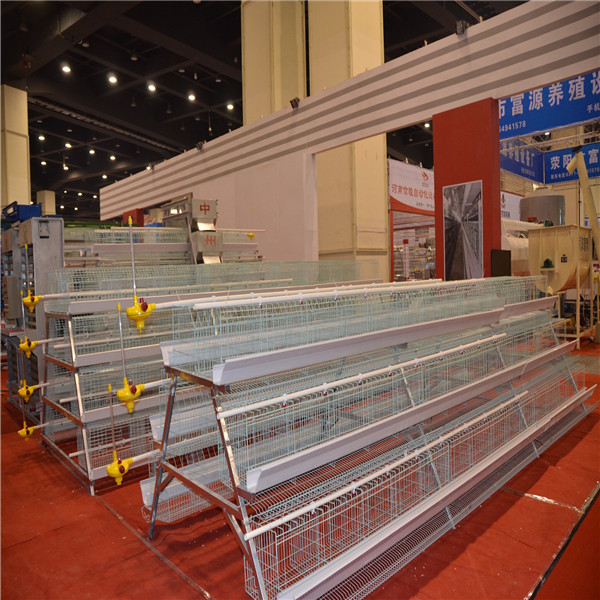

%AM, %27 %435 %2023 %09:%JulAs a farmer, you know the keys to success in the chicken industry. Among them, choosing a suitable laying hen cage is an important link to ensure the health of chickens and improve egg production efficiency. When buy layer cages, you should carefully consider the following detailed design elements to lay a solid foundation for your chicken business.

Chicken layer cage material:

a. High-quality materials such as high-strength galvanized steel have good corrosion resistance, can resist the corrosion of wet environment and feces, and prolong the service life of the chicken cage.

b. The stability and strength of the material can withstand the movement of the chicken and the weight of the egg, preventing deformation or damage to the chicken cage.

Chicken battery cage space:

a. Make sure that the size and space layout of the chicken cages can provide enough room for movement, and the birds will not be crowded and stressed, which will help maintain good production performance.

b. Consider the internal layout of the chicken house and arrange the spacing between the chicken cages reasonably to ensure that the chickens have enough freedom when moving and foraging.

The angle of inclination at the bottom of the layer cage:

a. The moderate inclination angle of the bottom is to facilitate the roll out and collection of eggs, and reduce the breakage and dirt of eggs.

b. The angle of inclination should be designed according to the size of the eggs and the laying posture to ensure that the eggs can roll out of the cage smoothly without staying at the bottom.

The service life of the chicken cage:

a. Understand the design life and service life of chicken cages to ensure that your investment can be effective in the long run.

b. Long-life chicken coops can reduce the frequency of equipment replacement, save maintenance costs and improve economic benefits.

Safe and easy to clean:

a. Ensure that cages are designed to meet safety standards and avoid sharp edges or corrosive parts to prevent bird injury or infection.

b. Design chicken cages that are easy to clean to reduce the growth of bacteria and pathogens in the feeding environment, which is conducive to the health management of chickens.

To sum up, when buying layer chicken cages as a farmer, you should carefully consider the material, space layout, bottom inclination angle, service life, safety and ease of cleaning of the chicken cage. Choosing a reasonable laying hen cage design can help improve breeding efficiency and economic benefits, and protect the health and welfare of chickens. It is a wise decision to fully communicate with professional poultry equipment manufacturers and choose high-quality layer cages that meet the needs of your farm.

How to reduce dust for modern chicken houses?

%AM, %02 %441 %2022 %09:%AugOne of the most troublesome problems for poultry farmers should be the hygiene of the chicken houses. The environment of chicken farms is related to the growth of chickens, and the inevitable problem in chicken farms is dust. The dust in the chicken farm mainly comes from the dust in the poultry farm cages, as well as the fallen feathers and feed powder. These dusts not only affect the staff in the chicken house, but also have a great impact on the health of the flock. So how to reduce dust in the chicken houses?

Ways to Reduce House Dust

Water the ground. The most dusty place in the coop is the ground. Due to the high breeding density in the chicken house, the feces, chicken feathers, soil and other debris of the chicken house are on the ground. Clean and maintain the sanitation of the chicken house in time.

Reduce breeding density. The higher the breeding density, the more dust. In order to effectively reduce the dust in the chicken house, we can appropriately reduce the density and also reduce the dust content in the chicken house. After all, there is a lot of dust coming out of chickens, such as feathers, feed meal, etc. However, this also takes into account the overall farming efficiency.

Ensure good ventilation. Good ventilation can promote the air circulation in the house and drive the dust away from the house. Poultry farmers can purchase automated environmental control equipment in battery cage systems - fans and pads. It can effectively ventilate the chicken house.

Clean the chicken house often. Dust doesn't appear all at once, it builds up over time, so dust reduction is a long-term continuous process. In the process of raising chickens, it is necessary not only to clean the chicken coop frequently, but also to clean the outside environment frequently. With less dust outside, the dust in the house will naturally decrease.

It is very important to purify the air in the chicken house in the current chicken industry, especially for some modern chicken houses, because most diseases of chickens are transmitted through the air. The battery cage manufacturers reminds everyone to pay attention to the hygiene of the chicken souses.

What are the challenges that have to be overcome in raising chickens in Uganda?

%AM, %01 %448 %2022 %09:%Aug

The development of poultry farming projects in Uganda is very promising. But there will also be some challenges. Today, battery cage manufacturers will analyze the challenges faced by the development of poultry farming. Hope to be able to give some guidance to poultry farming friends.

- Space requirements in the reduction of land area. If you opt for free-range chickens, you don't need much space, but not as much for poultry. If you're raising chickens in buy battery chicken cages and you happen to have thousands of them, this is a great way to increase the utilization of your chicken farm.

- Diseases and Parasites - Diseases and parasites are a major problem in poultry farming. Bird deaths and reduced egg production due to disease outbreaks impact poultry farming. Information on vaccination, treatment and feeding (will be your key. This will protect against death and low yields.

- Most farmers do not have a specific market where they can sell their eggs or birds. Also, most are sold to middlemen at lower prices, affecting profitability. Still, the low competition for rearing with battery cage systems means higher profitability for those in it. Today, you can find a ready market through local breeding groups, social media, testimonials and internet sources.

- Financial issues and start-up capital - We recently discussed the cost of setting up a poultry farm in Uganda, and the cost can be overcome. However, if you are just starting out, finding funds from a bank or other financial source can be difficult. You might consider starting small and growing your flock slowly and slowly. This is the main problem affecting most farmers. Most farmers do not have the huge sums of money to start the project and have not purchased poultry equipment, so they cannot raise poultry successfully.

- Battery chicken cages for salein Uganda. Buying an affordable battery cage is part of the success of your poultry farming project. Not only save space, save money, save manpower. A high-quality chicken cages can be used for 20 years. Safeguard your poultry farming project.

Comprehensive and practical chicken raising technical knowledge points!

%AM, %29 %467 %2022 %10:%JulPoultry farming projects are still very popular today. How to effectively carry out poultry farming projects. The battery cage manufacturers will introduce comprehensive skills to you today.

The selection points of chicken farm site

The chicken farm site should be selected in a relatively remote living area and a place that can be reached by vehicles, a high, dry, well-drained place, and the site should have water and power sources.

The selection of chicken breeds

The selection of chicken breeds should be determined according to the adaptability and market demand of chickens in the garden. Generally, the local thoroughbred chickens with strong adaptability, strong disease resistance, strong foraging ability, rough feeding resistance, tender meat, and delicious taste are selected or hybrid chickens with more than 75% of the local native chicken blood. And to consider the market demand, choose a marketable breed, it is best to choose an excellent breed of native chickens cultivated by regular units.

From the perspective of production performance, chickens can be divided into layers, broilers, and eggs and meat. The economic benefits of broilers are high. It can be slaughtered in 45 days from rearing time. This is incomparable to other animals. Seven or eight crops can be raised within a year.

Poultry equipment needed for raising chickens

Simple chicken farms need basic poultry equipment such as chicken battery cages for sale, drinking water equipment, feeding equipment, and manure cleaning equipment. If it is a large-scale breeding, in order to improve work efficiency, more comprehensive mechanized equipment can be considered.

The problems that need to be paid attention to in the management of chicken feeding

- The management density of chicken farms should be moderate. The stocking density should be moderate. Each henin poultry laying cages should have enough troughs and drinking fountains, and the location should be appropriate. The chickens should be regularly provided clean and the water temperature should be suitable for drinking. Feeding and management of laying hens uses a chain feeder for feeding, which should be fed regularly every day, and attention should be paid to improving the nutritional level of the diet in time during the rising stage of egg production.

- To reduce the contamination of eggs, it is also necessary to minimize the contamination and damage of eggs. Environmental conditions should be as stable or gradual as possible. The closed chicken house should turn on and off the lights on time, so that the daily light time can be supplemented as required. In addition, it is necessary to adjust the ventilation volume according to the seasons to make the temperature in the house more suitable.

- Be aware of weather regulations that suddenly turn into severe weather in open houses: the impact on the flock. Feeding and management of laying hens Regardless of the type of chicken house, appropriate insulation or cooling measures should be taken to prevent cold and heatstroke, and to prevent the relative humidity and concentration of harmful gases in the house from exceeding the limit indicators, so that the chickens can maintain high and stable egg production.

More...

How to raise chickens using chicken cages in Uganda?

%AM, %22 %422 %2022 %09:%JulChickens are raised using wire-welded chicken cages in Uganda. Different types of battery cages are designed according to the breed, sex and age of the chickens. There are chicken cages, brooding cages, layer battery cages, breeder cages and rooster cages, etc., which are currently the most important ways of raising chickens in the world.

Describe the advantages of battery cage system

- Improve the stocking density. The stocking density of the three-dimensional chicken cage is more than 3 times that of the horizontal stocking density. The laying hens can be raised more than 17 per square meter.

- Save the feed. Putting the chickens in thepoultrycage reduces the amount of exercise, reduces energy consumption, and reduces the waste of materials.

- Easy to install, simple to operate, strong and ventilated, suitable for open, semi-open and open houses.

- Chickens do not come into contact with feces, which is conducive to the prevention of chickens.

- The eggs are cleaner and can eliminate eggs outside the nest. 6. Compared with the ground, it saves 75% of the feeding area and improves the egg production rate.

Feeding and management methods using poultry cages for sale in Uganda

A well-managed house can save feed and avoid feed waste. And maximize the conversion of input feed into chicken growth. A well-managed chicken house will reduce the incidence of chicken diseases, which can save both the cost of vaccine purchases and the cost of routine preventive and therapeutic drugs.

Increase ventilation every day, pay attention to maintaining the humidity of the chicken house, and maintain proper humidity measures. Generally, the limit for high humidity is higher than 75%, and the limit for low humidity is lower than 40%. When the humidity is too high, ventilation should be strengthened to remove moisture. Main methods: ground spraying, aerial spraying,

How to choose chicken feed with battery cage for layer

Feed is the foundation of raising chickens and the key factor for the success or failure of raising chickens. In general, the cost of feed accounts for 70% to 80% of the cost of raising chickens. So how to choose, use and develop feed reasonably, improve the rate of return of feed, and reduce the rate of feed consumption plays a decisive role in increasing the cost of raising chickens.

Economics of raising chickens. Common feed for chicken cages can be roughly divided into energy feed, protein feed, mineral feed, vitamin feed and feed additives.

The role of poultry farming equipment in Nigeria

%AM, %21 %425 %2022 %09:%JulPoultry farming equipment in Nigeria is widely acclaimed. The utility model has the advantages of simple structure and convenient operation, which greatly saves labor. At the same time, the excrement is cleaned in a centralized manner, which solves the problem of serious environmental pollution of the whole chicken house, and has great practical value.

- Easy to manage. Now the scale of the farm is large, and the caged method is convenient for the management of laying hens and easy to operate.

- Diagnose and treat the condition of laying hens in time. The caged chickens facilitate the farmers to diagnose and treat the laying hens in a timely manner when they are sick, and at the same time reduce the difficulty of diagnosis and treatment, and the laying hens are in good physical condition.

- It is convenient to feed. The chicken cage for sale in Nigeria is convenient for the farmers to feed the laying hens, reducing the workload and improving the work efficiency.

- Save labor costs. The use of poultry farming equipment has allowed the development of intensive poultry farming projects. The fantasy of 2 people managing 20,000 birds becomes a reality. Poultry Farming Friends is no longer hiring managers. You can manage the chicken farm yourself.

- 5. The utilization rate of the chicken house is high. The number of battery cages installed in the chicken farmis more than 3 times more than that of deep litter-raised chickens.

6.The commercial battery cages is widely used in large-scale farming by farmers in tropical countries such as Africa, Southeast Asia, and South Asia.