How does a chicken farm regulate the temperature in the chicken cage

%AM, %04 %356 %2020 %07:%AugFarmers who raise chickens know that the environment of the chicken house is well controlled and temperature control is important for healthy chickens. The environmental control of the chicken house has become an important link in the efficiency of the farm. In the environmental control of the chicken house, the more important part is the temperature control in the chicken house. Then how do we adjust the problem of the chicken house, and use those breeding temperature control equipment to help us quickly adjust the temperature?

One is to check the airtightness of the chicken house.

The airtightness of the chicken house directly affects the work of the breeding temperature control equipment, and affects the fresh air in and out requirements, and the temperature difference is reasonable.Now they are all use modern poultry farming equipment raise chicken We need to pay attention to the places to be checked are the middle door, the manure scraper opening, the junction of the water curtain and the wall, the side wall vents, etc. These places are well checked, and we can have good air in the ventilated airtight .

Second, pay attention to the negative pressure value in the house.

The negative pressure value is also called the static pressure difference, which is the difference between the atmospheric pressure inside and outside the chicken house. In a well-sealed chicken house, when all air inlets are closed, start the exhaust fan, and the static pressure difference in the chicken house, that is, the negative pressure value must exceed 0.12 inches of water column. The certain wind speed of the vent formed by the negative pressure will change due to changes in the outside weather or the temperature difference between day and night. At this time, the controller will automatically adjust the negative pressure, but due to various facilities and human factors, deviations will be caused. Excessive negative pressure in the house will cause uneven wind speed and temperature in the front and rear of the house, resulting in hot and cold stress on the flocks in the house.

Third, it is necessary to adjust the fan water curtain.

In some areas, the temperature difference between day and night is too large or the weather changes in summer. At this time, mixed ventilation combining horizontal ventilation and vertical ventilation should be adopted, so that the temperature of the chicken house will not change too quickly. When the fan in the house is turned on to half of all fans, it is necessary to change from mixed ventilation to longitudinal ventilation. When using longitudinal ventilation, all side wall vents must be closed. When one or two fans in the house can be turned on, lateral ventilation can be used. The opening and closing of the water curtain should also be coordinated with the fan. When the temperature rises, first increase the ventilation and wind speed. At this time, observe the temperature of the chicken house.

Fourth, it is necessary to understand the effective temperature and body temperature.

The air flow above the chicken flock can have a convective cooling effect, and the overall air velocity throughout the chicken house will have an air cooling effect on the chicken flock. Whether the chicken house is well ventilated and the temperature is appropriate, you should not just look at the temperature displayed by the thermometer and thermostat, but the body temperature of the chicken. In other words, it must be based on observing the feeding, drinking, singing, resting, and mental status of the chickens.

Five, it is necessary to clean and maintain in time.

The temperature adjustment equipment should be cleaned in time. If it is not cleaned, the pressure probe will be blocked and affect the work of the temperature adjustment equipment.famous poultry cage suppliers in nigeria is also like this

The chicken cage manufactures will tell you how to raise and manage caged broilers

%AM, %31 %414 %2020 %08:%Jul1. The indoor temperature must be strictly controlled. The room temperature before the human chicks is around 30℃, and the room temperature gradually rises to around 33~35℃ after entering the chicks. It is best broiler cages to brood broilers in the uppermost layer in cages, with 27.30 broilers per cage. Use a small feed pan to fill up the feed in advance and place it in the cage. Add water to the water tank in advance for pre-warming (consistent with the indoor temperature). After the chicks arrive on the site, quickly put the chicks in the room, place them evenly, and then count the cages. 3 to 5 days before brooding.

2. It's best to feed every morning. It is better to feed the automatic feeder 3 times a day. If using a trough, manual feeding must be added evenly. And feed it in time. To prevent chickens from trampling due to hunger, the breeder checks whether there are empty troughs every afternoon and feeds them in time. Technicians should check the feeding situation of the trough every day, and take timely measures if there are too many leftovers. Analyze and judge the possible situation: there are fewer chickens in the cage. Replenishment should be made in time; whether the nipples are lack of water; whether there are sick chickens in the cage, they should be selected for individual treatment or eliminated in time; whether there is insufficient lighting, timely measures should be taken and adjustments should be made.

3. The normal water supply should be guaranteed for 24 hours. Water should be controlled when removing medicine or making seedlings. Check whether the water line is blocked frequently. This is a crucial issue for every chicken farm, and it must be detected and repaired early. The nipple leaks, the water flowing out wastes medicine, and the feces will flow into the trough after diluting the feces into the stool tray. One is waste of feed, and the other is intestinal diseases.

4. The humidity during brooding should generally be around 65-70%. Afterwards, the humidity will gradually decrease to about 60%. Cage broiler chickens are prone to lack of humidity in the room, and it is the best way to use warm water spray to disinfect the chickens. If the humidity is too high. Increase the temperature and increase ventilation.

5. The brooding temperature is generally 33~35℃. According to this benchmark. As the chickens grow older. It drops two degrees a week, not hot and cold. Technicians and breeders should always pay attention to weather changes, keep abreast of the outside temperature, and appropriately adjust the ventilation volume according to the required temperature. Chickens need a suitable temperature for rapid growth. To grow faster, the temperature must be relatively high.

6, Ventilation is an important part of the breeding process. Ventilation will begin in the first week. When opening the skylight, part of the side windows should also be opened appropriately, and the sealing should be at a certain angle upwards. While ensuring the temperature, properly increase the ventilation. As the age increases, the ventilation volume gradually increases. When approaching the age of 20 days, the longitudinal fan needs to be turned on, because the ventilation volume of the side window is too small to meet the needs. According to the required ventilation volume, outside temperature, season, indoor air quality, a speed regulator, fan speed, and time should be installed The length will vary according to the specific situation. Don't have too much air volume, otherwise the chicken will only cause a cold. If the weather changes suddenly and the wind is too strong, the side windows should be closed temporarily.

7. Timely removal of manure is a very important link, and the use of manure trays for chicken farms is even more important. Chicken manure accumulates too much heat from fermentation to fumigate the chickens. Suddenly cleaning the manure, the chicken loses this part of the heat, and the relatively cold stimulation will cause a cold. In addition, it should be noted that when pushing manure outdoors, one of the doors at both ends of the chicken house should be closed. If both doors are open, excessive draughts will cause the chickens to catch cold.Or use poultry manure removal system also is great ideal.

Chicken cage manufacturers talk about the feeding density of chickens

%AM, %29 %419 %2020 %09:%JulWhen using poultry farming cages to raise chickens, what is the reasonable stocking density? We all know that the breeding cycle of chickens is short, which means that the growth rate of chickens is relatively fast. If the breeding density is too high during the process of raising chickens, the growth of chickens will be hindered, and it will also affect the health of chickens. Whether the breeding density is appropriate or not is related to the unevenness of the chicken breeding efficiency of the breeder. The author will describe the reasonable breeding density of the chickens.

1. The impact of excessive density: In the process of raising chickens in chicken cages, the raising density controlled by the farmers has a great impact on the health and growth of the chickens. If the density is too high, the trampling of the flocks will increase, the accidental death rate will be high, and the incidence of disease will be high. High stocking density has a negative impact on chicken growth performance, dynamic body composition and meat quality, and will reduce chicken quality. Moreover, the density is too high, the air in the house is simply polluted, the sanitary environment is not good, food is crowded, water and food are rushed, and the food is uneven. The formation of chickens produces slow growth, irregular growth, susceptibility to diseases and seizures, and increases mortality.

2. Raise chickens at a reasonable and appropriate density. For more born chicks, the breeder can control the stocking density at about 30 birds/m2, and then gradually expand the space or disperse as the chicks grow up. By the time the chickens are 40 days old, the stocking density is generally 10-15 birds/m2. Of course, if it is a non-closed chicken house, it can maintain 10 birds/m2, a closed chicken house can be 12 birds/m2, and an environmentally controlled chicken house can reach 13 birds/m2.

The above is the author's description for the breeders, the problem of stocking density when using poultry farming chicken cages to raise chickens. Reasonable breeding density is the key factor for the success of chicken breeding. This is also the key knowledge of chicken breeding technology. Chicken breeders must correctly arrange the chicken breeding density to raise chickens scientifically and efficiently to ensure the healthy breeding of chickens in the chicken farm.

The chicken cage factory will tell you how to manage the laying hens

%AM, %29 %372 %2020 %07:%JulWith the rapid development of the chicken industry, the market has put forward higher and higher requirements for the output and quality of eggs, so the breeding of layer hens has become the key to egg production. Next, based on actual production, the chicken cage factory will talk about the management of laying hens.

1 Physiological characteristics of laying hens

Although the hens who have just started laying are sexually mature and begin to lay eggs, the body has not yet fully developed, and the body weight continues to increase at the age of 18 weeks. Growth and development basically stop at the age of 40 weeks, with very little weight gain. After 40 weeks of age Most weight gain is fat accumulation. Laying hens of different ages have different utilization of nutrients. When the hens just reach sexual maturity (17-18 weeks of age), the mature ovaries release estrogen, which significantly increases the calcium storage capacity of the hens and starts to lay to the peak of laying. During the period, the chicken's ability to digest and absorb nutrients is enhanced, and the feed intake continues to increase. In the late stage of laying, the digestion and absorption capacity is weakened, and the fat deposition capacity is enhanced. The body weight, egg weight and egg production of laying hens have a certain regular change in the first laying cycle. According to these changes, it can be divided into three periods: pre-laying period, peak period, and laying period Late.

2 Feeding management in the early stage of layer in automatic layer cage system

In the first 3 to 5 days before the transfer, prepare and disinfect the laying hen house, and do the immunization and repair work of the reserve hens before transfer. The light management during the laying period should be consistent with the light during the rearing period. Raised in an open chicken house, if the transfer group is in a season when natural light is gradually increasing, and the chickens fully adopt natural light during the rearing period, the light hours have reached 10h or more when the group is transferred. Artificial lighting is used. When natural light starts to become shorter, artificial lighting is added to supplement it. The progress of artificial lighting subsidy is increased every week.

3 Daily management during the laying period

There must be a certain empty slot time from 12 to 14 o'clock every day to prevent long-term storage of feed in the trough, causing chickens to have anorexia and picky eating habits. Each feeding should be evenly thrown while feeding, so that the fed material is evenly distributed in the trough. About 30 minutes after feeding, the feed should be evened once. This is because the chickens eat quickly in the first 10 minutes after feeding. They are picky eaters and hook feeders. At this time, there is still more feed in the trough. The chickens will quickly hook the feed in the trough into small piles, which makes the feed distribution in the trough extremely uneven, and often hooks the feed outside the trough. The waste of feed affects the feeding of other chickens. Do not add more than one-third of the depth of the trough each time.

4 Management during peak egg production

Keep the environment of the chicken battery cage system as stable as possible and reduce the interference of various stress factors as much as possible. According to the situation of the flock, preventive administration or administering broad-spectrum antibacterial drugs for 3 to 5 days every other month, and timely supplementation of nutrients, can ensure high-quality egg production.

Stepped brood cage manufacturers teach you to choose chicken cage

%AM, %27 %436 %2020 %09:%JulIn addition to good brood management, it is also very important for breeders to choose an environment suitable for brooding growth. Nowadays, breeders will choose to use stepped battery cage for chickens to raise their chicks. So how should breeders choose stepped brooding cages? Here are a few key points.

There are many factors that can affect the growth and development of chicks, such as genetics, nutrition, and environment. In the case of small differences in the overall nutritional level of the farm, the environment of the farm becomes the key to determining the success of the farm. Among the many environmental factors, the temperature, humidity, ventilation and light of the chicken house are the most critical and the most difficult to control in daily management. In order to save breeding space and improve breeding efficiency, large-scale farms usually adopt cage breeding. The level and position of the cage are different, and the surrounding microenvironment (temperature and humidity, light, ventilation) will also be different.

The main points of choosing a stepped brooding cage:

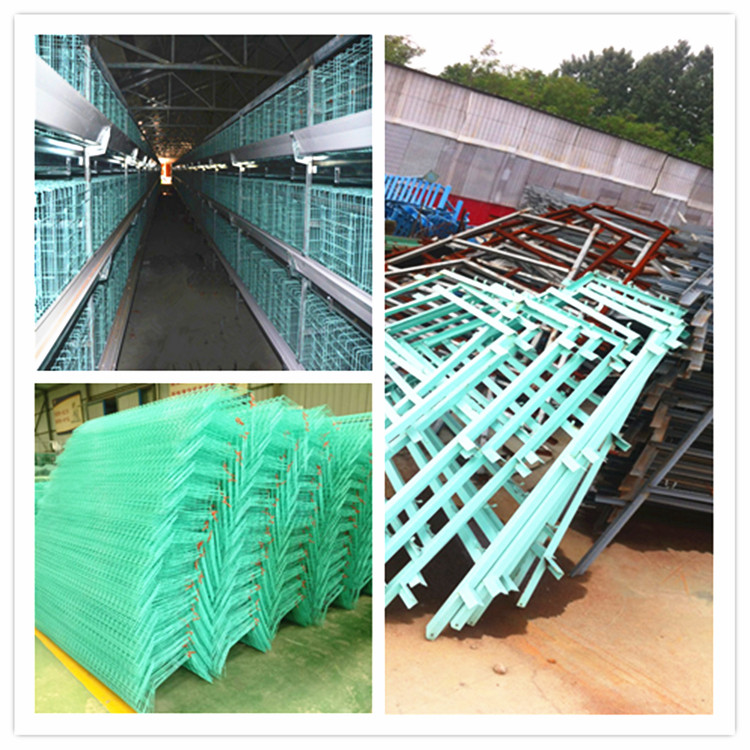

1. Material: Low carbon steel galvanized cold drawn steel wire, fine galvanized, corrosion resistant.

2. High-quality plastic can overcome the inflammation of the broiler breast caused by the hard bottom of the cage.

3. Adequate sunlight, good ventilation, and free drinking water.

4. It saves labor and materials, manages, observes, disinfects, cleans manure, and is easy to operate.

5. Rugged, durable, beautiful, easy to apply and save space.

The above are the key points when choosing brooding cages summarized by the stepped brooding cage manufacturers, for reference by farmers. In addition to choosing good breeding equipment, daily management is also particularly important.

What should I pay attention to when feeding laying hens in autumn?

%AM, %23 %314 %2020 %06:%Jul1. Environmental regulation The growth and development of laying hens are affected by factors such as temperature, humidity, light, harmful gases, fright, noise, environmental sanitation, disinfection, mosquitoes and flies. The suitable temperature for laying hens in chicken battery cage is 18℃~25℃

2. Environmental regulation

The growth and development of laying hens are affected by factors such as temperature, humidity, light, harmful gases, fright, noise, environmental sanitation, disinfection, mosquitoes and flies.

The suitable temperature for laying hens is 18℃~25℃, and the egg production rate is best at 20℃. Adverse reactions during high temperature heat stress include pale cockscomb, anemia, reduced resistance, etc. The egg production rate drops by 10%-20%, and the average egg weight drops by 5%-10%. The decline in eggshell quality is reflected in thin-shelled eggs and broken eggs. , Soft-shelled eggs and non-shelled eggs increased, the mortality rate increased, and the damage to the fallopian tubes and ovaries was irreversibleof. Therefore, improving the ability of heat stress and preventing heat stress are the guarantee to ensure the economic benefits of laying hens in autumn. In the autumn, the temperature difference between day and night increases, and the invasion of cold air gradually increases, which will cause fluctuations in temperature. At this time, according to the weather changes, pay attention to keeping warm at night to avoid colds and respiratory diseases in chickens due to cold. Poorly ventilated chicken houses can cause insufficient oxygen.

Due to the high temperature and the large amount of water the chickens drink, the chicken manure becomes very thin, and it is easy to ferment to produce a lot of harmful gases such as ammonia and hydrogen sulfide, causing stress, which not only reduces the laying performance of the laying hens, but also easily triggers the respiratory tract of the chickens. disease. Among them, ammonia destroys the cilia and inner wall of the trachea, and viruses and E. coli enter the respiratory system, causing respiratory diseases.Especially these manufacturers buy Fully automatic poultry farming equipment for chicken

3. Feed preparation

The low egg production rate of hens is directly related to the feed, especially the content of vitamin A, vitamin D, pantothenic acid, niacin, folic acid, choline biotin, etc. in the feed. When the temperature is higher, the feed intake of laying hens is generally small. In general feed formulas, energy can meet their needs, and other ingredients such as vitamins will be insufficient, especially fat-soluble vitamins. Due to the influence of heat stress, laying hens need more vitamins, and the vitamins in the feed are affected by high temperature, the damage is intensified, and the content is reduced. Especially corn, its vitamin content is generally lower than that of fresh corn, and low-quality corn (such as mildew) is mostly marketed in autumn, which adds to the harm of poor quality of raw materials. The above factors caused the lack of fat-soluble vitamins required by the laying hens, which seriously affected the laying performance of the laying hens.

Chickens are naturally sensitive to mycotoxins, and low toxin content in the feed will cause a large number of deaths in the flock. Mycotoxins damage the body’s immune system and reduce the immune response. The effects on laying hens are concentrated in: decreased immunity, poor vaccine immunity; atrophy of ovaries and fallopian tubes, decreased egg production, and malformed eggs; reduced feed intake and production Decrease in performance, lower feed returns; lower hatchability of breeding eggs. The harm caused by different mycotoxins to laying hens is different. Among the known mycotoxins, ergot toxin, trichothecenes, fumonisin, and zearalenone have greater impact and toxicity on laying hens. , Aflatoxin, Ochratoxin, etc.

Due to heat stress, chicken intake is low. In order to ensure egg production, the energy level and nutrient concentration in the diet should be appropriately increased according to the chicken's feed intake, and the volume of the diet should be reduced to compensate for the nutritional intake caused by heat stress. Reduction in input.

How to reasonably control the ventilation of the incubator?

%AM, %21 %423 %2020 %09:%JulGood ventilation can keep the air in the incubators hatching eggs fresh and help the embryo develop well. In the late incubation period, the metabolism of chicken embryos is vigorous and the gas exchange volume increases. At this time, poor ventilation will seriously affect the hatching effect. However, in actual operation, we often encounter some doubts: the ventilation volume of the general incubator is controlled by the size of the opening damper.

In the cold winter, some incubators have poor thermal insulation facilities. When the air door is opened, the temperature of the incubator always fails to reach the set value; when the opening is small, there is concern about poor ventilation. In fact, electric incubators are equipped with high-speed rotating fans, which not only agitate the air in the incubator to make the temperature uniform, but also generate a large negative pressure when high-speed rotation can suck the air outside the incubator into the incubator.

Therefore, as long as the air door is not completely closed, as long as the fan does not stop, the fresh air from outside will continuously enter the incubator. At the same time, the turbid gas in the incubator will also be excluded from the incubator, so it will not have much impact on the hatching effect. Of course, if the ambient temperature in the incubator room can be relatively stable at around 20°C, the air door will be opened larger, the ventilation will be greater, and the hatching effect will be better.

In actual operation, under the premise that the temperature in the incubator can reach the set value, it is necessary to open the big air door to speed up the air circulation as much as possible. When the ambient temperature in the hatchery is low, the damper can be closed in the early stage of incubation, and ventilation and heat preservation should be taken into consideration in the later stage of the incubation. Generally speaking, the damper can be reduced by one level compared to the standard ambient temperature (20-24℃). How much influence will the reduction of ventilation have on the hatching effect.

One thing to note: In many models of incubators, the position of the air inlet and outlet and the rotation direction of the fan should not be changed at will. When the power is connected, if the sequence of a certain phase line is wrong, the fan may be reversed, which will seriously affect the gas exchange inside and outside the incubator, which will adversely affect the hatching effect.

What are the main equipment for large-scale chicken farming

%AM, %20 %378 %2020 %08:%JulDifferent automated chicken raising levels and different feeding methods have different requirements for equipment, but some are the most basic equipment, including chicken poultry farming equipment, drinking fountains, environmental control equipment, feeding equipment, egg collection equipment, manure cleaning equipment, etc.

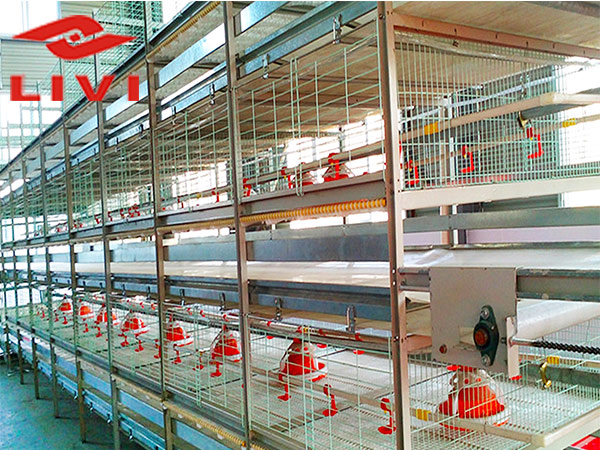

1. Chicken cage

Including brooding chicken cages, brooding chicken cages, layer cages, in some areas, using brooding integrated chicken cages can reduce a production link.

2. Egg collection equipment, feeding equipment and manure removal equipment

If the equipment used by manual operation is relatively simple, generally use egg carts, feed carts and manure carts. If automatic egg collection, automatic feeding and automatic manure removal are used, automatic egg collection, automatic feeding and automatic poultry manure removal system are required.

3. Environmental control equipment

Environmental control equipment, as the name implies, is equipment that controls the environment, which mainly includes the following parts:

Lighting equipment. The lighting equipment is mainly an automatic lighting controller. Able to turn on and off lights on time.

Ventilation equipment. The function of the ventilation equipment is to exhaust the dirty air, humidity and excess heat in the chicken house, and at the same time supplement fresh air. At present, large-diameter, low-speed axial fans are used for general chicken house ventilation. Wet pad fan cooling system. The main function of the wet mat fan cooling system is that summer air enters the chicken house through the wet mat, which can reduce the temperature of the air entering the chicken house and achieve a cooling effect.

Heating system. Electric heating, heating, coal stove, etc. can be used for heating. The more advanced is the hot blast stove heating system, which is mainly composed of hot blast stoves, axial fans, perforated plastic pipes, and air regulating doors. The device has simple structure, high thermal efficiency, fast heat delivery and low cost.

4. Drinking water system

Drinking equipment drinking equipment is divided into the following five types: nipple type, cup type, sink type, tower type and vacuum type drinking fountain. In the initial stage of chicks and free-range chickens, vacuum type, hanging tower type and sink type are mostly used. Nipple drinkers are not easy to spread diseases and consume less water. They can eliminate scrubbing work and improve work efficiency. It has gradually replaced regular water sinks, but the manufacturing accuracy requirements are relatively high. High, otherwise it is easy to leak.

More...

How to choose laying hen cages in the UK?

%AM, %17 %448 %2020 %09:%JulFarmers know that laying hen cages are the equipment that farmers most choose when raising chickens. Therefore, it is necessary to choose a cage suitable for chickens in order for them to grow healthily. Many farmers who raise chickens on a large scale will choose to go to the poultry equipment manufacturers for field inspections. However, recently there are many British customers who raise chickens in Ghana or Nigeria, but they only invest. They do not know if they choose a good chicken cage.

Poultry battery cages are the basic hardware equipment for caged chickens. Therefore, it is very important to choose a suitable cage and find a suitable layer cage manufacturer. So, how to choose a chicken coop? According to experience: different breeds of chickens are suitable for different cages. The author suggests that farmers should pay attention to the following points when purchasing chicken cages:

1. The viewpoint of the plan of rolling off the bottom of the laying hen cages. The point of view of the egg rolling at the bottom of the chicken cage must be precise. The small point of view cannot be rolled out of the egg in time. It may be trampled by the chicken. The large point of view simply falls to the ground and breaks, or the force of rolling the egg is so large that it breaks each other. The general slope of the cage bottom should be maintained at 7 to 8 degrees.

2. The distance of the iron bars at the bottom of the cage. The goal of the chicken cage is also very important. It is generally advocated that the distance is 2.5 cm × 5 cm. It is wrong to think that the size of the broiler breeder can increase the distance. It is recommended that chicken farms with sufficient funds be laid with a plastic net common to the bottom of the cage. Practice has proved that plastic nets can cushion the strength of eggs hitting the net and rolling down against the bottom of the net, not only greatly reducing the egg breaking rate, but also reducing the incidence of leg disease and pleurisy.

3. Pay attention to the connection between the bottom cage and the cage. Buyers need to be reminded here that they must pay attention to the handling of the connection between the cage and the cage. It must be done carefully, and no large open space should be left, because there are more eggs falling here. If you did not pay attention to check this detail when purchasing chicken cages, then it is recommended that you use plastic cable ties, thin wires or thin ropes to make a cross. You can add wooden or iron baffles to the cages at both ends of the chicken house. To prevent it from falling to the ground.

4. Raw material selection of chicken cage. The selection of manufacturing materials for chicken cages is very elaborate. The author recommends that suitable and resistant materials be selected. The diameter of the wire at the bottom of the cage is about 2 mm. The egg breaking rate is the smallest. The larger the wire diameter, the easier it is to form a broken egg.

How to maintain chicken farming equipment effectively?

%AM, %10 %376 %2020 %08:%JulUnder normal circumstances, automated chicken breeding equipment has a long service life, which can be as long as 10-20 years. But the premise is that under the condition of protecting the automatic breeding equipment. The cleaning and disinfection work of automated breeding equipment is very important, but it is also a very complicated work. Care must be taken while cleaning and disinfecting. The author will share with you how to maintain the poultry farming equipment.

1. The equipment must be carried out in strict accordance with the safety operation regulations, remembering that it cannot be overloaded to ensure the safety and reliability of the equipment, and any unsafe factors should be eliminated in time;

2. Regular refueling or oil change, no dry friction phenomenon, to ensure that the oil pressure is under normal filling, and the oil path is smooth;

3. The tools, etc. are placed neatly and the pipeline is organized;

4. Ensure that there is no oil leakage or air leakage in various parts of the equipment. Equipment maintenance includes what to clean up the surrounding debris.

Basic conditions for automation:

Equipment includes: heating equipment, ventilation equipment, water supply equipment, feeding equipment, egg collection equipment, manure removal equipment, cages, lighting equipment, etc.

Equipment disinfection equipment: agricultural sprayers, air pumps, etc.

Immunization and treatment equipment: continuous syringes, needles, etc.

Beak breaking equipment: electric beak breaking device, electric soldering iron, etc.

Weighing equipment: spring scales, pole scales, electronic scales, etc.