Selection of drinking fountains when using chicken cages

%AM, %16 %119 %2019 %01:%OctDrinking fountains are one of the necessary poultry farming equipment in the process of raising chickens. There are many types of drinking fountains. The best choice of drinking fountains for laying chickens is the “nipple drinker”. The above is adjusted according to the different growth stages of the laying hens, and the water is automatically discharged, which is simple and convenient, so that the laying hen can drink water at any time. The following authors refer to the recommendations of the poultry equipment supplier to tell us how to choose the nipple drinker and the installation points.

1. The performance of the nipple drinker is different, so the farmer should choose according to the breed and age of the flock. The valve opening force is about 40 grams, which is suitable for adult chickens. The valve opening force is about 10 grams. It can be used for chickens and chickens.

2. Although the equipment is basically the same, but the choice of the manufacturer is also very important, the farmers should be regular and have tracking services and after-sales service manufacturers' products, and problems will be solved in the future.

3. When selecting, the farmer should check the quality of the product. The nipple drinker will have a gasket during the production process, but don't underestimate the seal. The inherent quality of the drinker seal is a very important part. The manufacturer uses natural rubber. The pad has a life expectancy of only about half a year. It will become soft and stick to the sealing port in the high temperature environment in summer, resulting in insufficient or no water supply. When the winter is too cold, it becomes hard, easy to aging, and often leaks. This kind of product will bring a lot of trouble to the user. The method of checking the quality of the gasket is very simple. Use a match or a lighter to burn it. If the surface becomes sticky, it cannot be used. Kind of material can not be purchased.

There are two ways for general farmers to install a nipple drinker. One is installed above the layer chicken cages, which is above the middle, and the other is installed on the front of the egg cage. Both have their own advantages and disadvantages, and farmers can consider how to install them. Installed in front of the egg cage, the water droplets drip in the trough can ensure that the chicken manure is dry and easy to maintain, but the feed under the drinker is easily wetted. Installed in the middle of the egg cage, although it will not affect the feed, it will also affect the chicken manure, so the farmers can decide. In addition, the installation of the nipple type drinking fountain must be standardized, otherwise it will easily cause problems such as uneven water supply.

Farmers must pay attention to the water supply immediately after the installation of the nipple drinker. Because the drinker is just installed, the chicken will only feel fresh and use it to remove the sputum. As soon as the water is discharged, it will form a conditioned reflex. If you are thirsty, go and squat. If you don't give water in time after you install it, the chicken won't leave anything, so you won't be embarrassed. You don't know if you want to drink it. However, it should be noted that the drinker cannot be used within 20 days after the chicken is broken, because it is so painful that it does not dare to lick.

The above is about the choice of drinking fountains when using chicken battery cages to raise chickens. In addition, many farmers will choose to add immune drugs to drinking water to immunize drinking water, but in the process of immunization, we must pay attention to the choice of drugs and other issues to avoid immune failure.

Mistakes in using chicken cages to raise chickens

%AM, %11 %410 %2019 %08:%OctNowadays, the chicken industry is popular in the use of new layer chicken cages. Many farmers have increased their benefits, and farmers have begun to transform and start to raise. However, some farmers have not improved their efficiency. Many users think that it is a problem of their own equipment. Actually, most of them are caused by some details not being done properly during the usual breeding process.

First, attach importance to disease treatment, neglect disease prevention: Many farmers do not have the concept of preventing diseases, and believe that prevention is the same as getting sick, treatment is enough, but in the process of treatment, drugs have an impact on the quality of the flock and production performance. Even if the diseased chicken is cured, it will not be the same as in the healthy period. "Prevention first, anti-heavier treatment" is the principle that must be observed in the scale farming process. Some conditions are simply uncontrollable, usually only done. Good prevention work can get better control.

Second, the management system is not clear: Many farmers use the chicken battery cages to raise chickens. It is the same as the previous flat-fed chickens. Regardless of the chickens, they think that they can eat and drink well, and they don’t pay attention to observing the chickens. Record the health status of the flock at any time, such as: feed intake, death rate, medication, etc. are not clearly recorded. There is no digital concept at all when farming, and such aquaculture success rate is small.

Third, farmers do not pay attention to the health of the chicks: when selecting chicks, many farmers are picking cheap choices, regardless of the health of the nursery and the quality of the chicks. Good chicks are the premise for farmers to raise chickens. Therefore, when the price of chickens is high, don't blindly save money. Don't choose cheap chickens to bring unnecessary losses to our farming.

4. Pay attention to the survival rate and neglect the compliance rate: Some farmers think that as long as the chickens grow healthily, the survival rate will be high, and they will not pay attention to the uniformity of the chickens and whether the weight is up to standard. Many users feel that they are alive. The rate can be ah, the feed also eats a lot, why the chickens have no benefit, do not blindly pursue the survival rate when breeding, but ignore the ratio of meat to meat, the proportion of meat in our farming process accounts for a large proportion.

5. Feed nutrition is endless: the nutrients required for different growth stages of the flock are different. Many farmers do not understand this. The feed ingredients have not changed, resulting in uneven nutrition of the flock. In different seasons and different ages, the demand for nutrition in feed is different. To reduce the cost of feeding, it is necessary to adjust the feed nutrition in time according to the nutritional needs of poultry.

Sixth, sanitation, disinfection does not separate home: before disinfection, many farmers have no habit of cleaning the chicken coop, that only disinfection can be. However, if you do not clean the house, disinfection will only disinfect the surface of the dirt, so disinfection is no different from disinfection.

The above is the author's experience in poultry equipment suppliers, telling a few chicken misunderstandings. In short, the above situation has occurred in many farms. In order to obtain greater economic benefits, it is hoped that farmers will be able to strengthen their feeding management in light of the actual situation of their own chicken farms.

Measures to increase laying rate of laying hens

%AM, %27 %411 %2019 %08:%SepThere are many factors that influence the laying rate of laying hens. When the breeder chooses the breeder's breed, whether the chick is good or not, whether it is scientifically raised during the feeding process, the environment of the chicken house and the disease of the laying hen can affect the laying of the laying hen. Now the author will talk about measures to increase the laying rate of laying hens when using battery layer chicken cages to raise chickens.

1. Variety quality: The material basis of the seedling-bearing varieties, the quality of the varieties is reflected by the quality of the seedlings. The quality of the seedlings is usually evaluated by the purity of the quality and the purity of the health. The quality of the pure refers to the pure non-hybridization of the breed. Health and purity means strong and no harmful bacteria and viruses. In practice, only the price is not focused on quality, and only the weight is not focused on blood tests. The key to choosing a good variety: First, choose a big brand, second, do a good job in the preliminary investigation and investigation, and third, conduct quantitative testing and testing.

2. Environment: The feeding mode determines the production environment of the chicken. However, it is now popular in the aquaculture industry to use a full range of poultry farming equipment to raise chickens, which has little effect on the performance of laying hens.

3. Feeding: Feeding management affects all aspects of chicken production performance. Feeding management level is the key to raising chicken. It takes time and practice to accumulate. Weight, feeding and chicken are the basic requirements for feeding management.

The uniformity of weight of chickens seriously affects the laying performance of chickens. The breeding process of young chickens should be guided by uniformity. The egg laying process should also pay attention to group uniformity.

Feed nutrient level should meet the feeding standard, and feeding evenly is more important. Feeding evenly during the feeding period can ensure uniform body weight. Even feeding during the laying period can ensure the egg production rate is stable. Feeding evenly can maximize the effect of the feed and ensure feeding. Uniform feeding is the only way to reduce the hidden waste of feed.

Let the number of chickens in each egg cage be the same, ensure that the weight development of young chickens is consistent, ensure that the feeding amount of laying hens is the same, adjust the flocks by each immunization, and select the sick and weak chickens by inspection.

4. Disease prevention and control: prevention of the disease is the premise to ensure the performance of laying hens, and bacterial diseases, metabolic diseases, etc. can not be ignored. The measures for the prevention and control of epidemic diseases are to establish a system, comprehensive prevention and control, use both dead and live seedlings, and repeat immunization, select poisonous type, cross protection, key seasons, and closed breeding.

The performance of laying hens is affected by variety, environment, disease and feeding management. Pure quality, suitable environment, anti-epidemic disease and weight, feeding and even distribution of chickens, will certainly achieve excellent production results.

The above is the author's recommendation with the poultry farming equipment suppliers. From four aspects, the measures to improve the egg production rate are expected to help the farmers. Thank you for your attention!

Broiler cage raising house management technology

%AM, %20 %374 %2019 %07:%SepThe use of broiler battery cage equipment for broiler chickens is now an indispensable device for broiler chickens. At present, there are more and more manufacturers producing broiler cage equipment, and the types are increasing. The choice of farmers has also increased. But no matter what manufacturer's broiler cage is chosen, scientific feeding management is the focus. Then, how to carry out feeding management by raising chickens in broiler cages?

1. Temperature: There is a temperature difference when using a chicken cage. The lower the temperature outside, the greater the temperature difference in the room. Feeding brooding is generally at the highest level because the highest temperature is the highest, which is conducive to saving heat. On the first day of the chicken entering the cage, the temperature is controlled at 33-34 °C, and the temperature can be adjusted according to the condition of the chick. When the temperature is suitable, the flocks are evenly distributed, lively and active, and have a strong appetite; when the temperature is low, concentrate on the heat source. Squeeze each other, the body trembles; when the temperature is too high, the amount of water increases, the appetite decreases, the breathing speeds up, and the neck feathers are soaked. In the first week, the temperature dropped to 30~C, and then decreased by 2°C every week. The density of cage culture was large, which was 1~2~C lower than the flattening temperature. The heat stress should be avoided and the food intake should be reduced.

2. Ventilation: The key to the use of broiler cage farming is ventilation. Only reasonable ventilation can discharge harmful gases, control temperature and reduce the occurrence of diseases. The density of the unit area of broiler cage farming is large, so ventilation is more important. Within 24 hours after the chickens enter the scene, due to the large space of the whole chicken, it is not necessary to ventilate. As the age of the chicken increases, the ventilation volume is gradually increased, and the position and size of the air inlet are adjusted. The time and season should be adjusted continuously, and the air in the house should be odorless, glare-free, oxygen-free, and comfortable. To create a good growth space for chickens, it can enhance the body's disease resistance and reduce the incidence of diseases.

3. Use of poultry farming equipment: Nowadays, relatively large chicken farms have relatively advanced and perfect poultry farming equipment. But if you have equipment, you don't necessarily have to raise chickens. With the increasing scale and automation, farmers should be familiar with the principle of equipment and skilled operation, and always observe. For example, the temperature controller, the temperature controller and the temperature of the house have a certain error, this error value should be adjusted to the minimum, so that the temperature of the house can be adjusted to the optimum temperature for the chicken. In addition, the operator must be proficient in the use of the equipment, and the feeding procedures of the chicken at various stages, and can promptly discover and repair equipment failures. Once the equipment is used improperly or the equipment fails, it will cause huge economic losses.

4. Drinking water: After entering the chicken battery cages, the chicken should ensure that the water can be drunk within 2 hours. The purpose is to let the chicken learn to drink water as soon as possible. In addition, the height of the automatic drinker should be adjusted in time, and the height should be moderate. Too low or too high will affect the drinking water of the chicken. In addition, it is necessary to properly adjust the pressure reducing valve on the drinking line. The pressure is too high, the chicks are afraid to avoid and waste water resources; the pressure is too small, and the drinking water at the end of the chick may not reach the standard. As the age of the chicken increases, the water pressure is appropriately increased. The first time the chicks drink water, they should use warm water at 25 °C and add 5% glucose and 0.1% vitamin C to the water. The drinking fountain should be washed frequently. During the whole brooding period, the drinking water can not be interrupted. From the second day of brooding, the medicine for preventing chicken white pheasant is added to the drinking water.

5. Illumination: Most of the chicken houses in broiler cages are artificially illuminated, because artificial lighting makes it easy to control the lighting time. Seven days before brooding, 24 hours of light is generally used, and then gradually 22 hours. The purpose is to let the chicks get used to the dark environment, so that the chickens will panic due to a sudden power outage, and crush casualties will occur. Then gradually increase to 24 hours of light a week before the release.

Disinfection precautions for broiler cages

%AM, %18 %426 %2019 %09:%SepThe cold winter is about to pass, and the spring is coming, and the spring is the stage where poultry is highly susceptible to various diseases. Therefore, before the arrival of spring, farmers must understand some diseases that are prone to spring chicken flocks in order to be aware of prevention. The source of the virus is mainly the environmental impact in the house. Therefore, in the spring, disinfecting the chicken house is the best preventive measure to prevent diseases caused by chickens. Disinfection and fumigation in spring broiler houses are an effective method. Fumigation is the use of formalin to react with potassium permanganate to produce formaldehyde gas, which kills pathogenic microorganisms after a certain period of time. The biggest advantage is that the fumigant can be evenly distributed to all corners of the poultry house, and the disinfection is comprehensive and thorough, especially suitable for the disinfection of polluted air in the poultry house. However, when using fumigation sterilized chicken battery cages, you should also pay attention to some matters. Here are some tips for the farmers to pay attention to.

1. The chicken house should be sealed when it is disinfected. Only in this way can it be completely disinfected. If there is a gap, it can be sealed with tape or plastic cloth.

2. It is easy to have corrosion resistance. Because both potassium permanganate and formalin are corrosive, the reaction after mixing is severe, generally lasting 10-30 minutes. Therefore, the container of the drug should be large enough and resistant to corrosion.

3. Before the fumigation and disinfection, the manure in the house should be mechanically treated and sprayed. Because formaldehyde produced by the reaction of formalin and potassium permanganate can only disinfect the surface of the object.

4. When fumigation is carried out, the temperature in the house should not be lower than 18 degrees Celsius, and the humidity should be kept at 60%-80%. Only in this way can the disinfection effect be best.

5. The proportion of mixed syrup should be appropriate. Generally, 30 ml per cubic meter of formalin, 15 g per cubic meter of potassium permanganate and 15 ml of water per cubic meter are suitable.

The above is the disinfection that the author should summarize for you when you sterilize the broiler battery cages. Disinfection in the house is essential, and each farmer should strengthen this aspect of attention in order to avoid subsequent economic losses.

Composition of the layer chicken cage equipment system

%AM, %16 %392 %2019 %08:%SepNigeria's mechanized chicken industry has begun to mature and mature, and poultry farming equipment and related environmental control technologies have made progress. For example, nipple drinking equipment, automatic feeding equipment, wet curtain evaporation and cooling equipment, fans and vertical ventilation equipment.

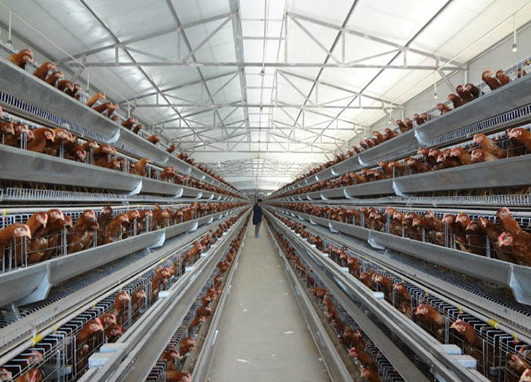

The layer chicken rearing equipment is mainly composed of a cage system, a feeding system, a drinking water system, a lighting system, a waste disposal system, an automatic egg collecting system, and an environmental control system. The use of mechanized laying hen cage equipment allows for a rhythmic cycle of hatching, brooding, and the production of the last commercial chicken or commercial egg. Most of the houses are closed or semi-enclosed, with automatic adjustment equipment to control the microclimate and lighting in the house, so that the house can be produced in a balanced manner throughout the year, achieving high mechanization and automation. In this mechanized farming mode, the breeder can automatically complete the feeding, collecting eggs and removing feces of the chickens. And automatic ventilation, control of temperature and humidity in the house, light intensity time, spray disinfectant and add soluble drugs to drinking water.

In addition to manually picking up dead chickens, breeding insemination, daily quarantine and injection vaccination, all processes can be automated using the machine. In the broiler rearing equipment in the past two years, there have even appeared equipment and conveying equipment that can batch out the whole chicken house, which is a big breakthrough in the field of broiler feeding technology with short feeding period.

At present, the poultry breeding equipment in Nigeria is mainly imported. When farmers purchase poultry farming equipment, they must pay attention to the selection of high quality poultry equipment manufacturers.

Precautions for using poultry farming equipment accessories

%AM, %11 %420 %2019 %09:%SepPoultry farming equipment - the production and use of automatic feeders, large and medium-sized farmers have greatly solved the problems of feeding chickens, long time and labor intensity. Especially for farmers who use chicken rearing equipment in Nigeria for farming, it is more convenient. The feeder can feed three to five layers of chickens, which effectively improves the work efficiency and is a good helper for farmers. The following authors will pay attention to what matters should be paid attention to during the use of the automatic feeder for the reference of the farmers.

What are the precautions for using the automatic feeder?

1. Pay attention to timely inspection. The inspection is divided into three parts: the top of the feeder, the belt, and the motor. Because the automatic feeder can not place heavy objects on it, it will burn out when the feeder is driven because the pressure of the motor is too high, which greatly affects the life and effect of the feeder. Therefore, before starting the machine, it is necessary to check whether there are heavy objects placed on it, and if so, take it away in time. The belt of the feeder plays a big role in the work process, so it is necessary to check the belt for looseness in time. The main part of the feeder is the motor and the geared motor, so pay special attention to whether the motor has abnormal conditions, and if necessary, deal with it in time.

2. Pay attention to clean up. Because the dust will be generated during the operation of the feeder due to the production of feed, if the dust remains on the machine, it will cause dust in the control box of the feeder, which may eventually lead to short circuit and affect the machine. Therefore, when using, remember to regularly clean the feeder.

3. Maintain lubrication between the parts supplied by the feeder. Because the feeder generally has a lot of gears and chains to connect and work, if there is no lubrication between the gear chains, the components in the feeder will wear out, which will affect the working effect and efficiency.

The daily maintenance work of the automatic feeder mainly includes: 1. Regularly clean the dust on the rack to keep the parts of the feeder clean. Regularly add lubricant to the conveyor chain and other transmission components to make them operate freely, reducing wear and prolonging service life. 2. Regularly check whether the fastening parts of the feeder are loose. If it is loose, fix it in time to ensure the safe operation of the feeder. If the motor, appliance or control switch fails, you should ask a professional to repair it.

The above is the content of the author's consultation with the technical staff of the poultry farming equipment suppliers, please use it flexibly.

Some advantages in the use of farming equipment

%AM, %09 %432 %2019 %09:%SepThe use of automated poultry farming equipment is becoming more and more popular in the aquaculture industry, and its advantages in the breeding process are becoming increasingly clear. The following is no longer a description of the advantages of the farmers in the application. Today, the farmers mainly talk about some of the equipment included in the complete chicken equipment, so that the farmers can do their best when purchasing equipment.

1. Cage: Cage is the most basic equipment in the complete chicken equipment is also an essential equipment. Whether it is raising broilers or laying hens, it is necessary to purchase them. When using cages, it can increase the number of feedings and save the area of the house.

2. Decontamination system: The decontamination system mainly refers to the decontamination machine. The septic machine is divided into a scraper type septic machine and a belt type septic machine. Both types of septic equipment can clean the faeces in the house and reduce air pollution. When the households are purchasing, they can choose the right type of cleaning machine according to their own feeding conditions.

3. Feeding system: Feeding system refers to the feeding machine. The breeder can directly feed the prepared feed with good nutritional value. The feeding machine can also control the feeding amount of the feed well. The uniformity of the diet of the flock.

4. Ventilation and cooling system: The main ventilation and cooling system used in the chicken house is the fan and the wet curtain. The scientific installation method utilizes the effect of negative pressure to lower the temperature inside the house. This will create an outstanding living environment for the flock.

5. Automatic egg collecting system: the egg collecting machine is mainly used in the equipment of laying hens. The egg collecting machine can assist the keepers to collect eggs, increase the number of times, and reduce the breakage rate of eggs, and then improve the economic benefits of the keepers.

The above is an introduction to the various systems in the complete chicken equipment. I hope that after the introduction today, it will provide some help for the farmers to purchase poultry farming equipment in the future.

More...

Feeding density when raising chickens using poultry farming equipment

%AM, %05 %423 %2019 %09:%SepWhat kind of feeding density is reasonable when using layer chicken cages to raise chickens? We all know that chickens have a short feeding cycle and chickens grow faster. In the process of raising chickens, if the breeding density is too large, the growth of the chickens will be hindered and the health of the chickens will also be affected. The appropriate density of chicken feeding is related to the effectiveness of raising chickens. It is necessary to describe the reasonable stocking density of chickens.

1. The effect of excessive density: During the process of raising chickens in chicken cages, the stocking density controlled by the farmers has a great influence on the health and growth of the chickens. The density is too high, the chickens are stepped on, the accidental mortality rate is high, and the epidemic rate is high. High stocking density has a negative impact on the growth performance, dynamic composition and meat quality of the chicken, which can reduce the quality of the chicken. Moreover, the density is too large, the air inside the house is simply polluted, the sanitation environment is not good, the food is crowded, the water is grabbed, the hunger and the food are uneven, and the formation of chickens is slow and the development is not neat. It is easy to infect diseases and sputum, which increases mortality.

2. Reasonable density for raising chickens: For newly born chicks, the farmers can control the stocking density at around 30/m2. Then as the chick grows up, the space is gradually enlarged or dispersed. When the chicken grows to 40 days old, the stocking density is generally 10-15/m2. Of course, if it is a non-closed house, it can raise 10/m2, the closed house can be 12/m2, and the environmentally controlled house can reach 13/m2.

The above is the author's reference to the experience of poultry farming equipment suppliers, the issue of raising the density of chickens in chicken cages for the farmers. Reasonable stocking density is a key factor in the success of chicken rearing, which is also the key knowledge of chicken breeding technology. The breeder must correctly arrange the density of the chickens to raise the chickens scientifically and efficiently to ensure the healthy feeding of the chicken farms.

The main point of using chicken equipment to raise chickens scientifically

%AM, %03 %410 %2019 %08:%SepWith the rapid development of the chicken industry, the chicken industry has gradually become popular with various types of poultry farming equipment for mechanized chicken raising mode, making chicken raising easy and efficient. Many users have joined the pace of raising chickens, but raising chicken is not a simple matter. Mastering the techniques and management methods of raising chickens, and keeping the chickens in accordance with the laws of healthy growth of the chickens can raise the chickens. To reduce the risk of farming, the following authors will introduce the principles to be followed in the scientific use of poultry farming equipment.

1. To be well managed: Most farms are large-scale, intensive farming models. Farmers should pay attention to management in the process of breeding. The core problem of management is coordination. Only management is good. Execution has fewer problems and no problems.

2. To ensure the safety of the flock: Only when the flock is healthy can the normal growth of the flock and good egg production performance be ensured. Therefore, when the farmers are raising and managing, the safety of the chickens should be caught. Strict disinfection, effective isolation, elimination of flies and rodents, all in and out.

3. To do a good job in chicken farm immunization: immunization is an effective means to prevent infectious diseases in the breeding process. It is a work that farmers must pay attention to and must do. Farmers only make reasonable and reasonable according to the actual situation of the chicken farm. Immunization procedures and methods are carried out correctly to avoid immune failure.

4. It is necessary to do the breeding work of brooding: brooding work is a stage that every farmer has to go through. The survival rate of the chicks can determine the health and productivity of the flocks in adulthood, so the farmer has to learn the adult egg broiler. In addition to feeding management techniques, special attention should be paid to the feeding and management techniques of chicks.

5. To do a good job in employee training: Generally, large and medium-sized farms need some employees to complete a series of work in the chicken farm. In order to better enable employees to do their jobs, farmers should pay attention to employees' familiarity with equipment. Work, management, and management to avoid irregularities or even operational errors.

6. It is necessary to do a good job in raising chickens and environmental protection: the environment is a problem that the country attaches great importance to. Especially for the chicken industry, it is said that it is necessary to carry out maintenance of chickens. Environmental protection must be paid attention to, waste water, smoke, feces, and death. Chickens and other items must be handled in strict accordance with relevant state regulations. Violation of the law will cause operational risks in chicken farms.

7. It is necessary to do a good job of standard medicine: standardize medication, scientific use of medicine, use less medicine, eliminate drug residues, and implement food safety. In this way, farmers can be guaranteed a good income in the process of breeding, and the chickens of the farmers will be more popular in the market.

The above are the basic principles for the farmers to use the chicken farming equipment for scientific chicken raising. It is hoped that the farmers must combine several principles to raise chickens in the process of raising chickens, so as to obtain the economic benefits of chicken farms smoothly.