Summer broiler culture management considerations

%AM, %16 %422 %2019 %09:%Jul

In summer, the temperature is high, and various diseased bacteria are easy to breed, and the diseases in the flock culture are harmful. So how to manage high temperature in summer to ensure the survival rate of broilers?

1, reduce the density

Under high temperature conditions, if the breeding density is high, it is easy to cause heat stress. Therefore, to properly reduce the density of chickens, chicken farmers can eliminate those sick chickens, chickens and weak chickens in time, which reduces the density and avoids them. The casualties affect healthy flocks in chicken battery cages

2, adequate drinking water

In summer, the temperature is high, the chicken needs more water, and the water is clean. Unclean water is easy to cause disease. Therefore, chicken farmers should adjust the waterline in the summer to provide sufficient clean drinking water.

3. Electricity use matters

In summer, the wind turbine can't stop, the water curtain can't be broken. If it is power outage, it will cause many chickens to die. Therefore, we must ensure that the circuit is no problem. In addition, under high temperature and high load, electricity is prone to problems, such as fire, so pay attention to it. Protection.

4, weather changes

In summer, not only the high temperature, but also the windy and heavy rain, the chickens should pay attention not only to the temperature, but also the humidity, as well as the shock, leakage, and water that may be caused by heavy wind and heavy rain.

5, the chicken in the feed, the amount of heat that needs to be distributed is relatively large, the chicken farmers should avoid the time when the chickens emit heat, which is just the high temperature of the day, such as noon time. So summer feeding, usually in the morning and evening.

6, summer high temperature and high humidity, rain more, the feed is prone to mildew. In addition, in order to ensure that the feed does not become moldy after being ingested for a long time after entering the trough, the chicken farmers should ensure that the trough is cleaned once a day.

7, feed heatstroke cooling to pay attention to add heatstroke cooling products in the feed, the general summer chicken farmers need to add multi-dimensional, in order to improve the ability of the flock to resist heat stress in automatic layer rearing equipment in China.

8, the daytime cooling needs to pay attention, the evening ventilation can not be ignored. There are large differences in climate change in summer, so in order to improve the survival rate of broilers and reduce the losses of chicken farmers, these management matters are expected to be remembered.

How to disinfect chicken farm equipment more scientifically?

%AM, %16 %410 %2019 %08:%JulChickens are raised using poultry farming equipment. The density of chickens is relatively large and the number is large. Therefore, the sanitary environment and germs of the chicken houses will be more serious. It is necessary for the farmers to carry out regular disinfection before they can kill the pathogenic microorganisms in time, maintain the environment of the chicken house and reduce the prevalence of the chickens. Then, when the farmers are disinfecting daily, how can the chicken cage equipment be disinfected to be more scientific and effective?

1. Clean the house before disinfection: In order to ensure the disinfection effect, the farmers should pay attention to the thoroughness of the roof, walls, chicken house passages and dust on the chicken cage equipment before the disinfection. Cleaning to improve disinfection and save drug use.

2. Reasonable choice of disinfection drugs: The effect of disinfection has a direct impact on the choice of disinfectant drugs. Therefore, when selecting disinfectant drugs, farmers should pay attention to the selection of broad-spectrum, high-efficiency, strong bactericidal effects but low toxicity, irritating, no residue, and less corrosive to metal and plastic products. Farmers can choose according to their actual situation and local varieties.

3. Scientific preparation of disinfecting drugs: Disinfecting drugs need to be formulated according to a certain proportion of water. When preparing disinfectant drugs, farmers should pay attention to selecting deep well water or tap water with less impurities, and pay attention to the water temperature control at 30~45 °C. Another important point is that after dilution of the sterilized medicinal water, the stability will be worse, so the farmer must be ready to use now, once used up, the prepared disinfectant can not be stored.

4. Choose a reasonable disinfection method: There are many ways to disinfect chickens. At present, the main method of disinfecting chickens is spray disinfection. It is recommended that farmers can choose high-pressure power sprayers or knapsack sprayers. The top of the house is sprayed in a circle, and the diameter of the fog is 80 to 120 microns. If the fog is too small, it can easily be inhaled into the respiratory tract by the chicken, causing pulmonary edema. In severe cases, it may also induce respiratory diseases. However, if the fog is too large, it may cause uneven spray and increase the humidity of the house.

5. When using spray disinfection, it is necessary to master the frequency of spray disinfection and the amount of spray: the effect of disinfection is not continuous, so farmers need to be disinfected regularly. It is recommended that farmers should disinfect at least once a week. It is also recommended that farmers should not carry out chicken spray disinfection during the brooding stage, but they can be disinfected with chicken after 1 week of age. However, it is necessary to pay attention to the general amount of spray, calculated from 30 to 50 ml per square meter. The amount of chicks sprayed was less, and the amount of medium-sized chickens sprayed was more.

The above is what the author told the farmers, how to disinfect the equipment more scientifically in the process of raising chickens using poultry farming equipment. In addition, the farmers should also be reminded of the following problems. If the chickens are vaccinated, the farmers should not be able to disinfect the chickens within 3 days before and after the immunization, so as not to affect the immune effect.

How to choose the size of the chicken cage when buying chicken cage?

%AM, %12 %399 %2019 %08:%JulUsers who know or have used chicken cages know that chicken cage equipment is divided into many types and sizes. When farmers choose the size, they must not blindly choose. Do not think that the larger the size, the more chickens that can be raised. Or refer to various needs to choose the specific type and size. The following authors refer to the experience of poultry equipment suppliers to tell farmers how to choose the size of the chicken cage.

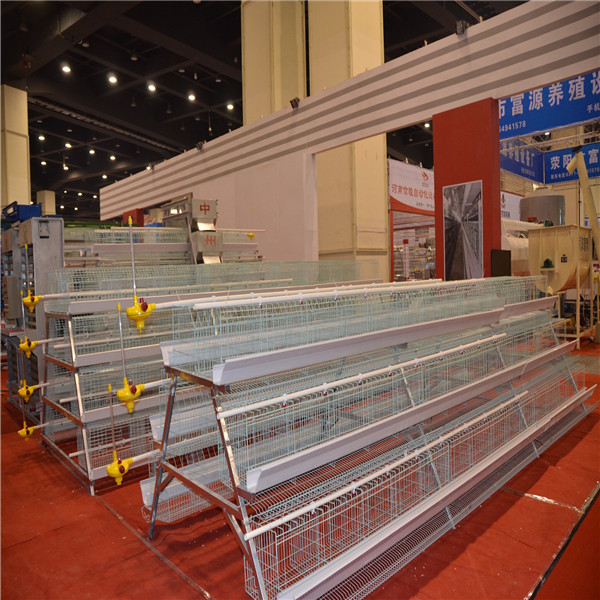

1. The chicken cages on the market are divided into three types according to different varieties of chicken: egg cages, broiler cages and brooding cages. Farmers should choose the type of cage according to the breed they breed. The appropriate type is the premise of choosing the size of the cage.

2. Although the size of the chicken cages supplied by various manufacturers is relatively large, the area of each farmer's house is also different. Therefore, chicken cages come in a variety of sizes to cater to the size of each farmer's house and allow farmers to choose the right size. Therefore, when the farmers purchase, they should choose according to the size of their own house. If you don't know how to determine, you can consult the manufacturer's technical staff, who will recommend the appropriate layer cage size based on the size of your house.

3. When selecting the size of the chicken cage, the farmer needs to focus on the number of layer or broiler chickens to be cultured. The number of egg chickens that can be cultured in different cage sizes is different, so each size can be cultured. The number must also be carefully consulted with each manufacturer.

4. If the farmer has not built a chicken house or has no experience of himself, the area of the house to be built does not meet the size of the cage. Farmers can consult the technicians of poultry equipment manufacturers, who can carry out independent upgrades, design and transformation services according to your needs.

5. In addition, when selecting the size of the chicken cage, the farmers should also consider the development of the chicken house and the chicken industry. Now the chicken industry is popular with automatic chicken raising, so the farmers should choose the size of the egg cage. Considering the need to install automated chicken equipment to assist in raising chickens, if the size of the egg cage is required, it should be selected according to the area occupied by the automation equipment.

The above is the four points of sharing, on the tips and methods of how to choose the size of the poultry battery cages, I hope that the above description can help the farmers.

The Laying hen healthy breeding technology

%AM, %12 %386 %2019 %08:%JulThe daily operation points of laying hens include drinking water. Feeding and disinfection, drinking water not only needs water line cleaning. It is best to disinfect with drinking water for 1.2 weeks per month. Let the chicken use clean and pure water. Improve chicken resistance. 2. After the light is turned on and 2 to 3 hours before the light is turned off, it is the peak of the feeding of the laying hen. These two time periods must be guaranteed. Let the chickens eat well. For this purpose, feed at least 2 to 4 times a day. Every time you need to add less feed to ensure that the chickens are finished. And there must be empty slots. Not only let the chickens eat but also eat well. Ensure that the chickens are evenly weighted. Promote the growth of the flock. Prepare to improve the performance of laying hens in poultry cage equipment.

Strengthen the sanitation and disinfection inside and outside the chicken house. Regular disinfection of drinking utensils. For conditional breeders, it is necessary to disinfect the chicken twice a week. Pay attention to the environmental disinfection work on the field. And eliminate weeds around the house and in the field. Do a good job in environmental sanitation. Lighting management points, chick lighting time. The first day is 23 hours. After that, it will be reduced by 0.5 hours. It will be maintained until 12 to 13 hours, during which time the length of the light will be prolonged or shortened with the weight. It is not recommended that chicks give light for 24 hours on the first day. Can not even 24 hours of light for several days. In this way, the chicks are prone to fatigue, the rest is not good, and the immunity of the chickens is reduced.

The temperature in the house is best kept between 15 °C and 25 °C. The temperature difference in the house should not exceed 7 within 24 hours. C, the best is kept within 4 degrees. The relative humidity of the house should be kept at 55%. 65%. Chicks or Southern Chicken Houses are 60%. 70%. At the same time, pay attention to the ventilation of the chicken house.

Controlling the air quality of the house in the spring

%AM, %10 %409 %2019 %08:%JulLarge-scale chicken raising is the choice of raising chickens in the chicken house. The air quality of the chicken house is a good condition for determining whether the chicken is raised. The air pollution source of the chicken house is mainly composed of dust, harmful gas and Harmful microorganisms. Chickens excrete feces and breathing can also produce harmful gases.

Control of air pollution in chicken houses

1, Using granular material, under the condition of ensuring the normal physiological demand of the chicken, the coarser grain is better than the fine grain material; the feeding wet material is better than the dry material.

2, Regularly open the exhaust device to discharge the dirty air. Try not to use or use less litter in poultry equipment manufacturer in china.

3, 5 to 8 sprays per day in the winter house, can reduce the dust in the house by 40% to 70%.

4, timely removal of manure, cleaning the ground, can reduce the content of ammonia in the air of the house.

5, according to the requirements of chicken body surface parasite prevention, reduce the scum and broken hair caused by chicken scratching. Kill insects and rodents in the house and reduce the chance of bringing in harmful microorganisms.

6, to have sufficient light, the sun's ultraviolet rays can effectively kill harmful bacteria in the air, reduce the incidence of infection, ensure safe feeding.

Misconceptions about cooling down using poultry farming equipment

%AM, %10 %392 %2019 %08:%JulIn the process of raising chickens using poultry farm equipment, it is a must for the farmers to carry out heatstroke prevention and cooling of the chickens in the chicken houses. Scientific and effective cooling can ensure the healthy growth of the flock, as well as a comfortable growth and production environment, and reduce the stress caused by flocks in summer. However, many farmers have failed to master the cooling technology and blindly carry out the cooling work. The result is counterproductive. Here are some common mistakes for the farmers to tell about the cooling of chickens.

1. Only pay attention to the heatstroke prevention and cooling work of laying hens: Many farmers only pay attention to the cooling work of laying hens during the laying period, and do not pay attention to the broiler chickens in the breeding stage, and think that the impact is not great. In fact, as the age increases, the required ambient temperature should gradually decrease. If it is in the first week of the chick, because the required ambient temperature is 32 ~ 35 ° C, the impact is not significant. In the second week, and even later, the required ambient temperature drops 1 °C every 3 days until it drops to 21-18 °C. If it is summer brooding, the outside temperature is often above 30 °C. When the ambient temperature is too high, the feed intake of the chicks will also decrease due to the influence of high temperature, thus affecting the growth and development of the chicks. High temperatures lead to reduced feed intake and lighter weight of chickens, which can affect the production and sustained high yield of chickens.

2. Planting too many leafy trees: Many farmers will plant trees around them when they build the house. They think that they can shade and reduce the temperature of the house. Although the starting point is good, there are more trees and more trees. All kinds of birds, insects, mosquitoes, etc. will increase, and these insects are the source of the disease, which will lead to a major outbreak in the chicken farm. The best way is to use a shade net around the house. If a wet curtain is installed in the house, a sunshade net can be installed outside the wet curtain to prevent direct sunlight and weaken the cooling effect of the wet curtain.

3. The chicken feed is processed too fine: the high temperature in summer will cause the drinking water of the chicken to increase, so the farmer can see the granular feed when the feces are produced every day. The farmer thinks that the chicken is not digested and the feed is processed. Finer, it is good for digestion, but this is the wrong concept. The drinking water of chickens in the hot season is 4 times that of the low temperature season. Therefore, the feed intake in the hot season is reduced, the amount of drinking water is increased, and the granular feed in the feces is directly discharged. This is a normal phenomenon. Farmers do not have to worry too much because of drinking water. Many chickens do not have a special urination organ, so the water that is drunk will be quickly discharged with the cloaca, causing some feed to stay in the digestive tract for a shorter period of time and not completely digested. If the chicken feed is processed too fine, the palatability will be worse, resulting in a further reduction in the feed intake of the chicken and a greater impact.

4. Add too much sodium bicarbonate in the water: Many farmers want to help the chicken to cool down, add sodium bicarbonate in the drinking water, or add vitamin C at the same time. The addition of sodium bicarbonate can effectively regulate the acid-base balance in chickens and significantly improve the ability of chickens to resist heat stress. This is a misconception.

If the figure is convenient, adding sodium bicarbonate in water, because of the large amount of drinking water in summer chickens, means that the amount of sodium bicarbonate ingested is large, and excessive intake may cause poisoning, so it is best to add it to the feed. Vitamin C is easily destroyed in water and reduces the effect. It is recommended that farmers can add it to the feed. In addition, vitamin C sodium bicarbonate cannot be used at the same time, which will reduce the efficacy. Therefore, vitamin C is used in the early stage of the high temperature season and sodium hydrogencarbonate is preferred in the later stage.

5. Improper drinking water immunization: In order to prevent outbreaks of infectious diseases in chickens during the hot season, it is best to vaccinate through drinking water. However, when drinking water immunization, the farmers must carry out the above process reasonably, the selection of vaccines, the correct method of preparation and drinking water immunization, etc., must be mastered by the farmers, otherwise the phenomenon of drinking water immune failure is easy to occur.

The above five points are the authors summarized for the farmers, in the process of using chicken battery cages to raise chickens in the hot season, the farmers have some misconceptions and practices in the heatstroke prevention and cooling work. It is hoped that the farmers will avoid the mistakes in the future feeding process through the above understanding.

How to choose poultry farming equipment for the new chicken farm?

%AM, %05 %413 %2019 %08:%JulSelect equipment of different materials, and also increase or decrease equipment according to different breeding stages.

1. Choosing chicken cage equipment needs to fully consider the geographical and environmental factors, not only to see its completeness, the chicken farm needs a farming process, not just to play a role. Select equipment of different materials, and also increase or decrease equipment according to different breeding stages.

2. For chicken farms, chicken cages are one of the indispensable chicken equipment. Good chicken cages can provide a comfortable living environment for chickens.

3. In the selection process of the chicken cage, it is necessary to consider the equipment with it, such as drinking water equipment, feeding equipment, and clearing equipment can be used in combination.

First of all, it is necessary to purchase a set of poultry farm cages for breeding. When the farmers purchase the cages, they can consult the manufacturers according to their actual feeding conditions. Nowadays, the cages sold on the market are made by hot-dip galvanizing process, and the service life is as long as 15-20 years, so that the farmers can save a lot of money in the breeding cost during the years of using the breeding equipment. Moreover, the use of cage farming can reduce the use of the house area, and the cage mode greatly reduces the farmland, which will also save the farmers a large amount of rental funds.

Because chickens are restricted to activities in cages, the phenomenon of food competition is reduced, the development is neat, and the weight gain is good, which can increase feed efficiency by 5%-10% and reduce total cost by 3%-7%. Nowadays, the cage mode is generally that the three-layer cage chicken body is not in contact with the feces, which can effectively control the spread of Blight and coccidiosis. Use this mode to eat evenly, grow quickly, and can be released 3-5 days in advance.

Pay attention to the connection between the cage and the bottom of the cage. Remind the farmers that there is not a big gap here, because there are more eggs to be dropped here. You must pay attention to this detail when buying the cage. After that is the material selection of the cage. To choose suitable materials with toughness, it is not easy to deform, hot-dip galvanizing does not rust, does not rot, and has a long service life.

Drinking water management for chicks

%AM, %05 %408 %2019 %08:%JulAfter the chicks are connected to the brooding house, the first drinking water is called the first drink, also known as boiling water. The first drink has an important role in timely replenishing chicken body water, relieving stress and promoting meconium excretion. The first drink should be arranged before the chicks are placed in the brooding house and before the food is opened. The utensils for the first drink are small vacuum drinkers. It is best to use cold water. For chicks after long-distance transportation, oral rehydration salts should be added to the drinking water to help regulate body fluid balance. Place the drinker in the middle of the flock and gently tap the water polo with your fingers. Most chicks will drink water next to the drinker. For chicks without drinking water, the crotch should be immersed in the drinker to induce drinking water.

Drinking water management

To ensure good drinking water quality, the drinking water should be clean. It is best to drink cold water, and then switch to deep well water or tap water. In order to ensure good drinking water quality, it is necessary to regularly clean and disinfect drinking utensils. When using a vacuum drinker, the water in the drinker is usually changed 2 or 3 times a day, and each time the water is changed, it must be cleaned and disinfected. Ensure that the number of drinking water supplies for adequate drinking water is sufficient in poultry farm equipment manufacturer

More...

Summer integrated management method for chicken houses

%AM, %03 %419 %2019 %09:%Jul

The high temperature in summer is very uncomfortable, and the chicken is an animal without sweat glands. So what kind of management methods should be used to raise chickens in summer?

The first is the way of cooling and cooling. It is a good practice to choose the water curtain cooling system. The basic principle is the principle of water evaporation and heat absorption. The external high temperature air is usually unsaturated, and the unsaturated hot air acts under the negative pressure of the induced draft fan. Under the wet curtain, the vapor pressure of the water is higher than the vapor pressure of the air, causing the water to evaporate and take away the moist heat in the air, so that the gas is cooled, the air after the cooling enters the chicken house, and flows from the one end in a laminar flow state. At the other end, the door is finally discharged, so as to achieve ventilation, cooling and ventilation in automatic poultry farming.

When the curtain is cooled, attention should be paid to the tightness of the house. Except for the water curtain and the fan outlet, the rest must be sealed to prevent the short circuit of the hot air and affect the cooling effect. Always check whether the equipment is intact and damaged, and repair it in time. If the chicken is short of water in the hot season, it will increase the degree of heat stress and even lead to a large number of deaths. Therefore, in the breeding season, if you encounter hot weather, you must ensure that the breeder supplies water throughout the day. In the case of ensuring safety, all immunization activities should avoid hot weather as much as possible. For chickens in the laying period, in addition to drinking water immunity, other immune activities are best arranged after the lights are turned off at night.

In addition, the house can use a shade net to prevent direct sunlight from lowering the temperature of the house. If necessary, add some anti-stress additives to the drinking water, or reduce the stocking density of the house. The extent of heat stress.

How to adjust the feed of laying hens in the hot season?

%AM, %03 %414 %2019 %08:%JulAs the temperature rises, the season of high temperature and high humidity is ushered in. Chickens are often under heat stress, and the intake of feed is significantly reduced, resulting in insufficient intake of various nutrients, affecting the health and production performance of laying hens. Under such conditions, rational adjustment of feed nutrient levels and feeding methods is also an effective means to improve the performance of chickens in chicken battery cages.

1. Appropriate increase in feed nutrient concentration

When the ambient temperature exceeds 25 °C, the feed intake of the chicken will be correspondingly reduced, and the intake of nutrients will be correspondingly reduced, resulting in a decrease in egg production performance and a poor quality of the eggs. The nutritional concentration of the diet is compensated. In the hot season, the energy of the laying hens needs to be reduced by 0.966 MJ per kg of feed metabolism compared to the usual feeding standard. Therefore, some experts believe that the energy concentration of feed should be appropriately reduced in the hot season. However, after the laying hens are born, energy is the key to determining the egg production rate. At high temperatures, energy intake is often insufficient due to reduced feed intake, which affects egg production rate. Tests have shown that the egg production rate can be significantly increased after adding 1.5% cooked soybean oil to the feed during high temperature. To this end, it is necessary to appropriately reduce the amount of cereal feed such as corn, so that it generally does not exceed 50% to 55%, and at the same time appropriately increase the nutrient concentration of the feed to ensure the normal performance of its production performance.

2. Increase the supply of protein feed as appropriate

As the weather gets hotter, the feed intake of chickens is reduced. Only by increasing the protein level in the feed as appropriate, and ensuring the amino acid balance, it is possible to meet the protein needs of the laying hens. Otherwise, the amount of egg production will be affected by insufficient protein. The protein content of the laying hens in the hot season should be increased by 1 to 2 percentage points over the other seasons, reaching more than 18%. Therefore, it is necessary to increase the amount of cake meal such as soybean meal and cotton kernel cake in the compound feed, and the dosage is not less than 20% to 25%. The amount of animal protein feed such as fish meal should be appropriately reduced to increase palatability and increase feed intake.

3. Careful use of feed additives

In order to avoid the stress reaction and egg production performance of laying hens caused by factors such as high temperature, it is necessary to add some anti-stress additives in feed or drinking water. For example, the addition of 0.1% to 0.4% vitamin C and 0.2% to 0.3% ammonium chloride in drinking water can significantly alleviate heat stress. According to the data, adding 0.04% bacitracin to the diet can maintain the balance of the flora in the intestine, promote nutrient absorption, increase the feed conversion rate, and also have anti-stress effects. Adding 0.1% fumaric acid to feed or drinking water can effectively alleviate heat stress, increase feed intake and increase egg production rate. In the stress state of high temperature and high humidity, adding 0.3% sodium bicarbonate to the feed has a significant effect on improving the heat resistance and egg production rate of the laying hen, and at the same time greatly reducing the egg breakage rate. But be sure to pay attention to the amount of additives to prevent counterproductive.

4. Rational use of mineral feed

In the hot season, the phosphorus content in the diet should be appropriately increased (phosphorus can relieve heat stress). At the same time, the calcium content in the laying hens diet can be increased to 3.8% to 4%, try to achieve calcium and phosphorus balance, and maintain a ratio of calcium to phosphorus of 4:1. However, too much calcium in the compound feed will affect palatability. In order to increase the intake of calcium, it does not affect the palatability of the feed of the laying hen. In addition to increasing the amount of calcium in the feed, it can be supplemented separately to allow the chicken to eat freely to meet its physiological needs.

The above is the author's summary of the points that farmers need to pay attention to when using poultry farming equipment. Farmers are encouraged to use the method flexibly, and the specific situation is analyzed.