The use of chicken cage farming features

%AM, %13 %302 %2019 %06:%MarWith the continuous development of the times, the way of raising chickens in the chicken industry and the farming ideas of the farmers have been greatly changed and updated. Now the chicken industry is more inclined to adopt chicken breeding equipment to raise chickens. The space of the chicken house is utilized, and then the direction of large-scale farming is realized. The cage culture of chicken breeding equipment has realized the leap of the chicken industry. The characteristics of cage culture using chicken breeding equipment are:

1. Standardization: The use of chicken farming equipment for cage farming, equipment and functions, can achieve a scientific feeding management process; and if the farmers purchase automated chicken equipment, they can also achieve automatic feeding, clearing, quail and other heavy The work, fan curtains and other equipment can ensure the comfort of the chicken house, the chicken cage has sufficient material level, reasonable water level and appropriate density. The superior growth environment improves the survival rate of the chicken, reduces the incidence rate, reduces the residual rate, and improves the chicken. The welfare of the group.

2. Saving: the use of chicken equipment for cage farming can greatly save farmers' demand for land, labor, energy consumption (water, electricity, coal). Now the market demand for egg broilers is increasing, if you want to expand If the number of cultures is increased, the farmers will have to expand the land area if they do not use cage culture. Now the land is expensive and difficult to use. It is easy to increase the number of cage cultures and is easier to manage, which can reduce the user's need for manpower.

3. Large-scale: Farmers adopt cage culture to breed, and the chickens are cultured in cages to achieve scale, and management is convenient. The range of activities of chickens is limited, the physical energy consumption is small, the feed compensation is improved, and the uniformity is better. Moreover, cages can detect sick and weak chickens in time, facilitate timely elimination and treatment, and raise chickens in three dimensions. The chickens do not directly contact the feces, which can significantly reduce the incidence of chickens.

4. Food safety: The use of chicken equipment for cage culture is conducive to disease control and eliminates drug residues. Large-scale production is conducive to traceability of the source and ensure food safety.

5.Environmental safety: Farmers use chicken equipment to clean the manure machine to clear the manure, so that the chicken manure does not fall to the ground, and the manure can be automatically cleared, improve the efficiency, clean the chicken manure in time, the chicken manure is dry, and the chicken is eliminated. A lot of ammonia is used.

In summary, the characteristics of cage culture in poultry feeding equipment can be summarized as: standardized breeding, economical farming, large-scale farming, food safety and environmental protection. It is precisely because these advantages reduce the chicken breeding industry. The risk of raising chickens.

Precautions for layer raising equipment

%AM, %07 %401 %2019 %08:%MarThe use of chicken cages to raise chickens is a popular chicken raising method in the chicken industry. The chicken cages are raised in a multi-layer cage. The breeding density is large and the number is large. It is very popular among farmers, using chicken cages to raise chickens, and which are Need to pay attention to the chickens to pay attention to the matter, only pay attention to all aspects of feeding points, scientific and reasonable breeding can be able to raise the higher yield of the chickens, the following authors to tell the majority of farmers to use the chicken cage in spring Chicken's precautions.

Do you know what to pay attention to when using layer raising equipment?

1. The device has relevant safety operation warnings. Please pay attention to and carefully read these tips when using or maintaining.

2. The use or maintenance of the operator must be professionally trained and operated in strict accordance with the relevant operating procedures.

3. The power supply line of the power supply part needs to have a special protective cover, and the wiring part must have a special terminal block to prevent electric leakage and cause accidents.

4. The protective parts of the equipment are an important part of the equipment and should not be removed at will. If damage occurs, it should be repaired or replaced in time.

5. The lower part of the egg trough is placed at the bottom of the trough. A set of electric shock lines is provided to prevent the chicken from going to the quail egg. Please do not touch it with your hands to avoid being injured.

6. Installation, maintenance or maintenance of electrical equipment related to this equipment shall be carried out by professional electric operators in accordance with the regulations, otherwise serious injury accidents may occur.

7. During inspection, repair and maintenance, the staff must ensure that the main power switch is disconnected and the main power switch is blocked, otherwise serious injury may result.

8. During the operation of the equipment, it is strictly forbidden to observe the operation and operation status of the equipment and open the relevant inspection port for maintenance. If it is really necessary to observe the operation of the relevant components during operation, professional personnel are required to follow the procedures and have the necessary personal protective measures.

9. There are two travel switches installed on the nose and the tail of the machine. When the track wheel of the skip hits any of the travel switches, it will stop running. Regularly check whether the travel switch is sensitive. If it fails, it should be replaced in time. Otherwise, it is easy to pull the truck and the laying hens. The precautions of the laying broiler equipment even lead to more serious consequences.

About chicken immunity decline

%AM, %06 %434 %2019 %09:%MarChickens also have their own immunity, but once the immunity is reduced, they will infect various diseases and cause chickens to fall ill. In order to avoid chicken disease, how to prevent chicken immunity is reduced.

First, the immunity of chickens of different ages and different stages is different. Some chickens themselves have high immunity, and some chickens themselves have low immunity. We have to choose some when buying chickens. Formal,

healthy chicks.

Second, the air quality of the chicken house is also very important for the chicken. The feces in the poultry equipment for sale will produce harmful gases of ammonia, especially in the winter, when the ventilation is poor, the ammonia exceeds the standard directly stimulates the respiratory mucosa of the chicken, and reduces the chicken The immunity is easy to infect respiratory diseases. So in the winter, do the insulation of the chicken house, as well as ventilation, clean up the stool in time, and improve the feed.the utilization rate, maintaining the air quality of the house, is very important for the immunity of the chicken.

Third, the feed mildew will not only affect the chicken eating, causing the chicken to become sick, the immunity is reduced, and waste will be generated, which will affect the economic benefits of the farmers and increase the cost.

How to prevent epidemics when raising chickens?

%AM, %05 %366 %2019 %07:%MarIn the process of chicken farming equipment to raise chickens, the epidemic prevention work is a work that cannot be ignored. The good flocks made by epidemic prevention can reduce or avoid the occurrence of infectious diseases. Then how to prevent chickens from immunization, immunization is the main point of epidemic prevention and The key, the immune effect is the key to the success of raising chickens. To achieve good results in immunization, author reminds farmers to do the following things and points.

1. Daily disinfection: reasonable disinfection can kill the pathogenic microorganisms in the house and reduce the spread of bacteria. In addition, the health of the house has an important impact on the immune effect. Only chickens and chicken houses are in the house. Under hygienic conditions, the vaccination vaccine can produce a strong immune response when the defense mechanism is actively active.

2. Methods and procedures for developing immunization: Different immunization methods are different for different diseases, so farmers should develop a reasonable scientific immunization plan and immunization level according to the prevalence of flock parental diseases and local diseases. In order to effectively ensure the occurrence of flock diseases.

3. Choose a high-quality vaccine: How the quality of the vaccine can directly determine the immune effect, so the farmer chooses the vaccine suitable for the chicken farm according to the advantages and disadvantages of the vaccine. When using the vaccine, it must be strictly in accordance with the instructions. Any vaccine that has no manufacturer, approval number or expired and improperly preserved must not be used.

4. Drinking water should be paid attention to: drinking water immunization is a simple and effective immunization method chosen by many farmers. When using the drinking water method to carry out chicken immunization work, farmers should ensure that the water does not contain chlorine, disinfectants, detergents, etc. The substance that kills the vaccine. Each chicken was given an appropriate immunization dose. At intervals between immunizations, immune monitoring should be performed on the immunized flocks to see if the vaccine is immune.

5. Diseased chickens should not be immunized: farmers should pay attention to the fact that only healthy chickens can produce strong immunity after immunization with vaccines, and weak chickens can affect the production of immunity, in addition to chicken pox and other chronic infectious diseases. Chicken flocks are generally not immune to vaccines.

6. Do a good job of epidemic prevention records: the epidemic prevention work can not avoid the whole cycle only once, and it needs to be carried out regularly. Therefore, in the process of raising chickens, all the farmers must do their work in a diligent manner, and the good memory is not as bad as the pen, so After the vaccine is immunized, the chicken farm shall record the name of the vaccine, the manufacturer, the production batch number, the immunization method, the date of inoculation, the dilution concentration, and the immune effect.

The common problems in raising chicken

%AM, %27 %344 %2019 %07:%Feb1, the feed nutrition is single, do not pay attention to the quality of the feed, or the feed stock is too much, long-term use, vitamins and some nutrients loss, the feed moldy deterioration.

2, the chicken farm should pay special attention to the distance from other chicken farms. If the distance between the houses is too small, there will be serious environmental pollution. It is easy to cause the spread of the disease.

3, neglect the disinfection work chicken farm does not have a sound disinfection management system and procedures; do not pay attention to the disinfection of the chicken house environment; use low-cost disinfection drugs, or reuse a

disinfectant; do not pay attention to the cleaning of utensils, utensils and syringes disinfection.

4, neglecting the daily management, we must observe the growth status of the chicken, use the breeding equipment to raise chickens, and arrange the work reasonably.

5, the chicken poultry farming equipment has poor environmental conditions, the air in the house is dirty, the flow is not smooth, and a large amount of harmful gases such as carbon dioxide and ammonia are generated; the sewage inside and outside the chicken house overflows, the manure is not cleaned in time, the temperature is high and low, and the humidity is too large. Or too small; the outside noise is relatively large, resulting in poor chicken environment, causing a variety of diseases.

Chicken raising equipment introduction

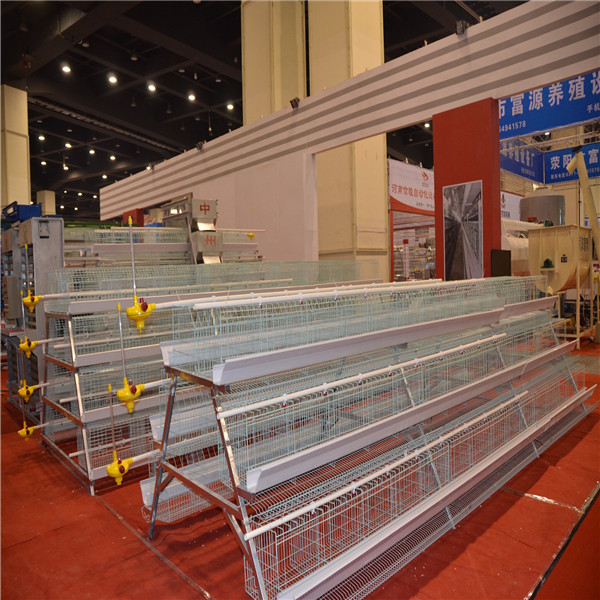

%AM, %26 %387 %2019 %08:%Feb1. Chicken cage is the main equipment for cage chicken houses.

(1) Chicken battery cages: cage brooding, generally adopting 3 to 4 layers of overlapping cages. The total height of the cage is about 1.7 meters, the height of the cage is 10-15 cm, the cage length of each single cage is 70-100 cm, the cage height is 30-40 cm, and the cage depth is 40-50 cm. The mesh is generally rectangular or square, the bottom mesh aperture is 1.25 cm x 1.25 cm, and the aperture of the side net and the top net is 2.5 x 2.5 cm. The cage door is located at the front, and the gap between the cage doors can be adjusted to 2 to 3 cm. Each cage can accommodate about 30 chicks.

(2) Breeding chicken cages: The combined form uses three layers of overlapping type, with an overall width of 1.6 to 1.7 meters and a height of 1.7 to 1.8 meters. The single cage is 80 cm long, 40 cm high and 42 cm deep. The bottom mesh of the cage is 4 cm x 2 cm, and the remaining meshes are 2.5 cm x 2.5 cm. The size of the cage door is 14 cm × 15 cm, and each single cage can accommodate 7 to 15 chickens.

(3) Egg cage: The common forms are stepped, semi-stepped and overlapping. Each single cage is 40 cm long, 45 cm deep, 45 cm high at the front, 38 cm high at the back, and 6° at the bottom of the cage. ~8°. The egg collecting trough extending out of the cage is 12 to 16 cm. The front of the cage door is open, 21 to 24 cm wide; 40 cm high; the lower edge leaves a gap of 4.5 cm from the bottom net. The cage bottom mesh has a hole spacing of 2.2 cm and a weft pitch of 6 cm. The pore size range of the top, side and back nets varies greatly. Generally, the mesh spacing is 10-20 cm, the weft spacing is 2.5-3 cm, and each single cage can raise 3~4 chickens.

2. The poultry feeding equipment includes a feeding machine and a trough. The feeding system of the large chicken farm is mechanized, and the feeding machinery is equipped with a trough.

(1) Chain feeder: It is the most commonly used feeder in China's feeding machinery. It can be used in both flat and cage. It consists of a bin, a link, a drive, a corner wheel, a long trough, and some, and some are equipped with a feed cleaner.

(2) Plug-type feeder: It is designed for dry chicken houses and is suitable for conveying dry powder full-price feed. The 9WS--35 plug-in feeder consists of transmission parts, material boxes, troughs, conveying parts, corners, brackets and other components.

(3) Trough: Commonly used long troughs and bucket-shaped round troughs.

3. Drinking water equipment

(1) Trough type drinking fountain: the depth is 50-60 mm, and the upper mouth is 50 mm wide. There are "V" shaped and "U" shaped sinks. The sinks in the flat chicken house are generally 3 to 5 meters long, and the length of the sink occupied by each chicken is generally 1 to 1.6 cm in the middle chick and 3.6 cm in the breeding chicken.

(2) Tower-shaped vacuum drinker; consisting of two parts: a drum and a water tray, which can be made of galvanized iron and plastic. This type of drinker is suitable for flat chicks.

(3) Nipple type drinking fountain: made of steel or stainless steel, consisting of threaded steel (copper) tube and thimble switch valve, can be directly installed on the water pipe, using gravity and capillary action to control water droplets, making the thimble end often Hang a drop of water. When the chicken needs water, the thimble is touched, and the water flows out; after drinking, the thimble valve seals the waterway and no longer flows out. There are two types of nipple drinkers: chicken and chicken. Each drinker can be used for 10 to 20 chicks or 3 to 5 chickens. The nipple drinker can be used for both flat and cage.

Five matters of standardized management of chicken farms

%AM, %22 %352 %2019 %07:%Feb1. Equipped with breeding facilities

If possible, choose a reputable poultry equipment manufacturers, advanced automatic drinking water system and automatic feeding system should be used as far as possible. Egg farms should be equipped with lighting equipment, large poultry farms should be equipped with storage tanks or warehouses, and fans, wet curtain cooling mechanical ventilation system and other advanced production facilities should be used to give full play to the production level of poultry.At the same time, complete epidemic prevention facilities, including walls, green, ditch and river quarantine zone.Equipped with prevention of rodent, bird pest facilities, equipped with a special veterinary room.

2. Strengthen personnel management

Strictly control the off-site personnel to enter the scale poultry farm. If necessary, they should change clothes and change shoes before entering the disinfection room. It is strictly forbidden to borrow tools between farms. In the eye-catching place of the poultry farm, a warning sign of “free people, no visits” is allowed. All items must be strictly disinfected. Larger farms must be equipped with animal husbandry and veterinary professional technicians who are suitable for the size of the breeding. On a medium-sized scale, there should be more than one technician trained in animal husbandry and veterinary professional knowledge. The breeder is relatively fixed, and there is no postage. The breeder usually observes the health status of the poultry and maintains the environmental sanitation inside and outside the poultry house. Regularly clean and disinfect the surrounding environment, inside and outside the poultry house, utensils, equipment, etc., and at the same time do a good job in rodent control, mosquito killing, and prevention of wild animals and wild birds.

3. Sound rules and regulations

Formulate job management systems for field directors, technicians, and breeders; formulate input systems for inputs such as feed and veterinary drugs; and develop management systems for sanitation, epidemic prevention, and disinfection. In the usual management, we will follow the rules and strengthen the assessment. All systems are on the wall and implemented in accordance with the system.

4. Focus on file management

Establish and improve various account information, production record files including daily production eggs, daily death, daily feed consumption and temperature and humidity and other environmental conditions; input use records including feed, veterinary drugs, veterinary additives and other inputs into and out Library records, feed processing records, veterinary drug group anti-group treatment records; anti-epidemic files including disinfection, immunization, antibody monitoring records; sick and dead poultry processing files including necropsy, harmless processing records; training files including employee training plans and training records. All accounts must be recorded in a timely manner and recorded. The account information is kept for more than 2 years.

5. Implement scientific epidemic prevention

The chicken farm epidemic prevention facilities are perfect, the epidemic prevention system is sound, the immunization monitoring and other epidemic prevention work are carried out in accordance with national regulations, and the comprehensive prevention and control measures for poultry diseases are scientifically implemented, and the diseased dead poultry is treated harmlessly. The farm is equipped with a harmless treatment facility for sick and dead poultry such as a crematorium or a corpse pond, or it can be incinerated by incineration or deep burial. The poultry immunization program was developed based on the actual situation of the field and the results of antibody monitoring, and the immunization program was implemented as planned.

Five matters of standardized management of chicken farms

%AM, %22 %352 %2019 %07:%Feb1. Equipped with breeding facilities

If possible, choose a reputable poultry equipment manufacturers, advanced automatic drinking water system and automatic feeding system should be used as far as possible. Egg farms should be equipped with lighting equipment, large poultry farms should be equipped with storage tanks or warehouses, and fans, wet curtain cooling mechanical ventilation system and other advanced production facilities should be used to give full play to the production level of poultry.At the same time, complete epidemic prevention facilities, including walls, green, ditch and river quarantine zone.Equipped with prevention of rodent, bird pest facilities, equipped with a special veterinary room.

2. Strengthen personnel management

Strictly control the off-site personnel to enter the scale poultry farm. If necessary, they should change clothes and change shoes before entering the disinfection room. It is strictly forbidden to borrow tools between farms. In the eye-catching place of the poultry farm, a warning sign of “free people, no visits” is allowed. All items must be strictly disinfected. Larger farms must be equipped with animal husbandry and veterinary professional technicians who are suitable for the size of the breeding. On a medium-sized scale, there should be more than one technician trained in animal husbandry and veterinary professional knowledge. The breeder is relatively fixed, and there is no postage. The breeder usually observes the health status of the poultry and maintains the environmental sanitation inside and outside the poultry house. Regularly clean and disinfect the surrounding environment, inside and outside the poultry house, utensils, equipment, etc., and at the same time do a good job in rodent control, mosquito killing, and prevention of wild animals and wild birds.

3. Sound rules and regulations

Formulate job management systems for field directors, technicians, and breeders; formulate input systems for inputs such as feed and veterinary drugs; and develop management systems for sanitation, epidemic prevention, and disinfection. In the usual management, we will follow the rules and strengthen the assessment. All systems are on the wall and implemented in accordance with the system.

4. Focus on file management

Establish and improve various account information, production record files including daily production eggs, daily death, daily feed consumption and temperature and humidity and other environmental conditions; input use records including feed, veterinary drugs, veterinary additives and other inputs into and out Library records, feed processing records, veterinary drug group anti-group treatment records; anti-epidemic files including disinfection, immunization, antibody monitoring records; sick and dead poultry processing files including necropsy, harmless processing records; training files including employee training plans and training records. All accounts must be recorded in a timely manner and recorded. The account information is kept for more than 2 years.

5. Implement scientific epidemic prevention

The chicken farm epidemic prevention facilities are perfect, the epidemic prevention system is sound, the immunization monitoring and other epidemic prevention work are carried out in accordance with national regulations, and the comprehensive prevention and control measures for poultry diseases are scientifically implemented, and the diseased dead poultry is treated harmlessly. The farm is equipped with a harmless treatment facility for sick and dead poultry such as a crematorium or a corpse pond, or it can be incinerated by incineration or deep burial. The poultry immunization program was developed based on the actual situation of the field and the results of antibody monitoring, and the immunization program was implemented as planned.

More...

Stepped and battery layer cages, which is better?

%AM, %19 %370 %2019 %07:%FebIn the past two years, there have been fewer and fewer chicken farms with less than 10,000 stocks. There are more and more chicken farms in large scale. We will sort out the equipment for the large and medium chicken farms. I hope to help you.

There are two types of chicken battery cages commonly used, one is a stepped egg cage:

The advantages of the stepped egg cage: the upper and lower layers of the cage are completely staggered, usually 3 to 4 layers.

The utility model has the advantages that the bottom of the cage does not need to have a dung board, and if it is a pit, there is no clearing system; the structure is simple; the ventilation and the surface of each layer are large.

Features:

1. The mesh is smooth to prevent the chicken from being injured in the foot.

2. Separation of the net and the bottom net can effectively prevent the fatigue syndrome of the anus and laying hens.

3. The mesh is galvanized to improve the service life. (Zinc plating is currently divided into cold-galvanized, hot-dip galvanized, hot-swallowed zinc)

4. High-density breeding saves land, is conducive to epidemic prevention, and reduces the incidence of poultry diseases.

5. Unique door reinforcement design, effectively preventing the head from swaying and wasting feed when the chicken is eating. The cage door is enlarged to facilitate various operations on the chicken.

6. Scalability: It can be adjusted according to the size of the site, and an automatic drinking water system can be installed.

7. The chicken manure conveyor belt is installed at the bottom to effectively solve the pollution in the chicken house, and directly transfer the manure to the outside to reduce the manual input.

The other is a three-dimensional layer battery cages:

The three-dimensional egg cage is also called the overlapping egg cage and the stacked egg cage.

1. The three-dimensional egg cage net mesh combination type and hot-dip galvanizing are durable;

2. The bracket is made of cold-rolled roll-formed galvanized. The trough is made of white plastic steel, including adjusting plate, including joint, and plastic mat mesh aperture Q15mm.

3. The egg cage cage wire has a smooth surface, no cracks and scratches and other harmful defects. After the chicken cage mesh is formed, it can effectively prevent the chicken foot injury and prevent the chicken foot from being infected due to the wire laceration. The occurrence of staphylococci;

4. Easy to assemble, easy to raise, easy to manage, save space, effectively prevent infectious diseases, improve the survival rate of chickens;

5. Reduce labor costs, achieve full automation of feeding, feeding, drinking, decontamination and environmental protection, reduce the labor intensity of workers and save labor costs;

6. Investing in the province, using the cascading breeding equipment under the same breeding scale, the breeding density is high, the land is saved, and the degree of intensification is high.

How to adjust the humidity of chicken house

%AM, %18 %397 %2019 %08:%FebIn order to create a good living environment for the chickens, it is necessary to maintain the proper temperature in the house and keep the humidity in the house within a suitable range. Only when the temperature and humidity are in a proper state can the chicken grow better. Here are some ways to adjust the humidity in the house.

First, how to reduce the humidity, we must first increase the amount of ventilation, try not to leak water in the chicken house, to ensure that the water line pipe joints, nipple drinkers, drinking water systems, etc. do not leak, maintain a proper position and height, so as not to leak water after the chicken touches or Sprinkle some water.

Second, when cleaning the chicken house, avoid using a lot of water to wash the chicken house, prevent the water from evaporating and absorb heat, and at the same time reduce the disinfection of the chicken, avoid excessive water sprinkling on the chicken or increase the chicken on the ground. The humidity of the house.

Third, increase the temperature inside the chicken house, the temperature rise will naturally reduce the humidity in the chicken Poultry Equipment for Sale .

Fourth, increase the humidity method, splash water on the radiator or add a spray device in the chicken house to humidify at any time to ensure the temperature is appropriate.