What is the Rearing Mode for Broilers on the Floor?

%AM, %15 %096 %2018 %01:%JunGround-level broiler chickens have lower requirements for broiler houses, laying 5~10cm thick litter on the ground in the house, cleaning and replacing them on a regular basis, or replacing them with a 15cm thick litter and one feeding cycle. It is best to use a concrete structure for the flat hen house; in the area where the soil is dry porous sandy soil, mud land can also be used as the house ground.

The advantages of ground leveling are simple equipment, low cost, and low incidence. The disadvantage is that it requires a large amount of litter, covers an area of more, the used litter is difficult to handle, and often become a source of infection, prone to chicken diseases in your poultry farming equipment.

How to Reduce the Poultry Equipment Cost of Raising Chickens?

%AM, %06 %111 %2018 %01:%JunIn the process of raising chickens by farmers, the number of cultured animals is relatively large, and some artificial and chicken-breeding equipment are also needed. Therefore, the cost of raising chickens is relatively high, but the use of equipment is relatively long. The overall cost is still relatively low, in addition to the artificial cost of these equipment, chicken feed is a relatively high expenditure in chicken costs, then how to keep chickens on the premise of ensuring the health of chickens down the cost of breeding?

Installation of Chicken Feeder Requirements for Chicken Houses

%AM, %29 %387 %2018 %08:%MayThe Reason That Farmers Choose Automatic Poultry Feeders

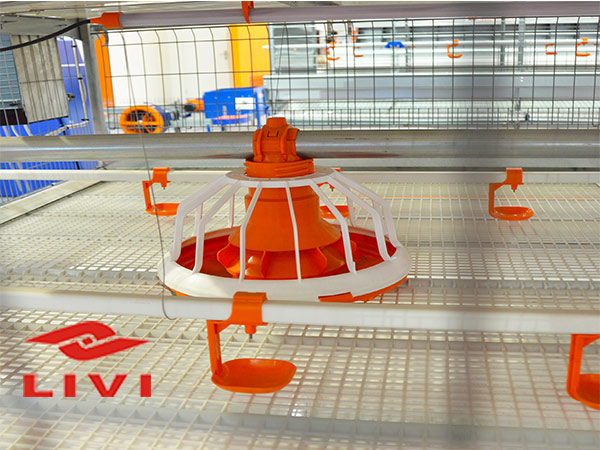

In order to reduce the cost of hiring labor and reduce the labor intensity, many farmers now choose some more automated chicken-raising equipment for chicken-raising work, especially for chickens, and large-scale chicken farms. It is a time-consuming and labor-intensive process to feed a large quantity of food. If feeding artificially does not guarantee the even feeding of each chicken, many farmers would like to buy feeders for feeding chickens for feeding.

What are the requirements to use automatic poultry feeders?

However, not all chicken farms can meet the requirements for installing and using chicken feeders. The installation and use of feeders requires certain requirements for the environment of the poultry house. What are the requirements?However, not all chicken farms can meet the requirements for installing and using chicken feeders. The installation and use of feeders requires certain requirements for the environment of the poultry house.

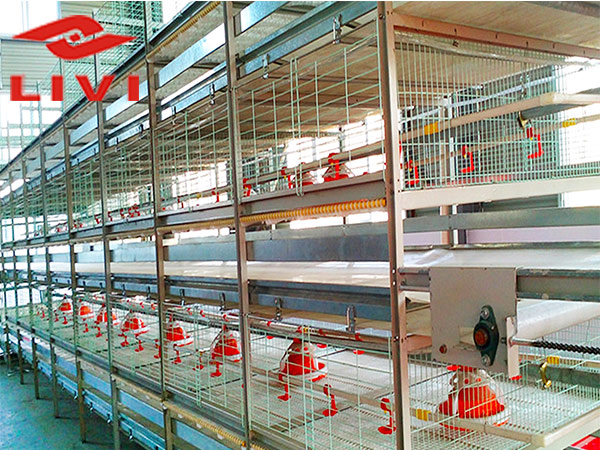

First of all, if farmers want to use feeders for aquaculture, then their own way of raising chickens is a cage mode, and only a chicken house with multi-layer cages can be installed and used.

The second point is the height of the farmer's coop. Since it must be a multi-layer chicken cage, the feeder will naturally raise the height of the coop to fully feed the chickens. Generally speaking, The height of the house inside the house is required to be 2.6 meters or more, and the length of the cage can be within 100 meters.

With the continuous promotion of intensive chickens, there are more and more users who use cages to raise chickens. Most of the caged chicken houses are also in compliance with the requirements. Before purchasing automatic feeders, farmers are You should understand your pasture situation and you can choose more suitable feeding equipment according to your own farm.

How Many Types Of Chicken Cages?

%AM, %16 %133 %2018 %02:%AprThe most important chicken-raising facility in a chicken farm is a chicken cage. Chicken cages can be divided into chicken cages, semi-ladder cages, stacked chicken cages, breeding cages, broiler cages, laying cages, etc. These chicken cages have their own characteristics according to the different chickens and the needs of breeding. And meet the corresponding basic needs, Xiao Bian here and everyone introduced.The most important chicken-raising facility in a chicken farm is a chicken cage. Chicken cages can be divided into chicken cages, semi-ladder cages, stacked chicken cages, breeding cages, broiler cages, laying cages, etc. These chicken cages have their own characteristics according to the different chickens and the needs of breeding. And meet the corresponding basic needs, we can provide you the types of chiken cages.

Chicken cage equipment is the main body of chicken equipment. Its configuration and structural parameters determine the stocking density and determine the requirements for the selection of equipment such as excrement, drinking water, and feed, and the requirements for environmental control equipment. Chicken cage equipment can be divided into groups.

Chicken cage equipment is the main body of chicken equipment. Its configuration and structural parameters determine the stocking density and determine the requirements for the selection of equipment such as excrement, drinking water, and feed, and the requirements for environmental control equipment. Chicken cage equipment can be divided into full-stepped, semi-stepped, laminated, compound-type and peace-placed in accordance with the combination; according to the geometric size can be divided into deep cage and shallow cage; according to the type of chicken is divided into layer cage, Broiler cages and breeding cages; According to the weight of the chickens, they are divided into light-type cages, medium-type layer cages and meat-type cages.

1. Full-step (A-type )Chicken cage

The fully stepped cage is generally 2 or 3 layers with no overlap or overlap between layers. It have many advantages. Firstly, each floor cage open area, good ventilation. Uniform light; Secondly, cleaning operation is relatively simple; Thirdly,structure is relatively simple, easy maintenance; Last but not least, poultry manure removal system is convenient for manual operation. The disadvantage is that the stocking density is low, generally 10-12/m2. The three-step full-step chicken cage and breeder two-step full-step artificial insemination of laying hens is the most commonly used combination of chicken cages in China.

2. Half-step cages

The semi-stepped cage is partially overlapped between the upper and lower layers, and the upper and lower overlapping parts are provided with a dung-proof plate. The dung-proof plate is installed at an angle and the excrement slides into a human pit. The word density 15-17/square root is higher than the full ladder, but lower than the cascade. Due to the obstruction of the dung blankets, the ventilation effect is slightly worse than the full step.

3. Stacked chicken cages(H-TYPE chicken cage system)

There is a complete overlap between the upper and lower layers of the stacked chicken cages, and the chicken wastes are carried by the conveyor belt between the layers. Its advantages are high house feeding density, three-layer full-overlap breeding density of 16-18/m2, and four-layer full-overlaying density of 18-20/m2. The number of stacked chicken cages can reach 8 or more layers, which is suitable for chicken farms with a high degree of mechanization. The rearing density can be greatly increased, the floor area of the farm can be reduced, and the production efficiency of the rearing staff can be improved. However, the requirements for the building, ventilation equipment, and cleaning equipment are relatively high. The egg farms in developed countries now generally use this form. Only a handful of mechanized chicken farms in China use this technology.

What temperature should be in a cage?(Some tips to make your laying hens healthy)

%AM, %04 %358 %2018 %07:%AprWhat temperature should be in a cage?

The temperature is closely related to the growth of the chicken and the egg laying of the laying hen hens. What temperature should be in the cage? For beginners of poultry farm in this matter, we'll see!

Temperature control in the chicken coop

Creating the optimal temperature for chickens is especially important, otherwise it's easy for them to get sick. If they are cold, they get bored and squeak; if it's hot, they spread out all over the cage, open the beak, drink a lot. At night, the chickens are without movement, and therefore they need more heat than during the day. It is necessary to monitor the air temperature not only in the room, but also in the area of the bird, that is, in the cage equipment. Recommended temperature, humidity and air exchange in poultry houses for growing maintenance young hen eggs are given.

What temperature should be in the cage for laying in winter? The one who keeps chickens at home knows that in the summer the hens carry eggs almost every day. But in the winter egg production decreases to one egg per week, and even completely disappears. And so it is important to find out what temperature it is necessary to maintain the laying hens in the cages.

Optimal conditions for keeping laying hens in cages in winter:

1. The temperature in the cage in winter should be within the range of 12° С to 18 ° С. A sharp decrease or increase is fraught with a significant decrease in the number of eggs. If the chickens survive the winter in the southern regions without an additional source of heating, then in the temperate zone, and, especially, in the north, lamps for heating the coop may be needed.

2. It is recommended to keep the relative humidity at the level of 60-80%. The indicator is maintained using a ventilation system, preferably with adjustable valves. The air of the chicken coop in winter should be fresh, but without drafts.

3. The lighting of the hen house during the day must last at least 14 hours. If there is enough natural light in the summer, then in winter it is not enough. Without electricity, not do. It is recommended to conduct communications in advance, and switches can be provided with timers for convenience. Lamps are best to choose luminescent.

We recommend that you should control the temperature of the chicken coop in winter and, if necessary, include additional heating. If conditions permit and there is a desire, buy a microclimate for your poultry factory, just remember, buy equipment for poultry farms from reliable dealers or manufacturers!

Broiler Rearing Chicken Cage System

%AM, %27 %340 %2018 %07:%MarBroiler Chicken Cage System

Broiler battery chicken cage systems are very popular used in poultry rearing equipment industry.

If you want to make your chicken rearing business in full swing and improve the efficiency of breeding, in addition to using scientific breeding methods for poultry breeding process, the most important thing is to choose suitable chicken cage system for breeding. The number of broiler breeders is also increasing in modern poultry rearing manufacturers. Now we will mainly introduce to the farmers the broiler cage equipment needed for broiler breeding.

1. Automatic broiler rearing cages: The selection of cages is particularly important, and farmers need to choose not only good quality cages but also cages of the right size. The broiler cages currently on the market are mainly stacked broiler cages, which can increase the number of farmer breeding and reduce the use of sheds, saving farmers a lot of rental costs. Moreover, when using a broiler cage culture, the activity of broilers can be reduced to promote a rapid increase in body weight.

2. Automatic broiler feeding system: Feeder is the equipment used to feed the flock in the complete set of broiler cage equipment. They manually control the amount of feed each day and the speed at which the equipment travels. This will ensure that the birds' diet will not be overfull or over-starved, and the uniform feeding of the equipment will ensure that each bird's diet will reach a uniform level, thereby ensuring the even growth of the chickens, and also for the later period. The flock enters the market at the same time providing protection.

3. Poultry manure removal system: The broiler breeding process is relatively simple, ensuring that the diet of drinking water is even and sufficient, reducing the occurrence of its disease, then its growth rate will increase. The preparation of the dust collector equipment in the chicken house can promptly transport the chicken manure in the house, so that the breeding of bacteria in the house can be avoided, thereby reducing the infection of the broiler flock diseases and increasing the growth rate of the broiler.

Battery Broiler Chicken cage advantages in Livi Machinery:

1. The mesh of the cage is relatively smooth, which can prevent chickens from infecting the foot.

2. The grid and bottom nets of the caged cages are encrypted and can effectively prevent the paralysis of the anus and fatigue syndromes of laying hens.

3. The galvanized mesh of the caged cage can increase the service life of the cage. Generally, it can be used for 8 or 9 years.

4. The high-density breeding of laying hens will save more land, and it will be conducive to epidemic prevention. It will also reduce the incidence of poultry diseases.

5. The unique door reinforcement design of layer cage can effectively prevent the chicken from wasting and wasting feed when eating. And because the cage door space is increased, it is more convenient for various management of chickens.

Poultry Equipment for Chicken Farming Industry

%AM, %21 %352 %2018 %07:%MarLivi Machinery will provide you the popular professional A-frame layer cages and stacked layer cages and also customize poultry battery chicken cages according to customer’s specifications. It is the good and standard poultry farming team that cast into a perfect poultry farming equipment. For our company has more than 60 senior experts, engineers, technicians of the technical development team, for the purpose of meeting the special requirements of customers products.

Poultry Drinking Machine in Poultry Breeding System

%AM, %10 %091 %2018 %01:%MarPoultry drinking system are primarily designed to supply sufficient clean water for chickens and we are the professional manufacturer of poultry drinking system. It is suitable for various types of chickens, including broilers and layers. With the advantages that the drinking system for poultry is easy to clean and needs little maintenance,so great chicken drinking system is widely used for poultry farming manufacturers.

More...

laying hens' farms use poultry farming automatic equipment in advantage

%AM, %07 %163 %2018 %02:%MarThe poultry farming equipment includes chicken coop, manure removal equipment, egg collecting equipment, feeding equipment,drinking equipment and ventilation ring control equipment. A total is divided into six large, this a few things seem very simple, poultry farming equipment itself is for breeding services, in order to in the process of farming chickens to reduce labor costs, improve work efficiency, increase the breeding benefit.

Automatic Pullet Breeding Equipment For Sale

%AM, %06 %279 %2018 %05:%MarPoultry battery cages devide into two categories-layer baby chick cages and broiler baby chick cages. Livi Machinery is fitted with automatic pullet raising equipment system and battery cages for pullet, which are all equipped with automatic baby chicken feeding system and automatic baby chicken drinking system as well as poultry supplies.